Method for removing free calcium oxide and magnesium oxide in converter steel making slag

A technology of free calcium oxide and converter steelmaking, which is applied in the field of magnesia and digestion of free calcium oxide in converter steelmaking waste slag, which can solve the problems of low operation safety, water consumption and complicated operation, and achieve good digestion effect and reduce The effect of environmental pollution and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below with laboratory small-scale test examples.

[0016] Concrete steps of the present invention:

[0017] a. Crushing, the converter steelmaking waste slag is put into the jaw crusher for crushing, and the crushing particle size is ≦0.5mm.

[0018] b. Sieve, sieve the crushed steel slag according to three different particle sizes of 0~0.1mm, 0.1~0.22mm, 0.22~0.5mm, and place them separately.

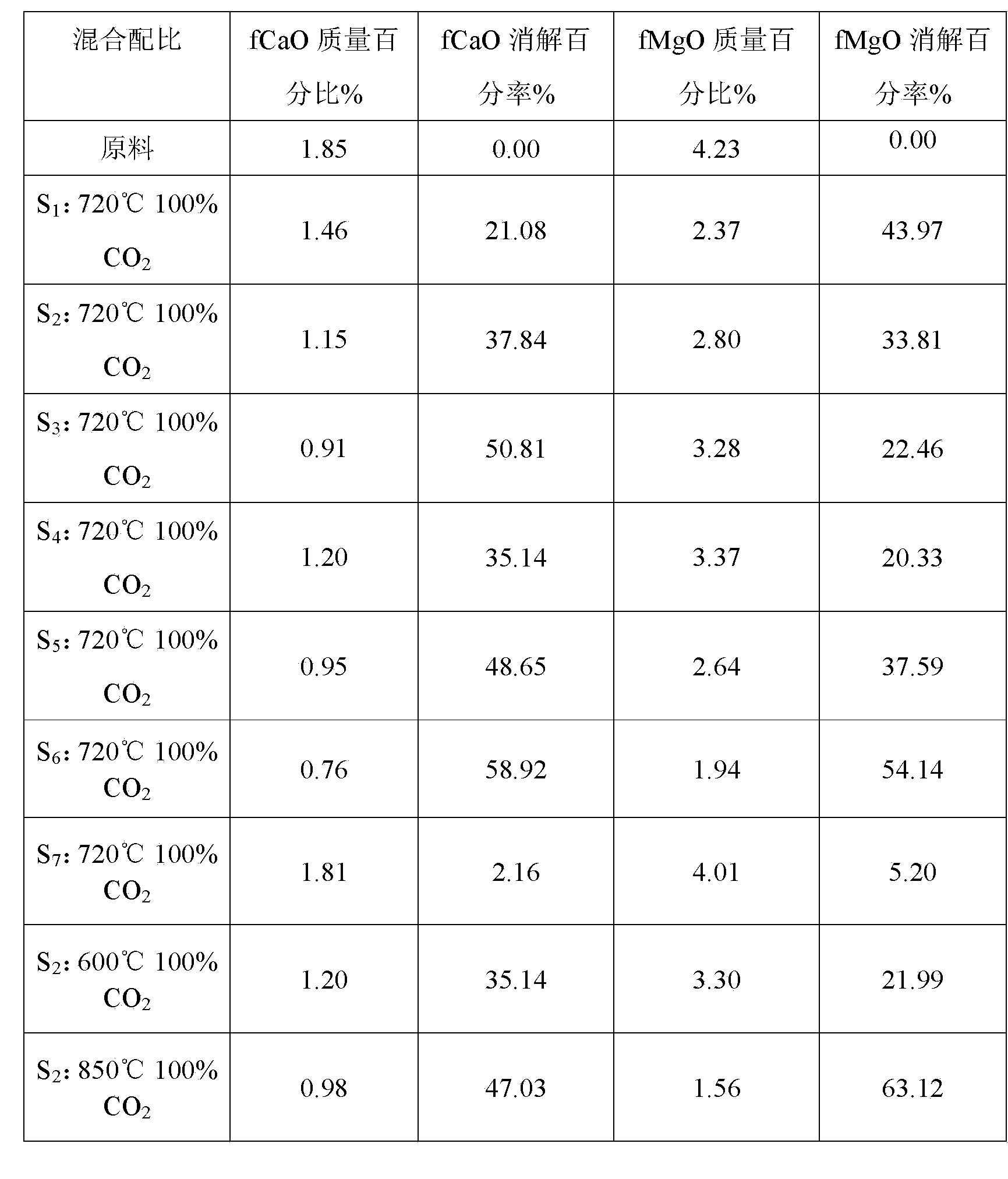

[0019] c. Mixing, mixing steel slag of different particle sizes according to the mass percentage ratio. Table 1 lists seven mixing ratios:

[0020] Table 1 Mixing ratio of steel slag with different particle sizes

[0021] steel slag

0~0.1mm

0.1~0.22mm

0.22~0.5mm

Proportion one (S 1 )

75%

10%

15%

Proportion 2 (S 2 )

65%

20%

15%

Proportion three (S 3 )

55%

30%

15%

Proportion four (S 4 )

45%

40%

15%

Proportion five (S 5 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com