Water supply method for blast-furnace slag water treatment and water supply systems

A technology of water supply system and blast furnace slag, which is applied in the field of metallurgical ironmaking equipment, can solve the problems of idle equipment, low utilization rate of cooling tower, and failure of cooling tower equipment level to reach large slag volume operation, etc., and achieve less adding links and environmental protection effect Good, good slag granulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

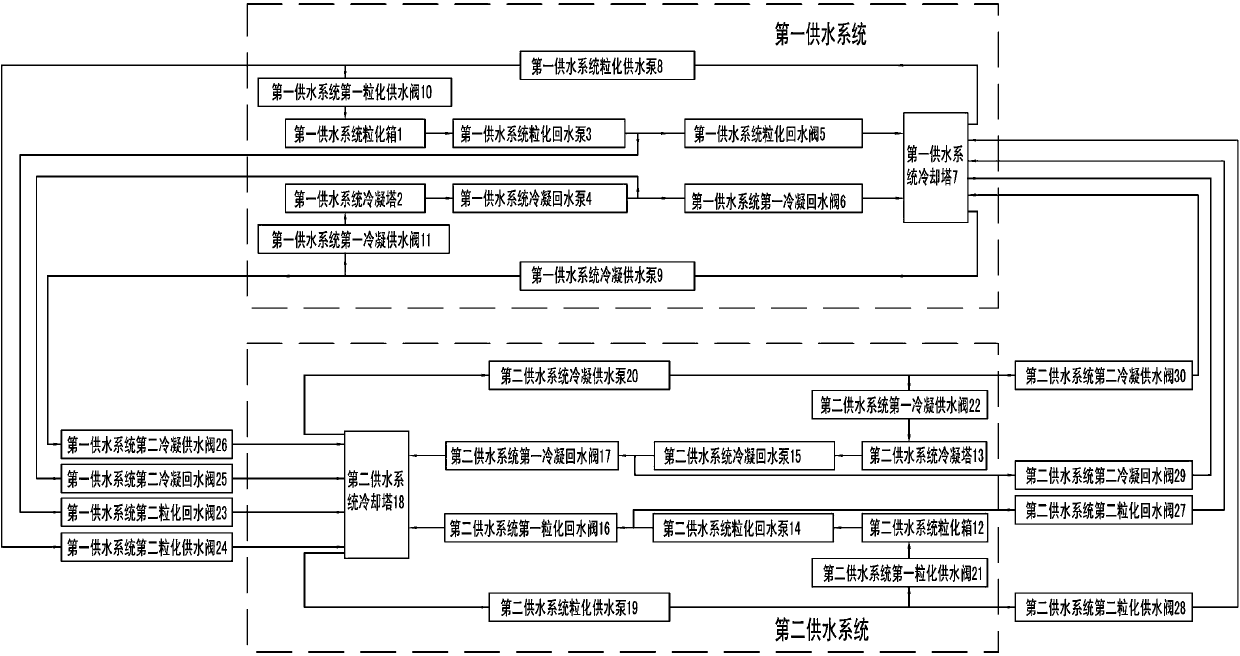

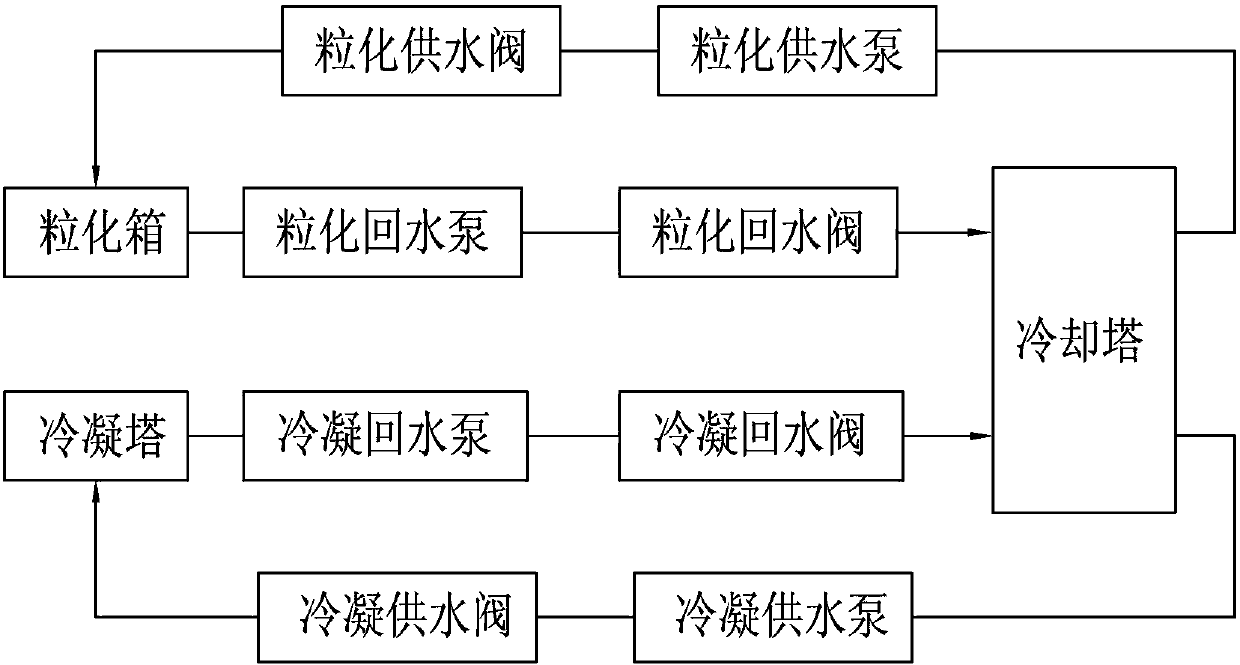

[0025] See attached figure 1 , a water supply system for blast furnace slag water treatment in the present invention includes a first water supply system, wherein the cooling tower 7 of the first water supply system is respectively connected to the granulation tank 1 of the first water supply system and the condensation tower 2 of the first water supply system through pipelines. The first water supply system granulation water supply pump 8, the first water supply system first granulation water supply valve 10, the first water supply system Granulation return pump 3 and the first granulation return valve 5 of the first water supply system; the pipeline between the cooling tower 7 of the first water supply system and the condensation tower 2 of the first water supply system is sequentially provided with the first water supply system condensation The water supply pump 9, the first condensate water supply valve 11 of the first water supply system, the condensate return water pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com