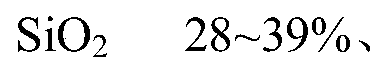

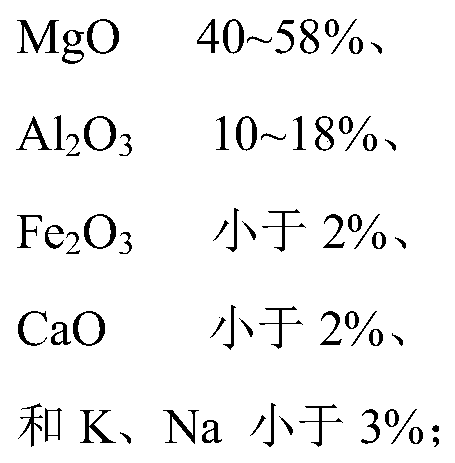

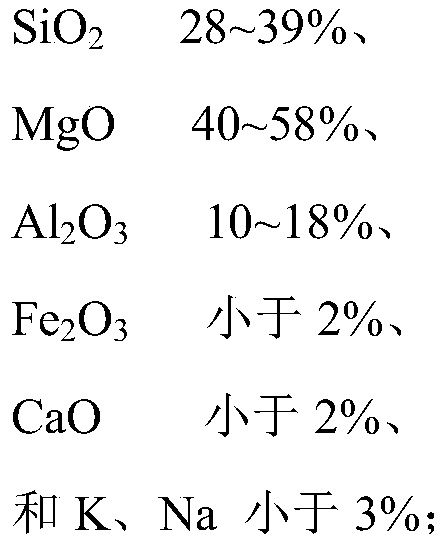

A kind of forsterite light heat insulation refractory material and preparation method thereof

A refractory material, lightweight heat insulation technology, applied in the direction of ceramic products, other household appliances, household appliances, etc., can solve the problems of high requirements and high product prices, and achieve high porosity, low re-burning line shrinkage, and pore size. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Raw materials: nickel slag, silicon-manganese slag, fly ash, the mass ratio of the three is 15:45:40, plus 15% rice husk; among them, 15% rice husk refers to rice husk and main material (nickel slag + waste magnesium brick + fly ash) is 15% by mass.

[0027] Preparation:

[0028] (1) Raw material pretreatment: nickel slag and silico-manganese slag are crushed and ground for 0.5-4 hours to obtain nickel slag and silico-manganese slag powder; rice husk is boiled with 10% HCl solution for 1-2 hours, and then washed with water clean, and finally crushed and ground for 1h to 3h to obtain rice husk powder;

[0029] (2) Ball mill mixing: nickel slag powder, silicomanganese slag powder, and fly ash powder are weighed in a mass ratio of 15:45:40, plus 15% rice husk powder, and ball milled for 2 hours;

[0030] (3) Molding: compression molding to obtain green body;

[0031] (4) Firing: 20°C to 500°C, heat up for 96 minutes, hold at 500°C for 30 minutes, 500°C to 1000°C, heat u...

Embodiment 2

[0035] Raw materials: nickel slag, chromium slag, waste magnesia bricks, sludge, the mass ratio of the four is 15:15:48:22, plus 5% straw, 5% carbon powder: among them, 5% straw refers to straw and main material ( The mass ratio of nickel slag + chromium slag + waste magnesia brick + sludge) is 5%, and 5% carbon powder means that the mass ratio of carbon powder to main material (nickel slag + chromium slag + waste magnesia brick + sludge) is 5%. %.

[0036] Preparation:

[0037] (1) Raw material pretreatment: Nickel slag, chromium slag, waste magnesia bricks, and sludge are crushed and ground for 0.5-4 hours to obtain nickel slag, chromium slag, waste magnesia brick, and sludge powder; the volume fraction of straw is 10% HCl solution is boiled for 1-2 hours, then washed with water, finally crushed and ground for 1-3 hours to obtain straw powder;

[0038] (2) Ball mill mixing: nickel slag powder, chromium slag powder, waste magnesia brick powder, and sludge powder in a mass r...

Embodiment 3

[0044]Raw materials: chromium slag, waste magnesia bricks, coal gangue, the mass ratio of the three is 26:43:31, plus 10% charcoal, 2.5% boric acid; 10% charcoal refers to charcoal and main materials (chrome slag + waste magnesia bricks +coal gangue) is 10%, and 2.5% boric acid means that the mass ratio of boric acid to main material (chrome slag+waste magnesia brick+coal gangue) is 2.5%.

[0045] Preparation:

[0046] (1) Raw material pretreatment: chrome slag, waste magnesia brick, coal gangue are crushed and ground for 0.5-4 hours to obtain nickel slag, waste magnesia brick, and coal gangue powder; charcoal is boiled with a volume fraction of 10% HCl solution for 1-2 hours 2h, then washed with water, finally crushed and ground for 1h-3h to obtain charcoal powder;

[0047] (2) Ball mill mixing: take nickel slag powder, waste magnesia brick powder, and coal gangue powder in a mass ratio of 26:43:31, add 10% charcoal powder, 2.5% boric acid, weigh, and ball mill for 2 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com