Continuous production process of high temperature resistant glassiber cloth

A technology of glass fiber cloth and production process, which is applied in fiber treatment, dry-cleaning fiber products, textiles and papermaking, etc. It can solve the problems of poor product quality stability, difficulty in achieving large-scale stable production, poor mechanical properties of products, etc., and achieve product quality Stable, good economic benefits, good physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

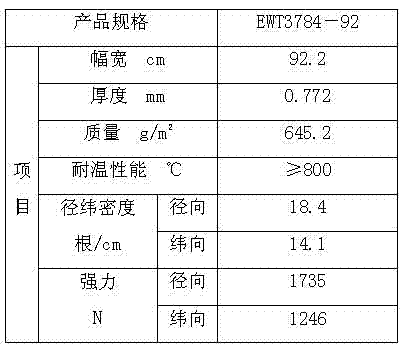

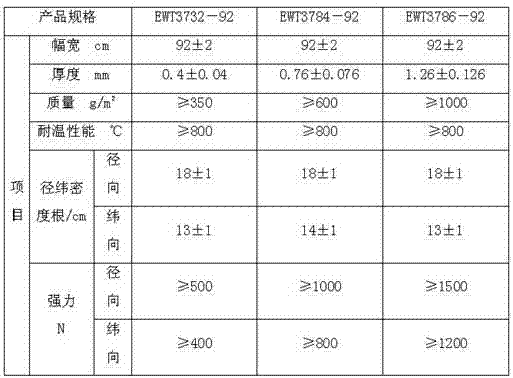

[0023] Implementation example 1: Production of EWT3784-92 high temperature resistant glass fiber cloth:

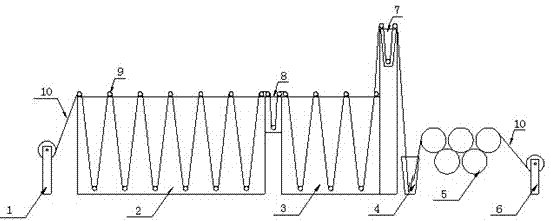

[0024] (1) Put a roll of 400-meter EW3784-92 non-alkali glass fiber gray cloth on the gray cloth frame 1, then put the cloth along the acid leaching tank 2 guide roller 9, transfer tank 8 guide roller 9, wash with water Cloth guide roller 9 in slot 3 and cloth guide roller 9 in high position cloth guide slot 7 enter temporary cloth storage tank 4, and then wind up to product cloth winding equipment 6 through drying equipment 5.

[0025] (2) Add 1.7N hydrochloric acid solution to the acid leaching tank 2, the liquid level is 8-12 cm from the upper edge of the acid leaching tank; add water to the transfer tank 8, and the liquid level is 13 cm from the upper edge of the transfer tank ~17cm; add water to the washing tank 3, the liquid level is 8-12cm away from the upper edge of the washing tank; add it to the high-level cloth guide groove 7, and the water level is 13-17cm away...

Embodiment 2

[0033] Implementation example two: production of EWT3786-92 high temperature resistant glass fiber cloth:

[0034] (1) Put a roll of 400-meter EW3786-92 non-alkali glass fiber gray cloth on the gray cloth frame 1, and then put the cloth along the acid leaching tank 2 guide roller 9, transfer tank 8 guide roller 9, wash with water Cloth guide roller 9 in slot 3 and cloth guide roller 9 in high position cloth guide slot 7 enter temporary cloth storage tank 4, and then wind up to product cloth winding equipment 6 through drying equipment 5.

[0035] (2) Add 1.9N hydrochloric acid solution to the acid leaching tank 2, the liquid level is 8-12 cm from the upper edge of the acid leaching tank; add water to the transfer tank 8, and the liquid level is 13 cm from the upper edge of the transfer tank ~17cm; add water to the washing tank 3, and the liquid level is 8-12 cm from the upper edge of the washing tank; add water to the high-level cloth guide groove 7, and the liquid level is 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com