Cigarette paper burning conditioning agent for reducing harm and improving quality and application of cigarette paper burning conditioning agent

A combustion regulator, cigarette paper technology, applied in papermaking, textiles and papermaking, non-fibrous pulp addition, etc., can solve the problems of large increase in delivery volume, negative impact on cigarette sensory quality, etc., achieve simple preparation process and reduce cigarette hazards Performance index, good industrial application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Slowly add 1948 parts of water into 168 parts of potassium hydroxide, start stirring, slowly add 174 parts of aconitic acid into the aqueous potassium hydroxide solution after dissolving, continue to stir for 20min, and mix 168 parts of gulonic acid after the reaction is completed The lactone was added to the reaction system, kept stirring, and left to stand for 2 hours after completely dissolving. The concentration of potassium aconitate in the generated combustion regulator suspension was 10.3%, and the concentration of gulonolactone was 6%. The pH of the aqueous solution was measured The value is 6.97.

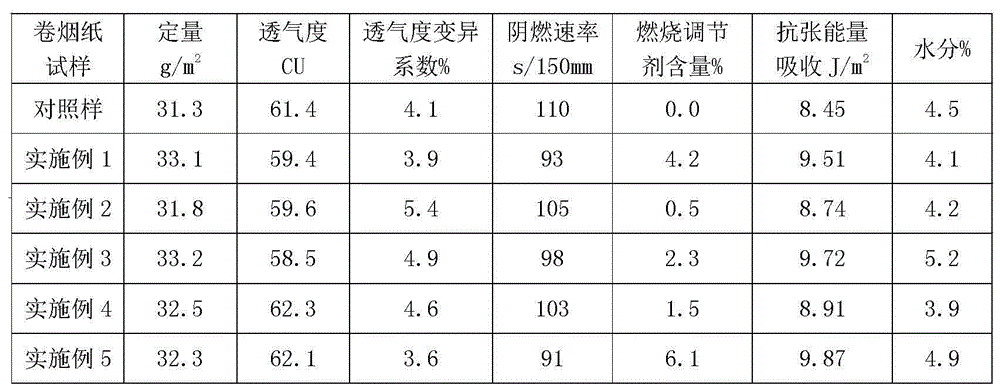

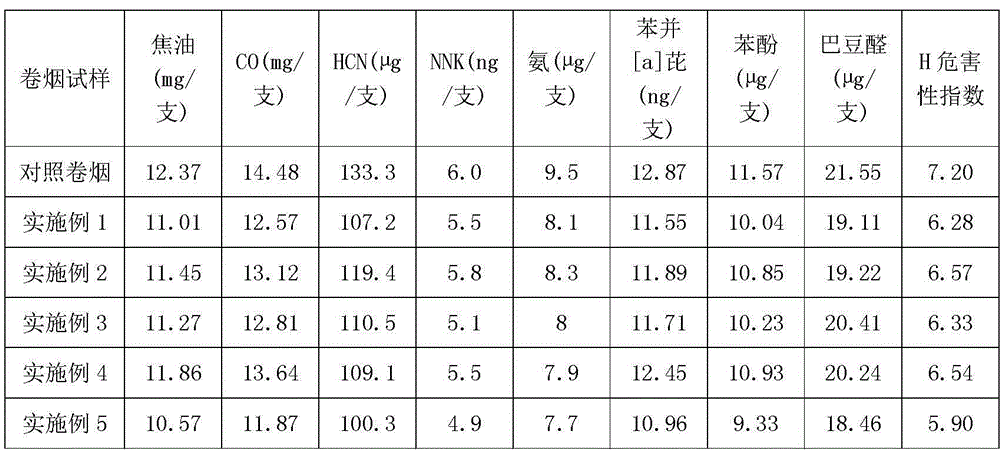

[0027] The prepared combustion regulator suspension was evenly added to the cigarette paper in the sizing section of cigarette paper production through a metering rod film transfer sizing machine, and the production process and paper machine equipment parameters were adjusted to obtain a cigarette paper with a weight of 31.3g / m 2 , the air permeability is 61.4CU, a...

Embodiment 2

[0029] Dilute the combustion regulator aqueous solution in Example 1 by 1 time, that is, the concentration of potassium aconitate is 5.2%, and the concentration of gulonolactone is 3%. Repeat the above production process and analysis test. The results are shown in Table 1~ table 3.

Embodiment 3

[0031] Weigh 178 parts of gulonolactone and add it to 1646 parts of water, stir evenly, let it stand for 2 hours, slowly add 100 parts of potassium bicarbonate to the gulonolactone solution, keep stirring, control the adding speed so as not to make bubbles Overflow the reaction vessel, after reacting for 0.5 hours, add 40 parts of guluronic acid lactone to the reaction system and keep stirring for 0.5 hours. The concentration of potassium guluronic acid in the generated combustion regulator suspension is 11.7%, and the content of guluronic acid The ester concentration is 2%, and the measured pH value of the aqueous solution is 7.12. Using the prepared combustion regulator suspension, repeat the above production process and analysis test, the results are shown in Tables 1 to 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com