Technology for processing CrNiMo series steel material

A material processing and process technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of walking wheel impact, complex heat treatment process, excessive wear, etc., to improve product service life, process steps Reasonable design to enhance the effect of diffusion capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

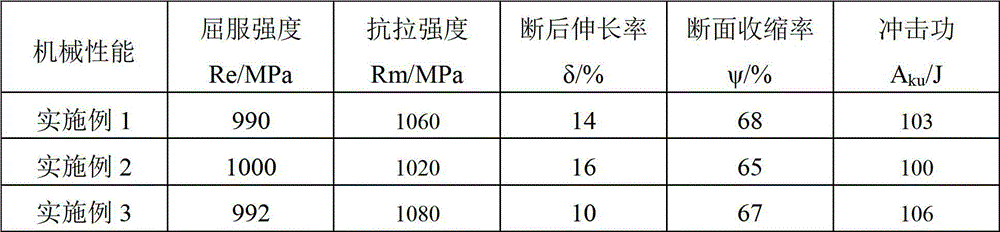

Embodiment 1

[0018] Taking the processing of gears with CrNiMo steel materials as an example, the processing technology includes the following steps:

[0019] Step 1: Using electroslag remelting technology to control the content of alloy elements in steel, in terms of weight percentage, C: 0.14%, Cr: 1.65%, Si: 0.17%, Mn: 0.4%, Mo: 0.36%, Ni: 1.6 %, P: 0.035%, S: 0.030% to obtain steel ingots, control the mixing of other metal impurities and gases during the smelting process to ensure the purity of raw materials, and then forge the steel ingots;

[0020] Step 2: In order to eliminate the stress generated by forging, pre-heat treatment process is carried out on the workpiece. The pre-heat treatment process includes normalizing process and high temperature tempering process. The normalizing process is to heat the workpiece to 600 ° C for 3.5 hours and then heat it to 890 ° C Air cooling after 6 hours of heat preservation, because this series of steel contains high Cr, Ni, and Mo elements, it...

Embodiment 2

[0025] Taking the processing of gears with CrNiMo steel materials as an example, the processing technology includes the following steps:

[0026] Step 1: Using electroslag remelting technology to control the content of alloy elements in steel, in terms of weight percentage, C: 0.19%, Cr: 1.5%, Si: 0.24%, Mn: 0.48%, Mo: 0.25%, Ni: 1.7 %, P: 0.022%, S: 0.017% to obtain steel ingots, control the mixing of other metal impurities and gases during the smelting process to ensure the purity of raw materials, and then forge the steel ingots;

[0027] Step 2: In order to eliminate the stress generated by forging, pre-heat treatment process is carried out on the workpiece. The pre-heat treatment process includes normalizing process and high temperature tempering process. The normalizing process is to heat the workpiece to 660°C for 2 hours and then heat it to 950°C Air cooling after 10 hours of heat preservation, because this series of steel contains high Cr, Ni, and Mo elements, it play...

Embodiment 3

[0032] Taking the processing of gears with CrNiMo steel materials as an example, the processing technology includes the following steps:

[0033] Step 1: Using electroslag remelting technology to control the content of alloy elements in steel, in terms of weight percentage, C: 0.16%, Cr: 1.8%, Si: 0.35%, Mn: 0.6%, Mo: 0.3%, Ni: 1.4 %, P: 0.005%, S: 0.005% to obtain steel ingots, control the mixing of other metal impurities and gases during the smelting process to ensure the purity of raw materials, and then forge the steel ingots;

[0034]Step 2: In order to eliminate the stress caused by forging, pre-heat treatment process is carried out on the workpiece. The pre-heat treatment process includes normalizing process and high temperature tempering process. The normalizing process is to heat the workpiece to 700 ° C for 6 hours and then heat it to 915 ° C Air cooling after heat preservation for 3 hours, because this series of steel contains high Cr, Ni, Mo elements, it plays a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com