A kind of papermaking method tobacco sheet preparation method and its finished product

A technology of tobacco sheet and paper making method, applied in the field of tobacco industry, can solve the problems of residue, cigarette woody taste and oral irritation, and achieve the effects of increasing the ash content of paper base, improving the physical properties and increasing the speed of the paper machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

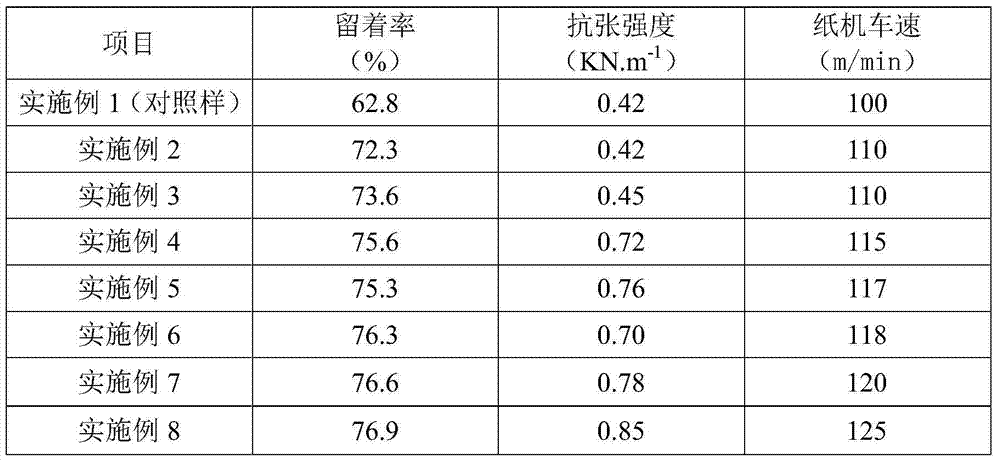

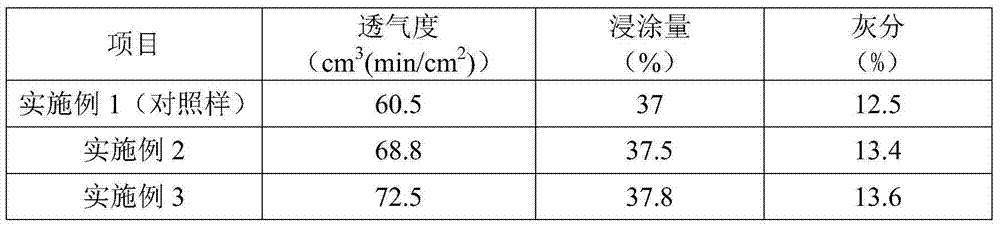

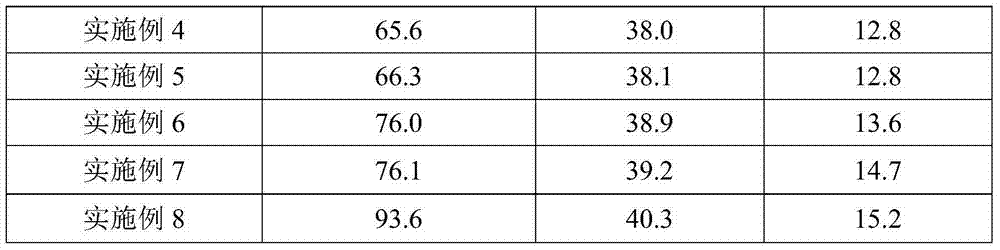

Examples

Embodiment 1

[0022] Example 1: Using conventional methods to prepare paper-making tobacco sheets

[0023] 1) Extraction and concentration of effective ingredients in tobacco:

[0024] Tobacco stem raw materials and tobacco dust raw materials feed ratio is 6:4; the extraction conditions of tobacco stalk raw materials solubles are as follows: material-to-liquid ratio 1:6, temperature 60 degrees, soaking time 40 minutes; extraction conditions for soluble tobacco dust raw materials: The ratio of material to liquid is 1:12, the temperature is 60 degrees, and the soaking time is 30 minutes. Separate the extracts of tobacco stalks and tobacco powder through horizontal spiral unloading sedimentation centrifuge and disc separator to achieve solid-liquid separation, and then respectively enter the concentration system for concentration, and the mixed extract concentrates are extracted according to the tobacco stalks. The extraction concentrate is mixed at a ratio of 1:1.

[0025] 2) Pulp and papermaking:...

Embodiment 2

[0030] Example 2: Filler research experiment

[0031] The difference from Example 1 is that in the 8% filler, calcium carbonate accounts for 60%, and diatomaceous earth accounts for 40%.

Embodiment 3

[0032] Example 3: Filler research experiment

[0033] The difference from Example 1 is that in the 8% filler, calcium carbonate accounts for 40%, diatomaceous earth accounts for 40%, and sepiolite 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com