Method and device for improving pore-forming efficiency of rotary drilling rig

A technology for rotary drilling rigs and digging rigs, which is applied to drilling equipment and methods, rotary drilling rigs, rotary drilling, etc., to achieve the effects of improving hole forming efficiency and ensuring mechanical construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

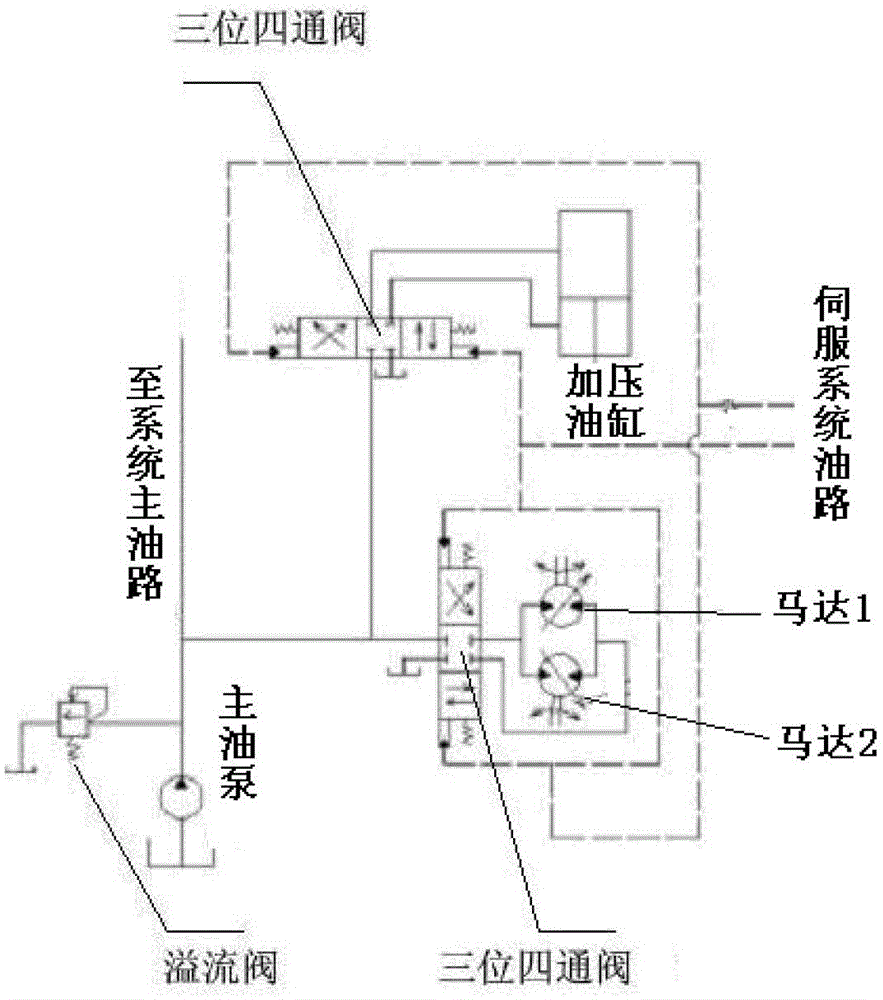

Method used

Image

Examples

Embodiment 1

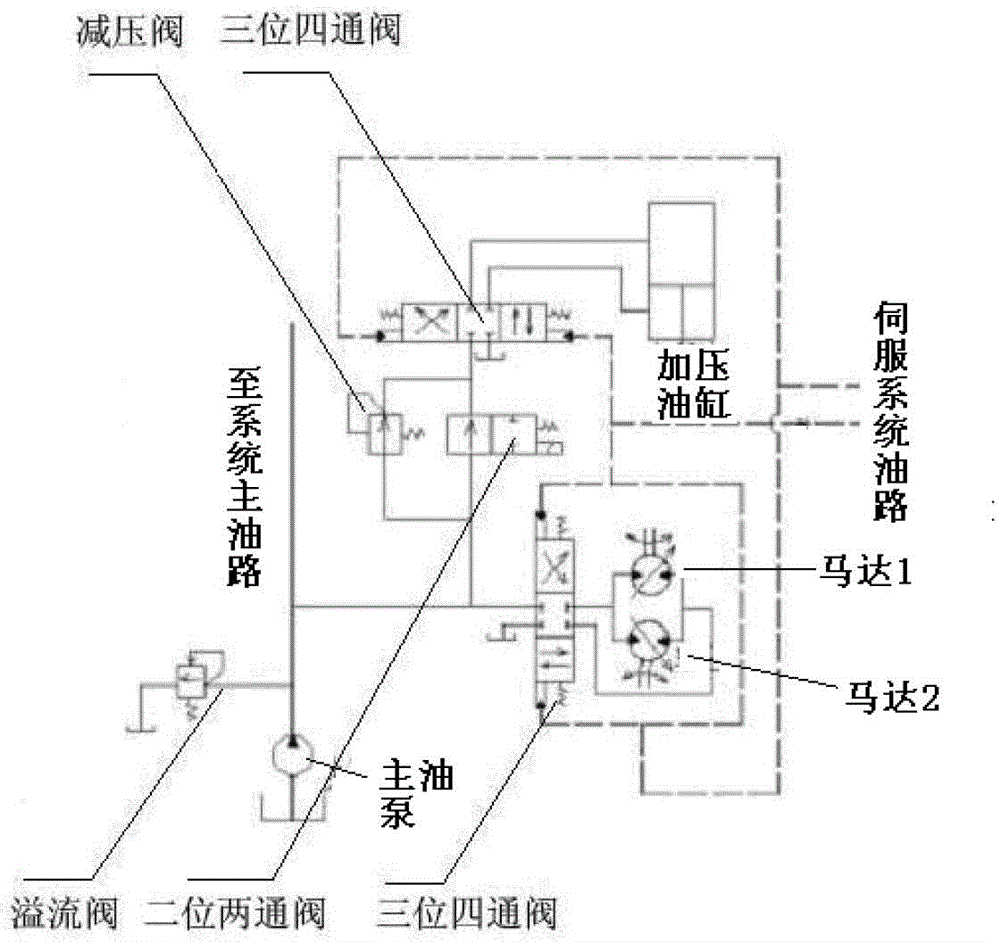

[0031] see figure 2 , A pressure reducing valve and a two-position two-way (electromagnetic) valve are added to the oil circuit system to adjust the pressure of the relief valve, and the pressure-reducing valve is connected in parallel with the two-position two-way valve. The two-position two-way valve changes the on-off relationship between the pipelines by changing the position of the spool in the valve body; when used in parallel with the pressure reducing valve, when the pressure of the main oil circuit reaches 25Mpa, the two-position two-way valve closes, Pressure reducing valve through oil. The model of the two-position two-way valve is K23TK-20, the standard aperture is Φ20, the flow rate is 110~120L / min, and the operating pressure is 0.2~0.8 MPa; the model specification of the pressure reducing valve: PR(C)V-G / T20, the maximum pressure is 25MPa; The pressure adjustment range is 1~10MPa; the flow rate is 90-120L / min. Set the pressure reducing valve to 8Mpa and contro...

Embodiment 2

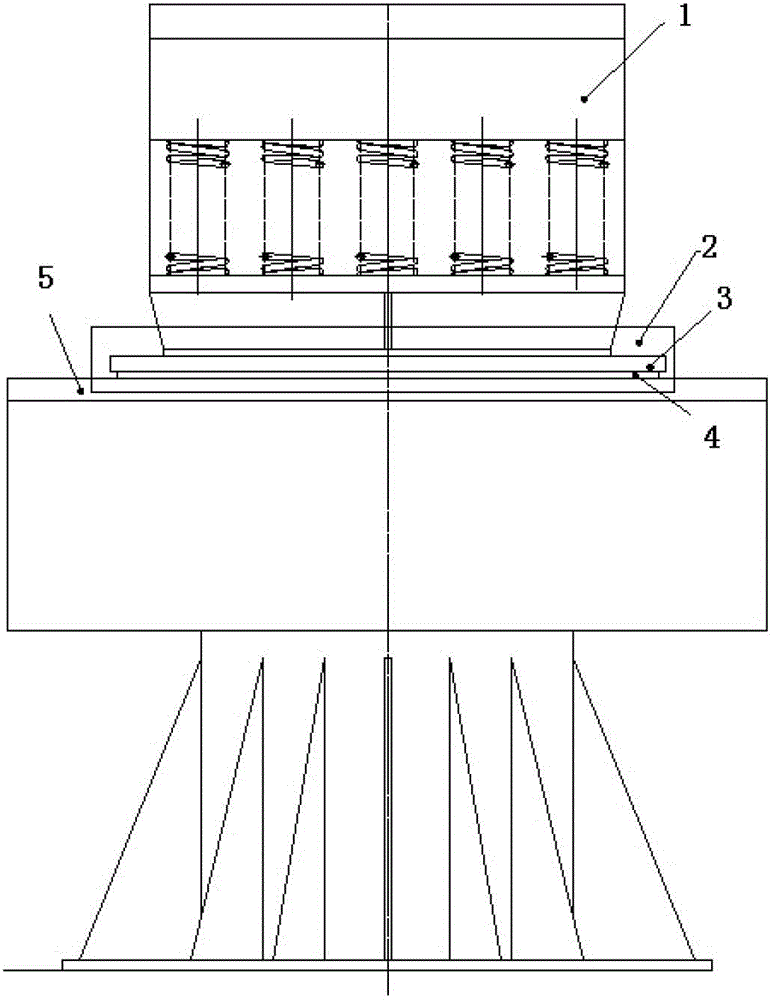

[0035] The present invention designs a power head anti-mudwater sealing protection device, see the attached image 3 , the protection device includes a shock absorber 1, a mudwater infiltration prevention device 2, and a power head cover 5, wherein the mudwater infiltration prevention power head device 2 includes a mud-proof cover 3 and a sealing ring 4.

[0036] Because the muddy water infiltration device 2 is mainly used for waterproofing, the mud-proof cover 3 is to select a thickness of 23mm and the outer diameter is φ836mm, and the inner diameter is φ500mm steel plate to be processed into an annular ring, and 24 circles with a diameter of φ20mm are drilled on the circumference of φ600mm. Hole 6 can connect the mud shield 3 and the lower power system body through the round hole 6, and squeeze the sealing ring 4; according to the width of the sealing ring 4, the outer diameter of the annular ring is processed to be 1120mm, the inner diameter is φ700mm, and the depth is 10mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com