Cigarette paper burning regulating agent capable of reducing perniciousness coefficient of cigarettes and application of cigarette paper burning regulating agent

A technology of combustion regulator and hazard index, applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problems of negative impact on the sensory quality of cigarettes, large increase in delivery volume, etc., achieve good industrial application value, and the process is easy to control , The effect of low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

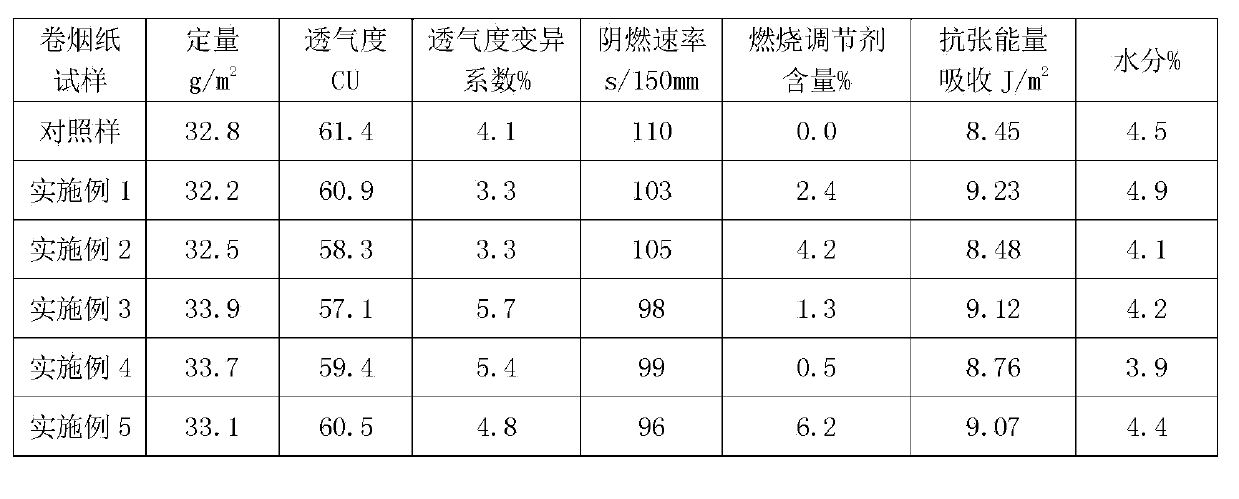

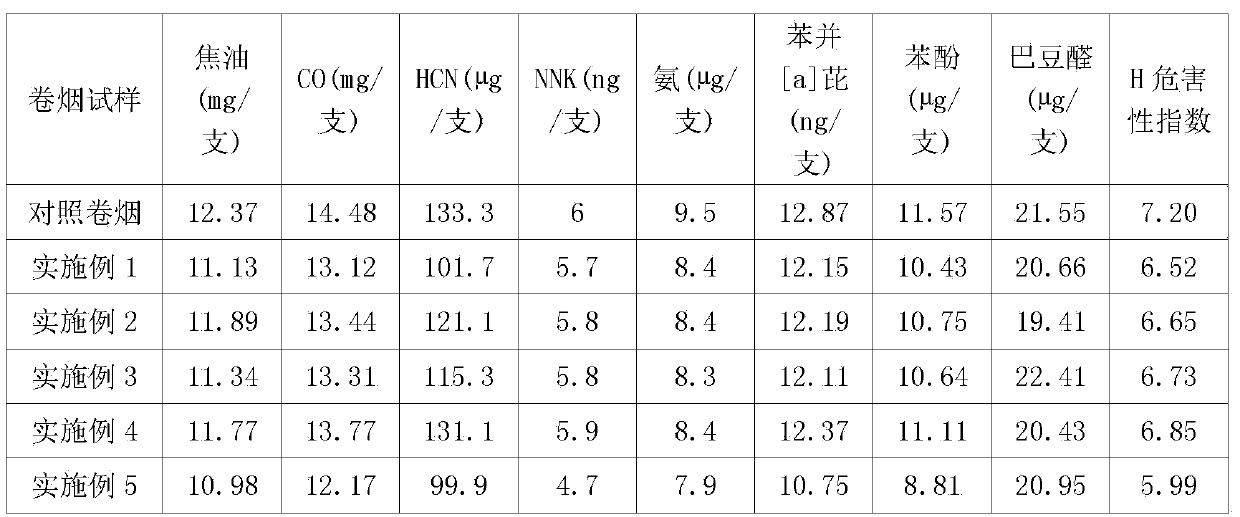

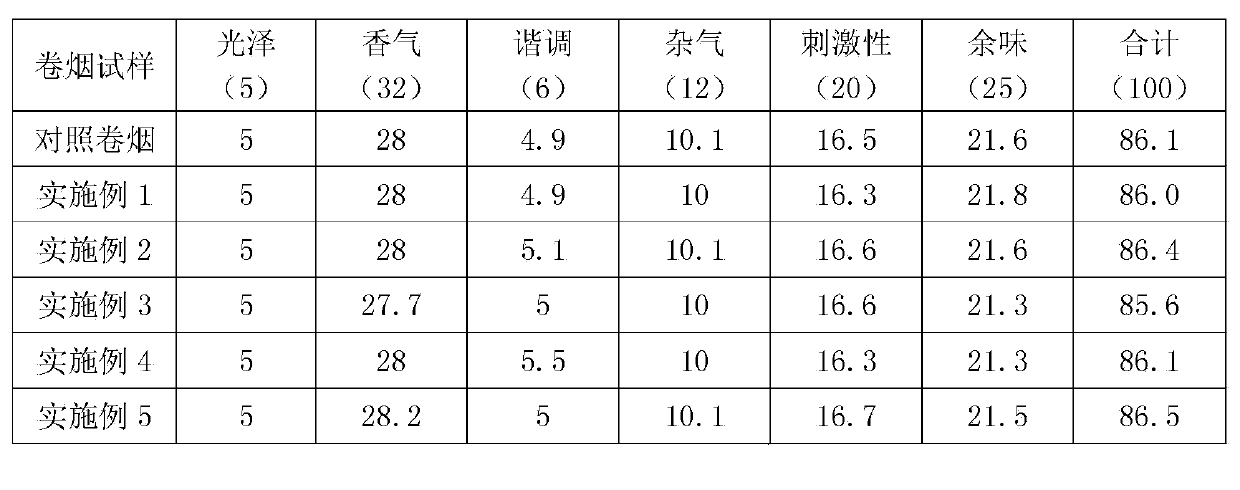

[0022] Dissolve 85 parts of potassium phytate and 25 parts of gluconolactone in 400 parts of water, stir well, and measure the pH value of the solution to be 7.8. The concentration of potassium phytate contained in the combustion regulator suspension was 16.7%, and the concentration of gluconolactone was 4.9%. The prepared combustion regulator suspension was evenly added to the cigarette paper in the sizing section of cigarette paper production through a metering rod film transfer sizing machine, and the production process and paper machine equipment parameters were adjusted to obtain the physical indicators of the cigarette paper shown in the table 1. The prepared functional cigarette paper and ordinary cigarette paper were used in the production of a certain brand of Sichuan-Chongqing China Tobacco cigarettes, and the rolled cigarettes were analyzed for seven harmful components in mainstream smoke, cigarette hazard index analysis and sensory quality evaluation. Taking ordin...

Embodiment 2

[0024] Dissolve 50 parts of potassium phytate, 25 parts of sodium phytate, 5 parts of gluconolactone, and 10 parts of potassium bicarbonate in 400 parts of water, stir well until the reaction between gluconolactone and potassium bicarbonate is completed, and measure the pH of the solution The value is 8.3. The concentrations of the components contained in the combustion regulator suspension are: potassium phytate 10.2%, sodium phytate 5.1%, potassium gluconate 1.3%, and potassium bicarbonate 1.5%. The prepared combustion regulator suspension was evenly added to the cigarette paper in the sizing section of cigarette paper production through a metering rod film transfer sizing machine, and the production process and paper machine equipment parameters were adjusted to obtain the physical indicators of the cigarette paper shown in the table 1. The prepared functional cigarette paper and ordinary cigarette paper were used in the production of a certain brand of Sichuan-Chongqing C...

Embodiment 3

[0026] Dissolve 85 parts of sodium phytate and 20 parts of gluconolactone in 400 parts of water, stir well, and measure the pH value of the solution to be 6.7. The concentration of sodium phytate contained in the combustion regulator suspension was 16.8%, and the concentration of gluconolactone was 4%. The prepared suspension of the combustion regulator was evenly transferred to the cigarette paper through the plate roller of the gravure printing machine, and the physical indicators of the prepared cigarette paper are shown in Table 1. The prepared functional cigarette paper and ordinary cigarette paper were used in the production of a certain brand of Sichuan-Chongqing China Tobacco cigarettes, and the rolled cigarettes were analyzed for seven harmful components in mainstream smoke, cigarette hazard index analysis and sensory quality evaluation. Taking ordinary cigarette paper as the control sample, the results are shown in Table 2 and Table 3 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com