A kind of citrus peel filter rod porous material and its preparation method and application

A technology of porous materials and citrus peels, which is applied in the field of porous materials, can solve problems such as difficulty in retaining the fresh aroma of citrus peels, breakthroughs in the hazard index of cigarettes, shrinkage and hardening of citrus peel tissues, and reduce the hazard index of cigarettes, increase strength and Porous structure stability, effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

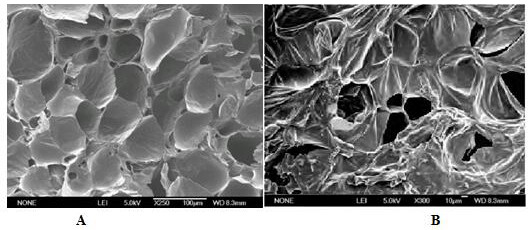

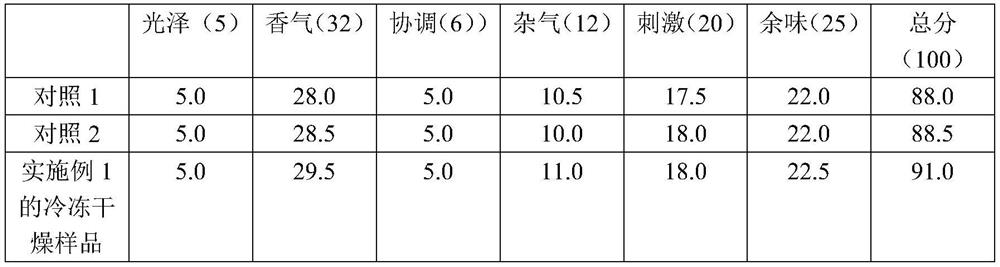

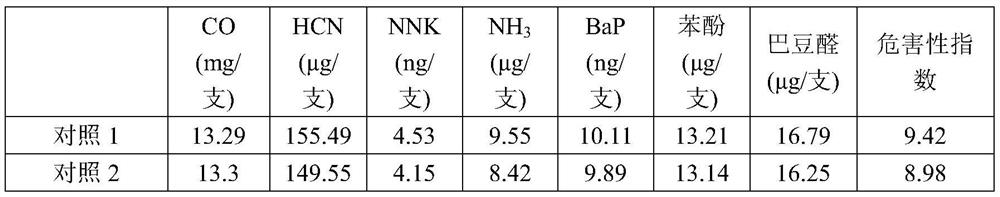

[0035] The preparation method of the citrus peel filter rod porous material of the present embodiment is carried out as follows:

[0036] Take fresh sweet orange peel, wash it thoroughly, and cut it into small pieces of 2-3cm square.

[0037] Put the sweet orange peel pieces into the 90°C strengthening solution at a constant temperature for 3 minutes at a ratio of 1:1. The concentration of sucrose in the strengthening solution is 25%, the concentration of mannitol is 5%, the concentration of gelatin is 3%, carboxymethyl The concentration of cellulose was 1.2%.

[0038] After draining the water, freeze at -60°C for 4 hours; vacuum-dry the pre-frozen sample at a vacuum degree of 86Pa, sublimation heating temperature of 42°C, and analytical heating temperature of 75°C to obtain a freeze-dried product with a moisture content of 5%. Sweet orange peel material.

[0039] The sweet orange peel material is crushed to 18 mesh to 30 mesh to obtain the porous material of the orange peel...

Embodiment 2

[0052] The preparation method of the citrus peel filter rod porous material of the present embodiment is carried out as follows:

[0053] Take fresh lemon peel, wash it thoroughly, and cut it into small pieces of 2-3cm square.

[0054] Put the lemon peel into the 90°C strengthening solution at a constant temperature and soak for 3 minutes at a ratio of 1:1. The concentration of sucrose in the strengthening solution is 25%, the concentration of mannitol is 5%, the concentration of gelatin is 3%, carboxymethyl fiber The concentration of the element is 1.2%.

[0055] After draining the water, freeze at -60°C for 4 hours; vacuum-dry the pre-frozen sample at a vacuum degree of 80Pa, sublimation heating temperature of 47°C, and analytical heating temperature of 70°C to obtain a freeze-dried product with a moisture content of 5%. Lemon peel material.

[0056] The lemon peel material is crushed to 18-30 mesh to obtain the porous material of the citrus peel filter rod.

[0057] Observ...

Embodiment 3

[0068] The preparation method of the citrus peel filter rod porous material of the present embodiment is carried out as follows:

[0069] Take fresh grapefruit peels and lemon peels, wash them thoroughly, and cut them into small pieces of 2-3cm square, the mass fraction ratio of the two is 1:1.

[0070] Put the mixed pericarp into 90°C strengthening solution at a constant temperature for 3 minutes at a ratio of 1:1. The concentration of sucrose in the strengthening solution is 25%, the concentration of mannitol is 5%, the concentration of gelatin is 3%, carboxymethylcellulose The concentration is 1.2%.

[0071] After draining the water, freeze at -60°C for 4 hours; vacuum-dry the pre-frozen sample at a vacuum degree of 80Pa, sublimation heating temperature of 47°C, and analytical heating temperature of 70°C to obtain a freeze-dried product with a moisture content of 5%. Citrus peel material.

[0072] The mixed citrus peel material is crushed to 18-30 mesh to obtain a porous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com