A kind of high-strength, high-toughness glass fiber reinforced PA/ABS composite material and preparation method thereof

A technology of composite materials and high toughness, applied in the field of composite materials, can solve the problems of reduced strength, tensile strength and bending performance, and achieve the effects of improving fluidity, improving slipperiness and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

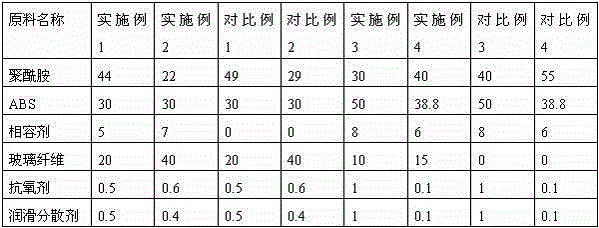

Examples

Embodiment 1~ Embodiment 4

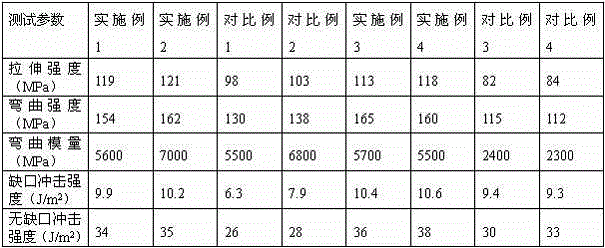

[0023] Embodiment 1~Example 4 and Comparative Example 1~Comparative Example 4

[0024] The polyamide is PA6, the glass fiber is alkali-free glass fiber whose surface has been treated with silane coupling agent, the antioxidant is hindered phenolic antioxidant, the lubricating and dispersing agent is silicone, and the compatibilizer is maleic anhydride, methyl Glycidyl acrylate bifunctional co-grafted polyolefin elastomer. Each raw material was weighed according to the weight percentage shown in Table 1.

[0025] The weight percent (wt%) of each raw material in the table 1 embodiment 1~embodiment 4 and comparative example 1~comparative example 4

[0026]

[0027] Except for the glass fiber, put other raw materials into a high-efficiency mixer and mix for 5 minutes, and then discharge; the obtained premix is extruded and granulated by a twin-screw extruder, and the glass fiber is fed sideways during the extrusion process. The feed port is added, the processing temperatur...

Embodiment 5

[0033] The glass fiber is alkali-free glass fiber whose surface has been treated with silane coupling agent, the antioxidant is hindered phenolic antioxidant, the lubricating and dispersing agent is silicone, the compatibilizer is maleic anhydride, glycidyl methacrylate bis Functional group co-grafted polyolefin elastomer. Take each raw material according to the following weight percentages:

[0034] Polyamide 62.5%, ABS 22%, compatibilizer 5%, glass fiber 10%, antioxidant 0.2%, lubricating dispersant 0.3%.

[0035] Except for glass fiber, put other raw materials into a high-efficiency mixer and mix for 4 minutes, and then discharge; the obtained premix is extruded and granulated by a twin-screw extruder, and the glass fiber is fed sideways during the extrusion process. The feed port is added, the processing temperature is 210-235°C, divided into nine sections, one section is 210°C, the second section is 215°C, the third section is 220°C, the fourth section is 225°C, the fi...

Embodiment 6

[0037] The polyamide is PA6, the glass fiber is alkali-free glass fiber whose surface has been treated with silane coupling agent, the antioxidant is hindered phenolic antioxidant, the lubricating and dispersing agent is silicone, and the compatibilizer is maleic anhydride, methyl Glycidyl acrylate bifunctional co-grafted polyolefin elastomer. Take each raw material according to the following weight percentages:

[0038] Polyamide 39.5%, ABS 22%, compatibilizer 8%, glass fiber 30%, antioxidant 0.3%, lubricating dispersant 0.2%.

[0039] Except for the glass fiber, put other raw materials into the high-efficiency mixer and mix for 3 minutes, and then discharge; the obtained premix is extruded and granulated by a twin-screw extruder, and the glass fiber is fed sideways during the extrusion process. The feed port is added, the processing temperature is 210-235°C, divided into nine sections, one section is 210°C, the second section is 215°C, the third section is 220°C, the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com