High-sensitivity strip drift detection device based on array infrared technology

A high-sensitivity, infrared technology, applied in the field of automatic control, can solve problems such as low stability, low sensitivity, and small measurement range, and achieve the effects of simple and easy installation, improved measurement resolution, and simple and intuitive calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples, but these examples should not be construed as limiting the present invention.

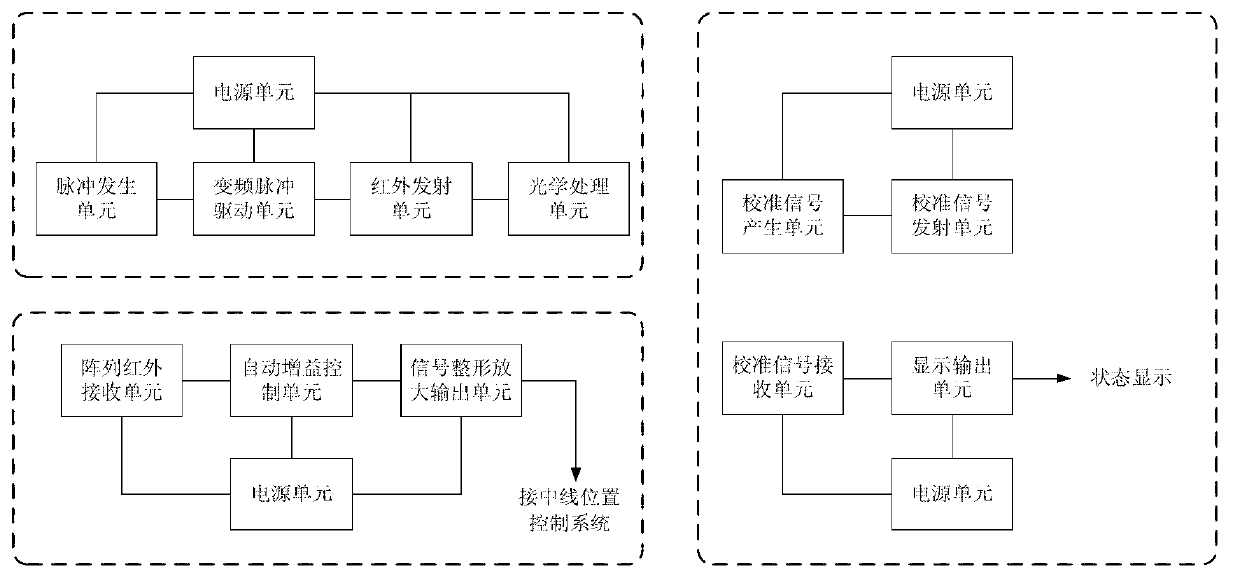

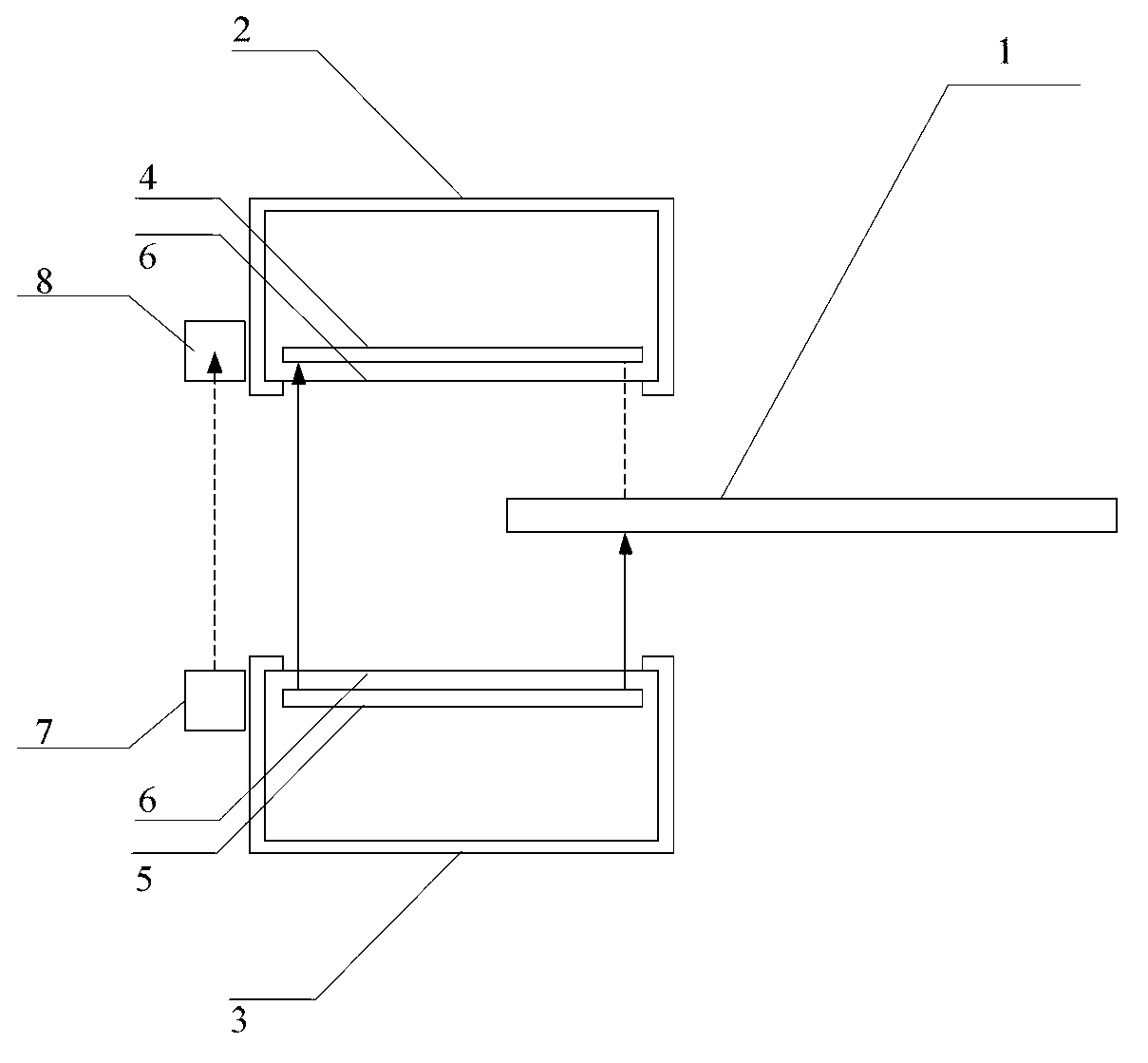

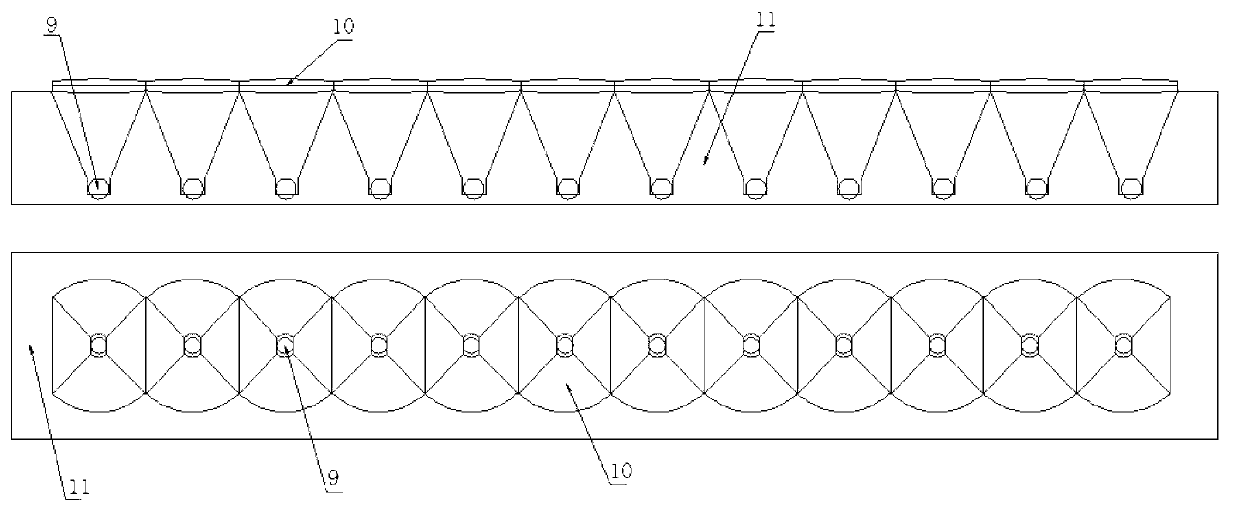

[0027] Depend on figure 1 It can be seen that the present invention includes three components: an infrared emitting device, an infrared receiving device and an auxiliary calibration device. Depend on figure 2It can be seen that the auxiliary calibration device in the embodiment of the present invention includes two parts: an infrared calibration signal transmitting module 7 and an infrared calibration signal receiving module 8, wherein the infrared calibration transmitting unit 7 of the auxiliary calibration device is on the same physical level as the infrared emitting device 3, The infrared calibration receiving unit 8 of the auxiliary calibration device and the infrared receiving device 2 are also located on the same physical device level. The interrelationships an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com