Foamer composition, polyurethane rigid foam, preparation method of foamer composition, refrigeration equipment and thermal insulation component

A technology of rigid foam and refrigeration equipment, applied in the field of blowing agent composition, to achieve the effects of reduced consumption, low thermal conductivity and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

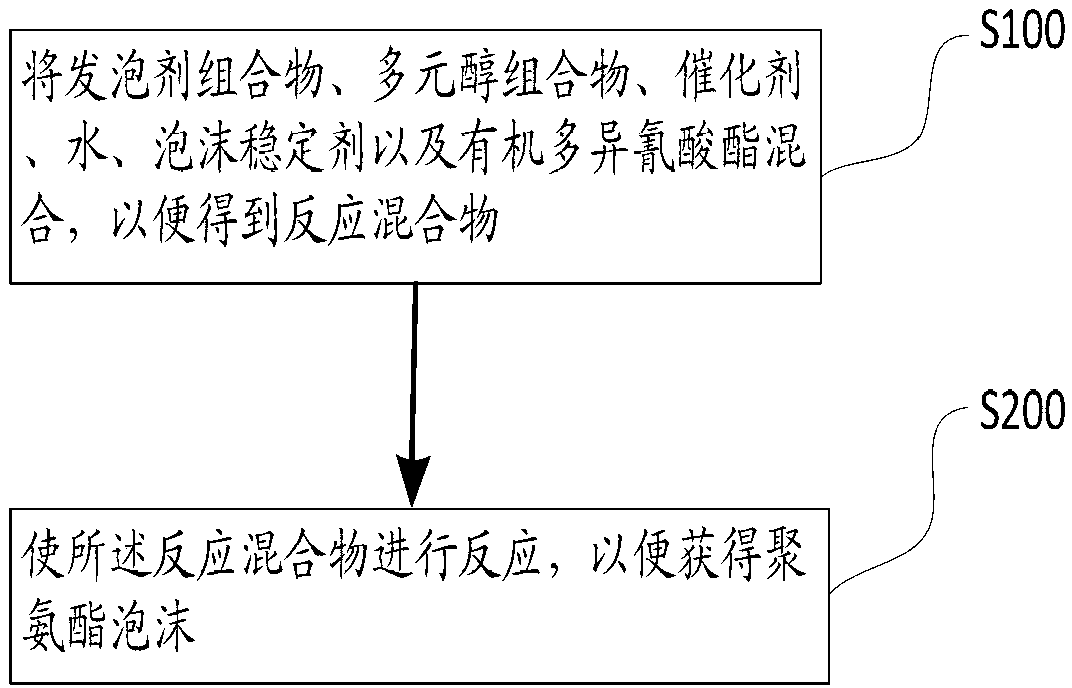

Method used

Image

Examples

Embodiment 1、2

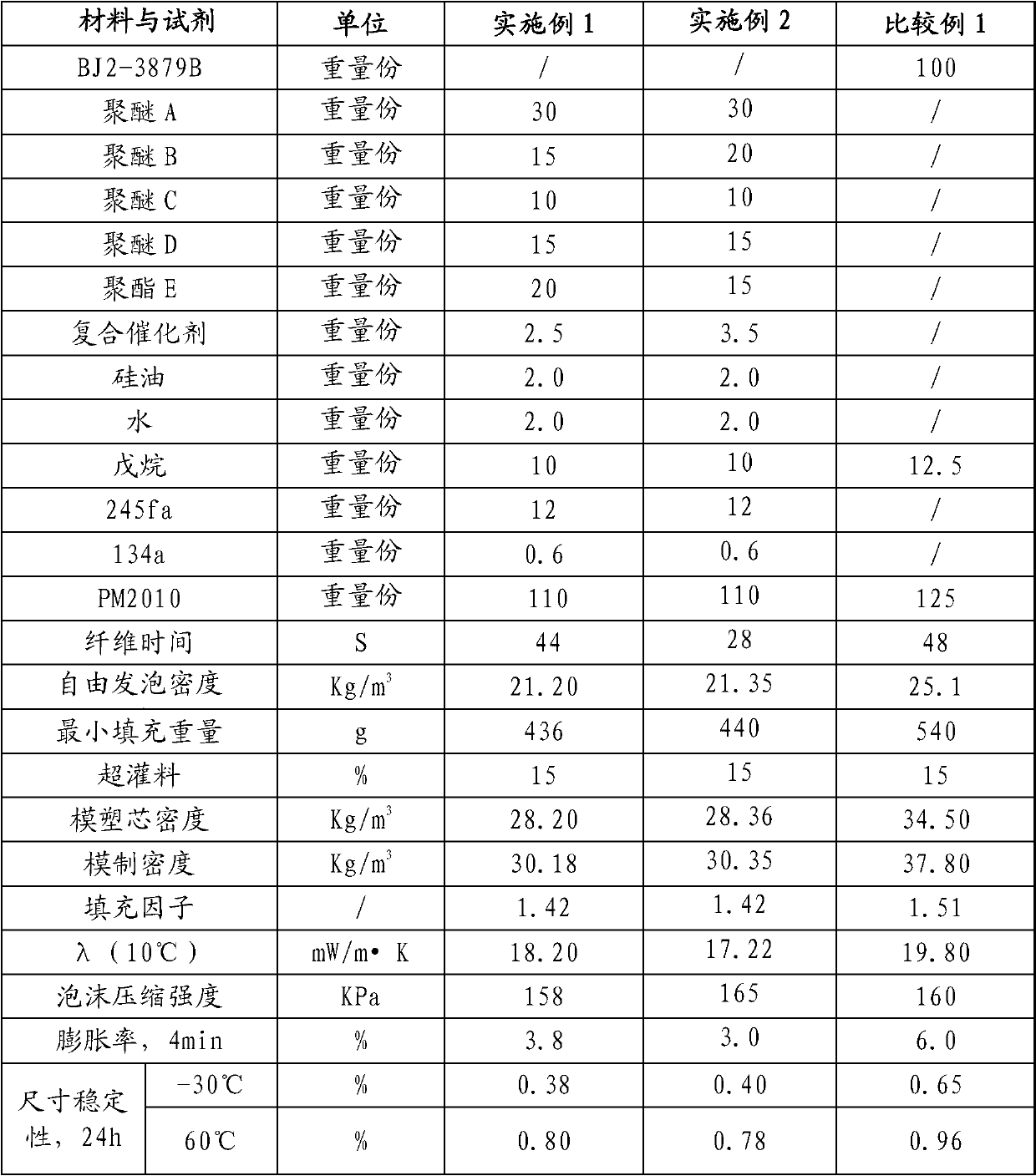

[0104] Polyurethane rigid foams were prepared following the procedure described in General Methods.

[0105] The BJ2-3879B used in Comparative Example 1 in Table 1 and Comparative Example 2 in Table 3 is a combined polyether of pure cyclopentane system currently used in industry.

[0106] In embodiment 1 and embodiment 2 all adopt the blowing agent composition of the pentane of 10 weight parts, the 245fa of 12 weight parts and the 134a of 0.6 weight part, and comparative example 1 adopts the BJ2-3879B of 100 weight parts and 12.5 weight parts The blowing agent composition of pentane, but the content of aromatic polyether polyol and aromatic polyester polyol used by the three is different (see Table 1), and then prepare polyurethane rigid foam respectively, and finally detect relevant parameters, The test results are shown in Table 1.

[0107] As shown in Table 1, compared with the foam of Example 1 and Comparative Example 1, it can be seen that the fluidity of the former foam...

Embodiment 3-5

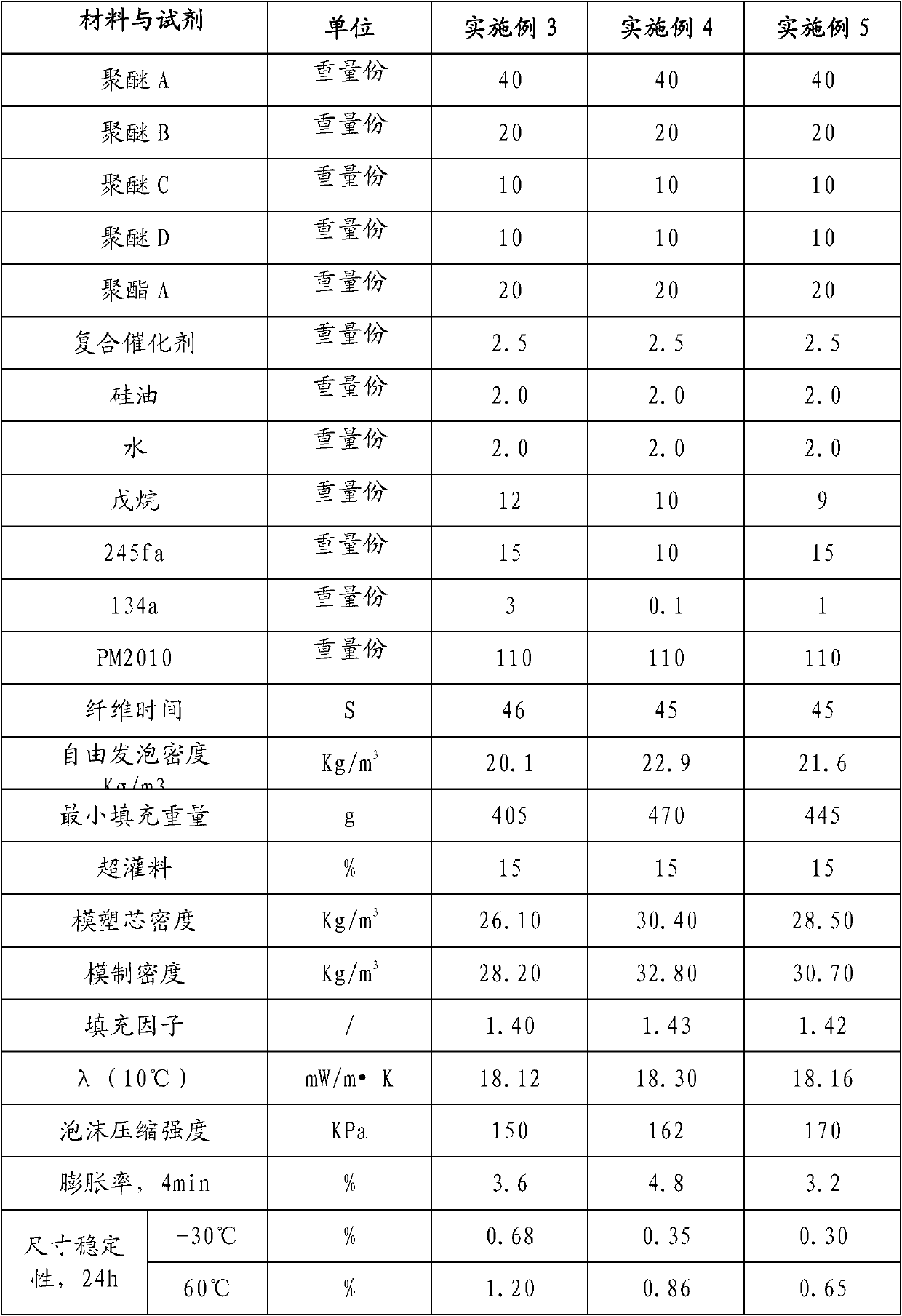

[0113] Using the components shown in Table 2, polyurethane rigid foams were prepared following the procedure described in General Methods.

[0114] In embodiment 3, 4 and 5, all adopt the blowing agent composition of pentane, 245fa and 134a, but the ratio of blowing agent pentane, 245fa, 134a used by the three is different, and the purpose of this design is to use this To verify the effect of blowing agent on foam performance, relevant information is shown in Table 2. In the embodiments, weighing the blowing agent according to the upper limit, lower limit and middle value of the weight ratio can be implemented.

[0115] It can be seen from Table 2 that by changing the proportion of blowing agents pentane, 245fa and 134a, the density of the foam can be significantly changed, but the thermal conductivity, expansion rate and compressive strength of the foam are less affected.

[0116] Table 2

[0117]

Embodiment 6

[0119] Polyurethane rigid foams were prepared following the procedure described in General Methods. Example 6 uses the refrigerator made from the foam prepared in Example 1, and Comparative Example 2 uses the refrigerator made from the foam prepared in Comparative Example 1. See Table 3 for information about the foam used. The experiment chose to make the same refrigerator model on the same equipment. The refrigerator is a 3-door refrigerator with a foam thickness of 90mm in the freezer, 65mm in the freezer and 65mm in the variable room. The normal demoulding time of the refrigerator is 6 minutes. After the refrigerator is demoulded, measure the expansion rate (in mm) of the top, middle, and bottom of the left and right sides of the box. The difference between the maximum and minimum values at each point should be less than 2mm. The test results are shown in Table 3. As can be seen from Table 3, compared with Comparative Example 2, Example 6 has better foam fluidity and dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com