Analysis method for air pollution by pyrolysis of raw materials in sand casting

An analysis method, sand casting technology, applied in the direction of material separation, analysis of materials, measuring devices, etc., can solve the problem of incomplete and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

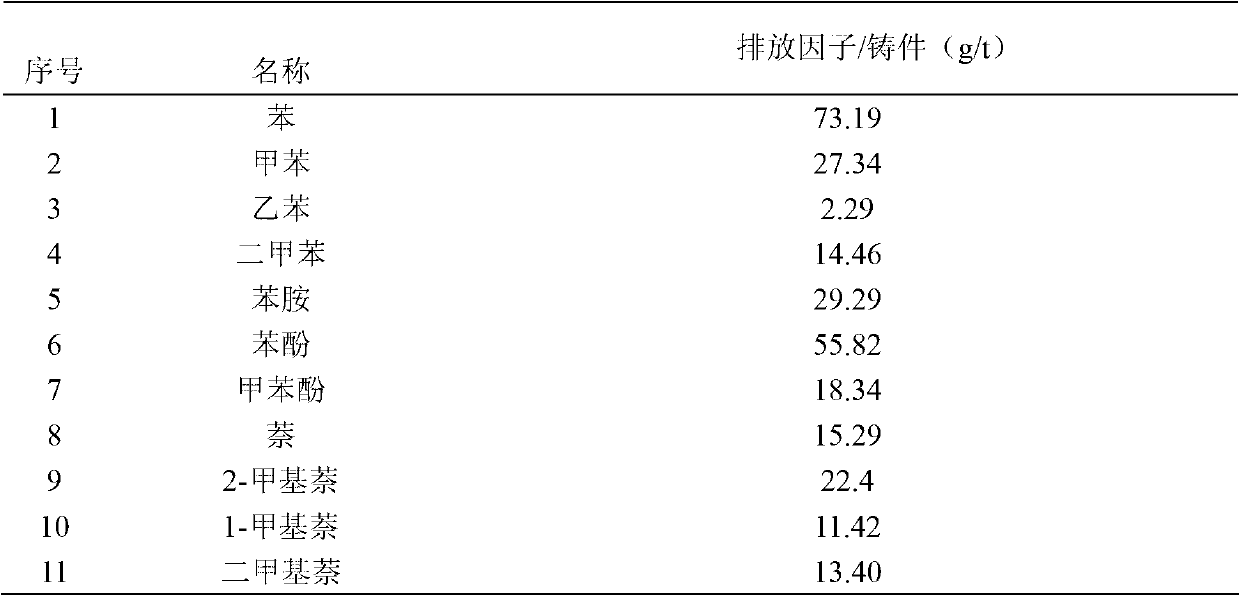

Embodiment 1

[0016] Mix coal powder (manufactured by Mingxinyuan Trading Co., Ltd.), phenolic resin binder (manufactured by Hebei Hongye Chemical Co., Ltd.), and silica sand (manufactured by Lingshou County Huayi Mineral Products Processing Factory) in a ratio of 5:1:5 Making a molding core, grinding and crushing the prepared molding core to a particle diameter of 0.1-1 mm. The sample wrapped in alloy foil was rapidly heated to 1200°C within 0.2s by using a JHP-22 Curie point thermal cracker, and the cracking time was 1s. Then the gas chromatograph directly connected with the pyrolyzer was used to separate the air pollutants produced by pyrolysis, and then identified and analyzed by mass spectrometry and flame ionization detector. The analysis results are shown in Table 1.

[0017] Among them, the operating conditions of each instrument and equipment are as follows;

[0018] Pyrolyzer: use high-purity He as the carrier gas, and heat up to the reaction temperature at a rate of 10°C Pms.

...

Embodiment 2

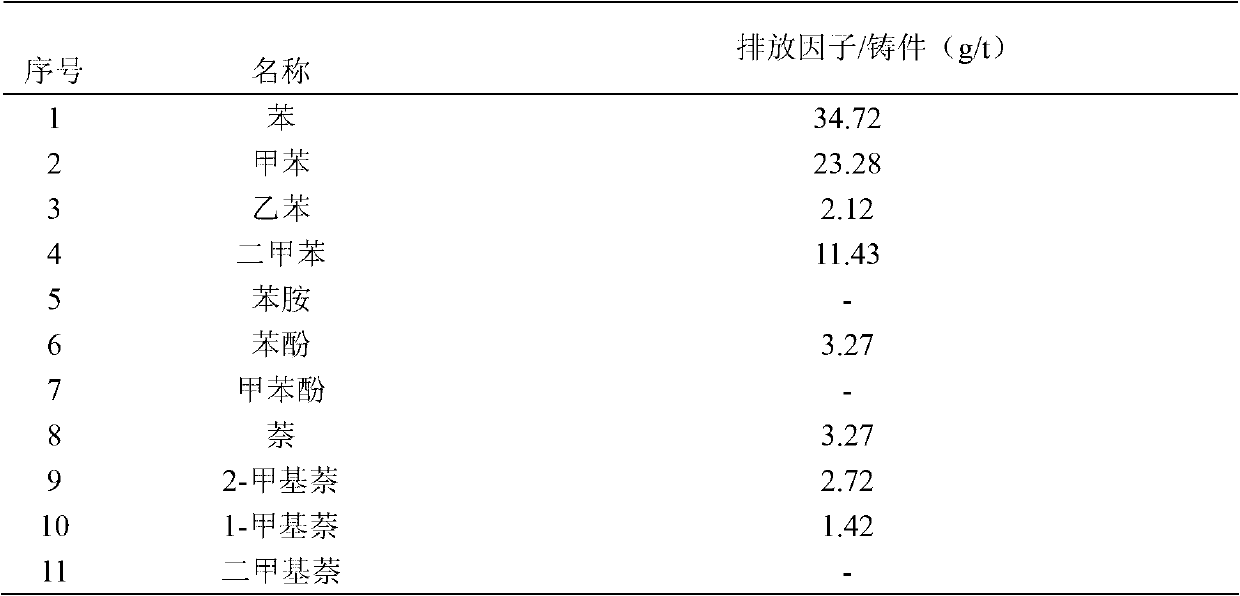

[0025] Mix coal powder (manufactured by Mingxinyuan Trading Co., Ltd.), animal glue adhesive (manufactured by Beijing Mingcai Adhesive Co., Ltd.), and silica sand (manufactured by Lingshou County Huayi Mineral Products Processing Factory) in a ratio of 5:1:5 After mixing, a molding core is made, and the prepared core is ground and crushed until the particle diameter is 0.1-1 mm. The sample wrapped in alloy foil was rapidly heated to 900°C within 0.1s by using a JHP-22 Curie point thermal cracker, and the cracking time was 5s. Then the gas chromatograph directly connected with the pyrolyzer was used to separate the air pollutants produced by pyrolysis, and then identified and analyzed by mass spectrometry and flame ionization detector. The analysis results are shown in Table 2. The operating conditions of each instrument are the same as in Example 1.

[0026] Table 2. The measured emission factors and content

[0027]

Embodiment 3

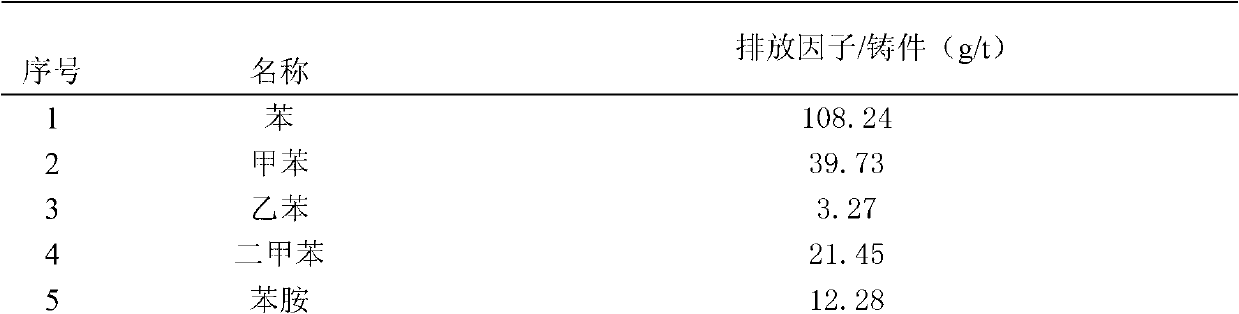

[0029] Coal powder (manufactured by Mingxinyuan Trading Co., Ltd.), naphthalene-free phenolic resin binder (phenolic resin produced by Wuxi Xinming Chemical Co., Ltd.), and silica sand (manufactured by Lingshou County Huayi Mineral Products Processing Plant) were mixed at a ratio of 5:1. : 5 to make a molding core after mixing, and grind and crush the prepared core until the particle diameter is 0.1 to 1 mm. The sample wrapped in alloy foil was rapidly heated to 1000°C within 0.2s by using a JHP-22 Curie point thermal cracker, and the cracking time was 3s. Then the gas chromatograph directly connected with the pyrolyzer was used to separate the air pollutants produced by pyrolysis, and then identified and analyzed by mass spectrometry and flame ionization detector. The analysis results are shown in Table 3. The operating conditions of the instrument are the same as in Example 1.

[0030] Table 3. The measured emission factors and content

[0031]

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com