Construction method for coating rafters of pseudo-classic architecture roof by using aluminum veneers

A construction method and technology of imitating ancient buildings, applied in the processing of building materials, construction, building construction, etc., can solve problems such as complicated procedures, poor durability, easy corrosion and damp maintenance costs, etc., to avoid environmental pollution, improve efficiency, and make up for The effect of time deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

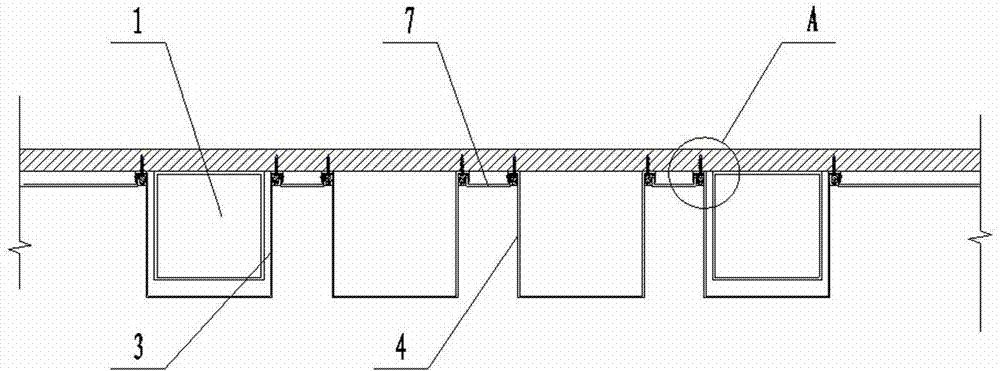

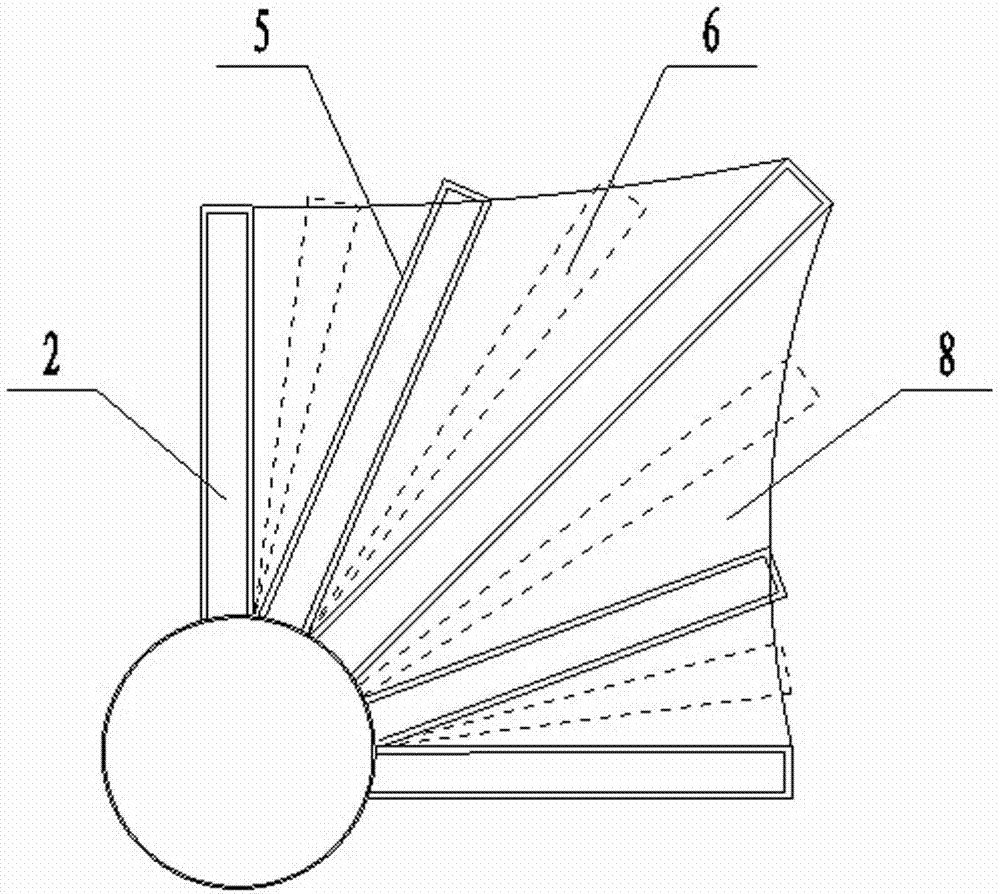

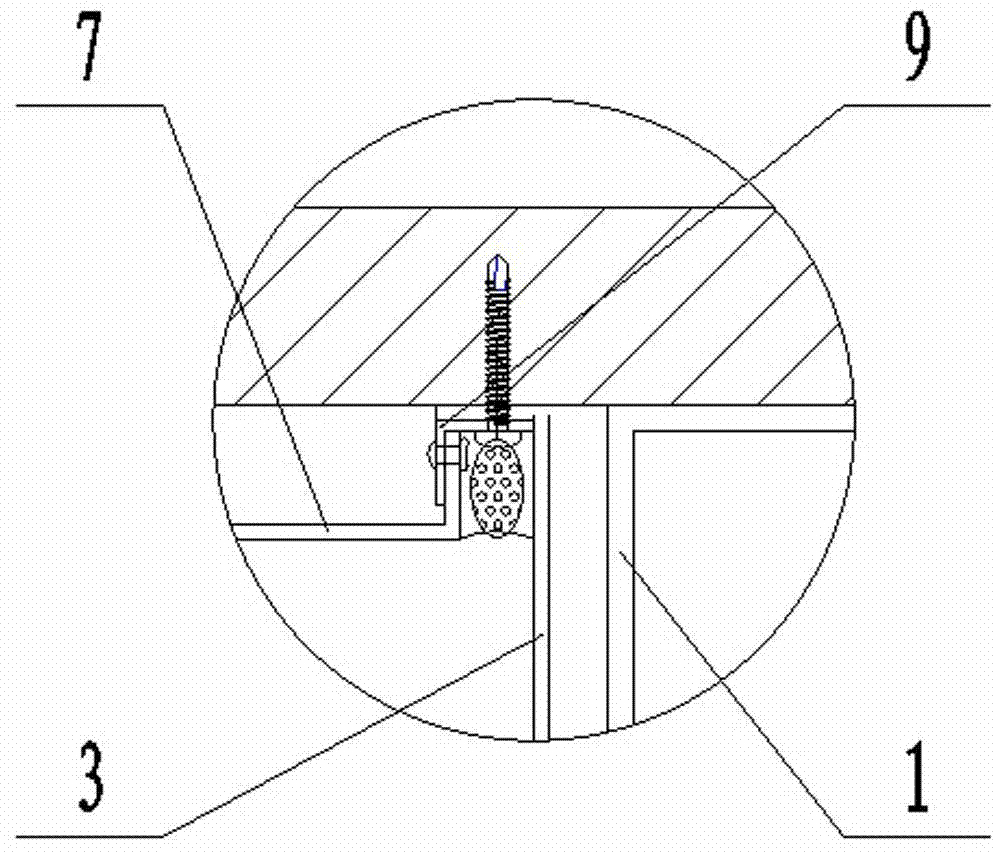

[0011] The construction method of the aluminum veneer rafter-clad archaic building roof adopts the following steps: a. Retest the installed steel body rafter 1, steel wing corner rafter 2 and rafter spacing, and make overall adjustment and equal distribution according to the actual measurement results, Use AUTOCAD typesetting for secondary design, and block numbering, and draw aluminum veneer processing drawings; b. After cutting, folding, bending, welding, and grinding, the aluminum veneer is processed and shaped, and sprayed with fluorocarbon topcoat; c. 1. The steel body rafter 1 and the steel wing corner rafter 2 are respectively covered with an aluminum veneer cover 3 and a wing angle aluminum veneer cover 5 matching their shapes, and two aluminum veneer covers 3 are evenly arranged between the two aluminum veneer covers 3 and are located under the wooden base. The hollow aluminum veneer cover 4 on the side, and a wing angle hollow aluminum veneer cover 6 located at the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com