Ceramic silicon rubber and preparation method thereof

A technology for ceramicizing silicone rubber and rubber, applied in the field of rubber materials, can solve problems such as affecting the overall function, changing the color of silicone rubber, and affecting the mechanical properties of silicone rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

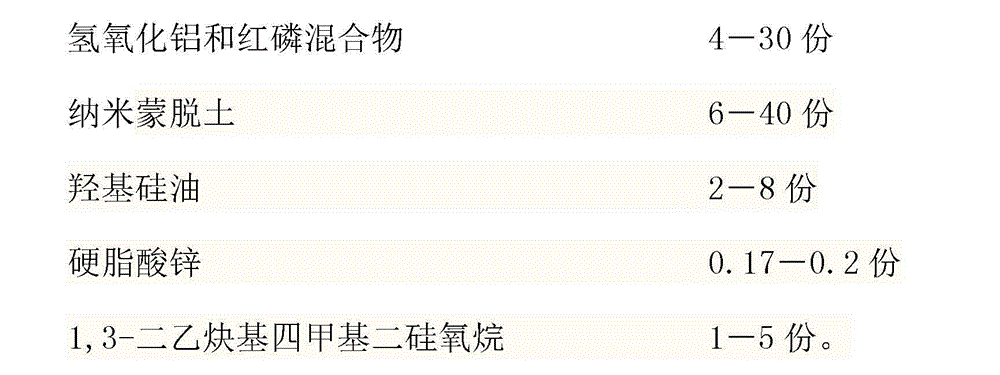

Embodiment 1

[0016] A preparation method of ceramic silicone rubber, the preparation steps are as follows: 100 parts of methyl vinyl silicone rubber raw rubber and 0.17 parts of zinc stearate are kneaded in a vacuum kneader for 3 minutes, and then 20 parts of fumed white carbon black Add 2 parts of hydroxy silicone oil into the vacuum kneader in 3 times, fully stir after each addition, the stirring speed of the active stirring paddle is 62 rpm, and the stirring speed of the driven stirring paddle is 56 rpm, and the mixture Stir and mix evenly, then add 4 parts of the mixture of aluminum hydroxide and red phosphorus, 6 parts of nano-montmorillonite and 1 part of 1,3-diethynyltetramethyldisiloxane, stir well, and wait until the rubber material is kneaded and formed Raise the temperature to 160°C, heat for 90 minutes, then evacuate until the vacuum degree is -0.07MPa, after 30 minutes of vacuuming, the rubber will be released, and the rubber will be passed through the double-roller open rubber...

Embodiment 2

[0018] A preparation method of ceramic silicone rubber, the preparation steps are as follows: 100 parts of methyl vinyl silicone rubber raw rubber and 0.18 parts of zinc stearate are kneaded in a vacuum kneader for 4 minutes, and then 40 parts of precipitated white carbon black Add 6 parts of hydroxy silicone oil into the vacuum kneader in 4 times, fully stir after each addition, the stirring speed of the active stirring paddle is 62 rpm, the stirring speed of the driven stirring paddle is 56 rpm, and the mixture Stir and mix evenly, then add 20 parts of aluminum hydroxide and red phosphorus mixture, 25 parts of nano-montmorillonite and 3 parts of 1,3-diethynyltetramethyldisiloxane, stir well, and wait until the rubber material is kneaded and shaped Raise the temperature to 170°C, heat for 100 minutes, then evacuate to a vacuum degree of -0.06MPa. After evacuating for 50 minutes, the glue is released. The rubber is passed through the double-roller open rubber mixer for 4 times,...

Embodiment 3

[0020] A preparation method of ceramic silicone rubber, the preparation steps are as follows: 100 parts of methyl vinyl silicone rubber raw rubber and 0.2 parts of zinc stearate are kneaded in a vacuum kneader for 5 minutes, and then 60 parts of fumed white carbon black Add 8 parts of hydroxy silicone oil into the vacuum kneader in 5 times, and fully stir after each addition. The stirring speed of the active stirring paddle is 62 rpm, and the stirring speed of the driven stirring paddle is 56 rpm. Stir and mix evenly, then add 30 parts of aluminum hydroxide and red phosphorus mixture, 40 parts of nano-montmorillonite and 5 parts of 1,3-diethynyltetramethyldisiloxane, stir well, and wait until the rubber material is kneaded and shaped Raise the temperature to 180°C, heat for 120 minutes, then evacuate to a vacuum degree of -0.05MPa, and after 60 minutes of vacuuming, the rubber will be released, and the rubber will be passed through the double-roller open rubber mixer for 5 time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com