High-throughput automatic corrosion resistance evaluation device capable of achieving in-situ measurement

An in-situ measurement and evaluation device technology, which is applied in the direction of measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as in-situ synchronous measurement, accurate and efficient research on corrosion behavior obstacles, etc., and achieve convenient replacement and procurement , easy to purchase, and reduce labor time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

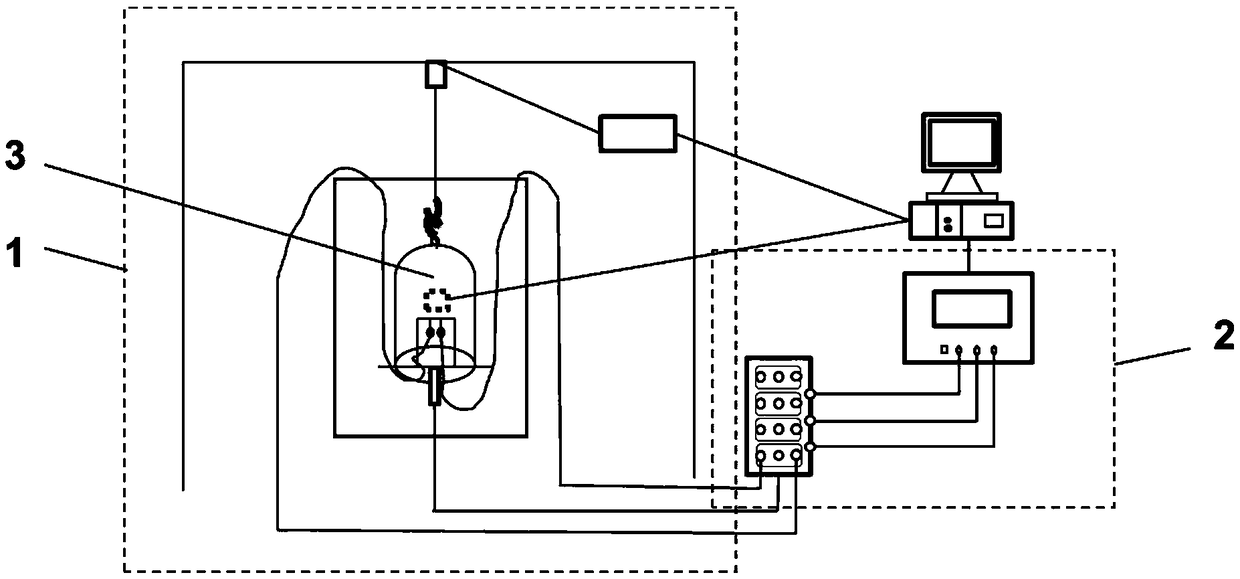

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0036] The high-throughput automated hydrogen collection device is divided into two structures

[0037] The first structure is a liquid discharge weighing structure, such as Figure 4 ; The sample is sealed (21) with epoxy resin, and a working surface is reserved for the sealed sample, and the back is punched and tapped, such as Figure 6 Rotate and compress with the sealing ring (20) to ensure that there is no water between the wire (17) and the sample, and the end of the conduit (18) uses a PVC nut (19) plus a sealing ring (20) to fix the wire and double seal role.

[0038] In the closed structure, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com