Hot-dipping aluminum-zinc alloy coated steel plate coating structure display method

A technology of hot-dip aluminum coating and display method, which is applied in the preparation of test samples, etc., can solve the problems that the coating performance of this type of steel plate cannot be predicted in advance, and the display and identification of the coating structure cannot be carried out, so as to achieve a clear and good display effect. The effect of low cost and easy procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

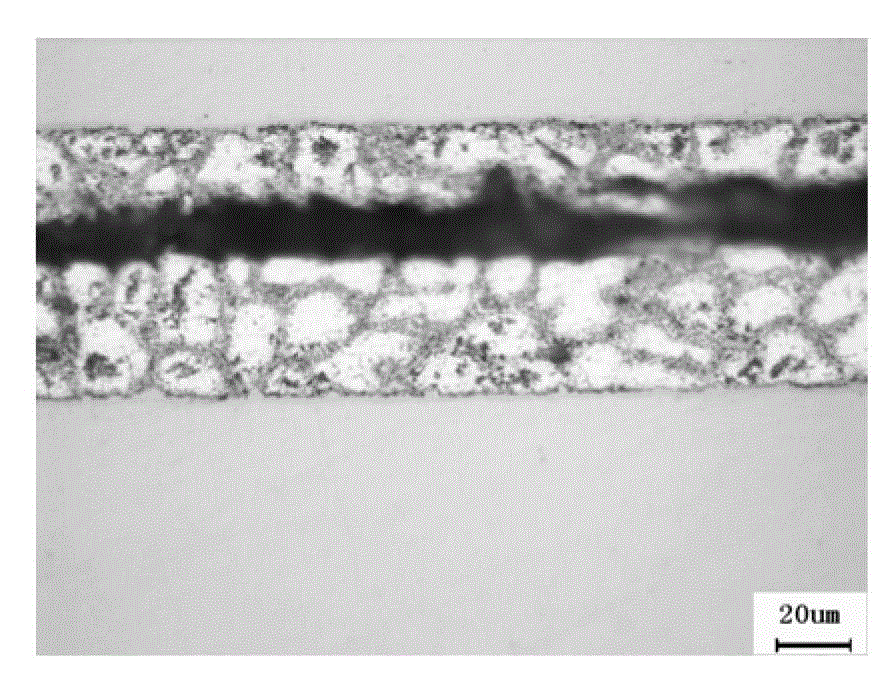

[0035] The selected sample is 150g / m 2 Specification of 55% Al-Zn hot-dip galvalume steel sheet sample for coating structure display. The production process of the selected sample is briefly described as follows: the composition of the plating solution is 55%Al-43.3%Zn-1.4%Si, the temperature of the plating solution is 590-610°C, the steel strip enters the plating pot through the furnace nose for immersion plating, the steel strip The temperature of entering the pot is about 610-630°C. After bypassing the sinking roller, it exits the plating pot. After passing through the stabilizing roller, it is cooled rapidly by an air knife.

[0036] Plating structure display is carried out according to the following steps:

[0037] 1. After smearing vaseline on the surface of the hot-dip galvanized steel plate to be inspected, cut a metallographic sample of 20mm×15mm by wire cutting.

[0038] 2. After clamping or inlaying the sample, grind it in the order of 180#, 400#, 800#, and 1200# ...

example 2

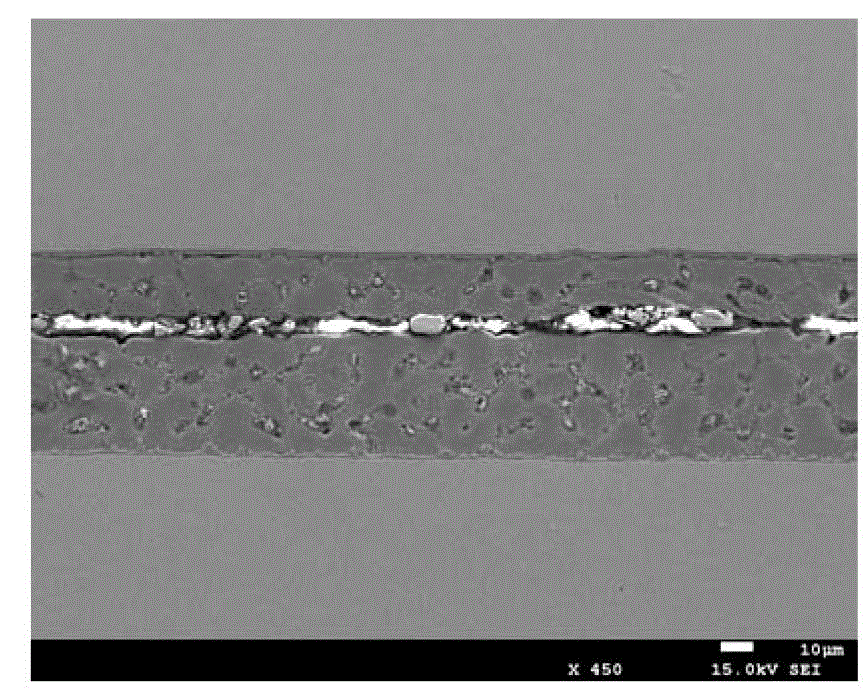

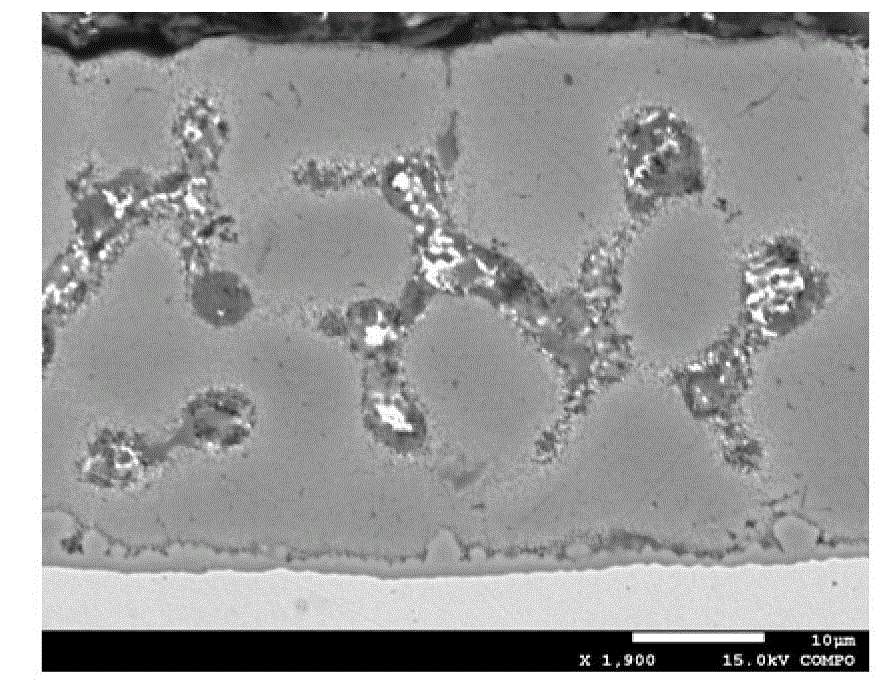

[0049] The selected sample is 180g / m 2 Specification of 55% Al-Zn hot-dip galvalume steel sheet sample for coating structure display. The production process of the selected sample is briefly described as follows: the composition of the plating solution is 55%Al-44.1%Zn-0.8%Si-0.05%RE (rare earth), the temperature of the plating solution is 580-600°C, and the steel strip enters the plating layer through the furnace nose. The pot is dip-coated. The temperature of the steel strip entering the pot is about 630-650°C. After bypassing the sinking roller, it exits the plating pot. After passing through the stabilizing roller, it is cooled rapidly by an air knife.

[0050] Plating structure display is carried out according to the following steps:

[0051] 1. After smearing vaseline on the surface of the hot-dip galvanized steel plate to be inspected, cut a metallographic sample of 20mm×15mm by wire cutting.

[0052] 2. After clamping or inlaying the sample, grind it in the order of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com