Catalyst for producing polyurethane plate

A catalyst and polyurethane technology, applied in the direction of organic chemistry, reductive alkylation preparation, etc., can solve the problems of poor fluidity, unable to fill the mold cavity, unable to make polyurethane products, etc., to improve fluidity and low production and processing costs , the effect of high quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

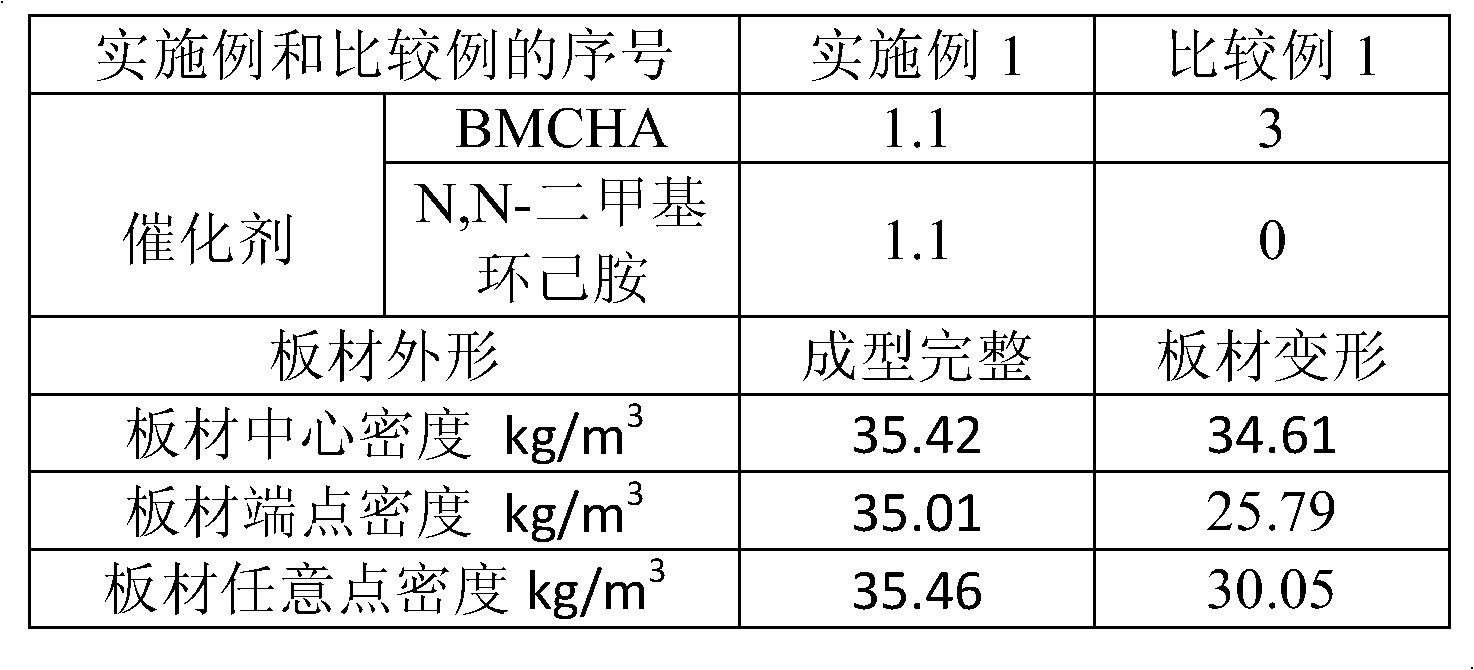

Embodiment 1 and comparative example 1

[0025] The present invention will be described below based on Examples and Comparative Examples.

[0026] Use 100 parts by weight of polyether polyol as a polyol component, 200 parts by weight of isocyanate, 2 parts of 1,4 butanediol as a crosslinking agent, and for every 100 parts by weight of a polyol component (polyether polyol and crosslinking agent ) using the catalyst with the composition shown in Table 1 in the amount shown in Table 1, and mixing the polyol component and the catalyst to obtain a polyol solution.

[0027] A polyurethane pouring machine is used to mix the aforementioned polyol solution and pour it into a mold to obtain a molded polyurethane sheet.

[0028] The obtained polyurethane board is evaluated from two aspects: whether the shape of the board is complete or not and the foam uniformity of the board.

[0029] The uniformity of the foam is manifested in two aspects: one is that the sample block is taken out at any point, and the cell uniformity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com