High-temperature lithium ion battery anode slice

A technology of lithium ion battery and positive pole piece, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of increased battery polarization and long process flow, and achieves improved solvent resistance, simple process, Reduce the effect of pole piece peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

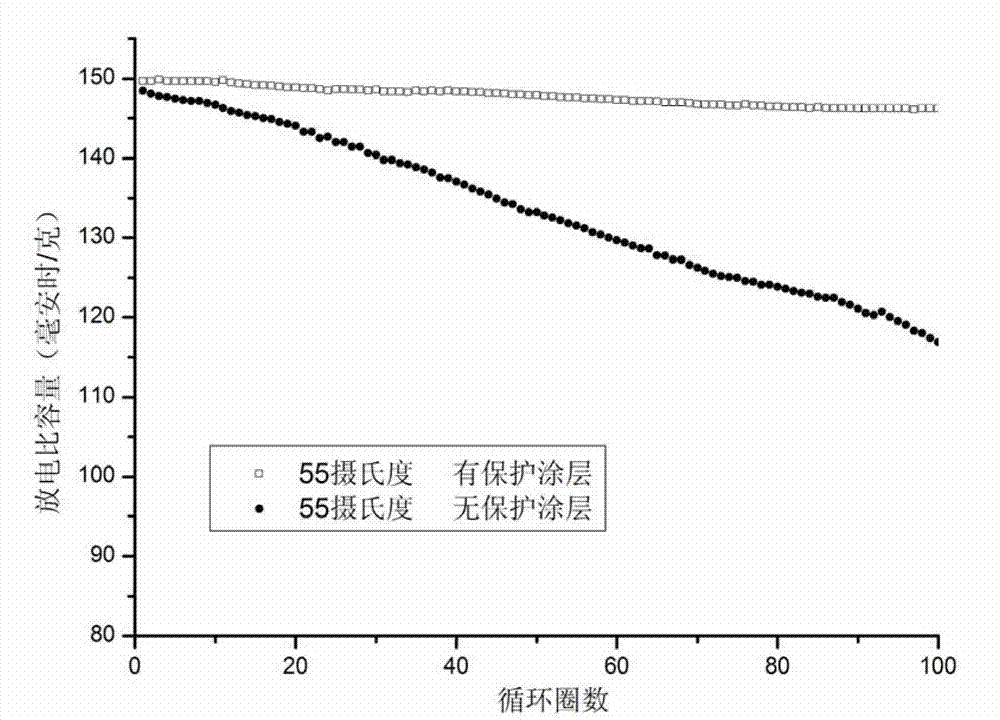

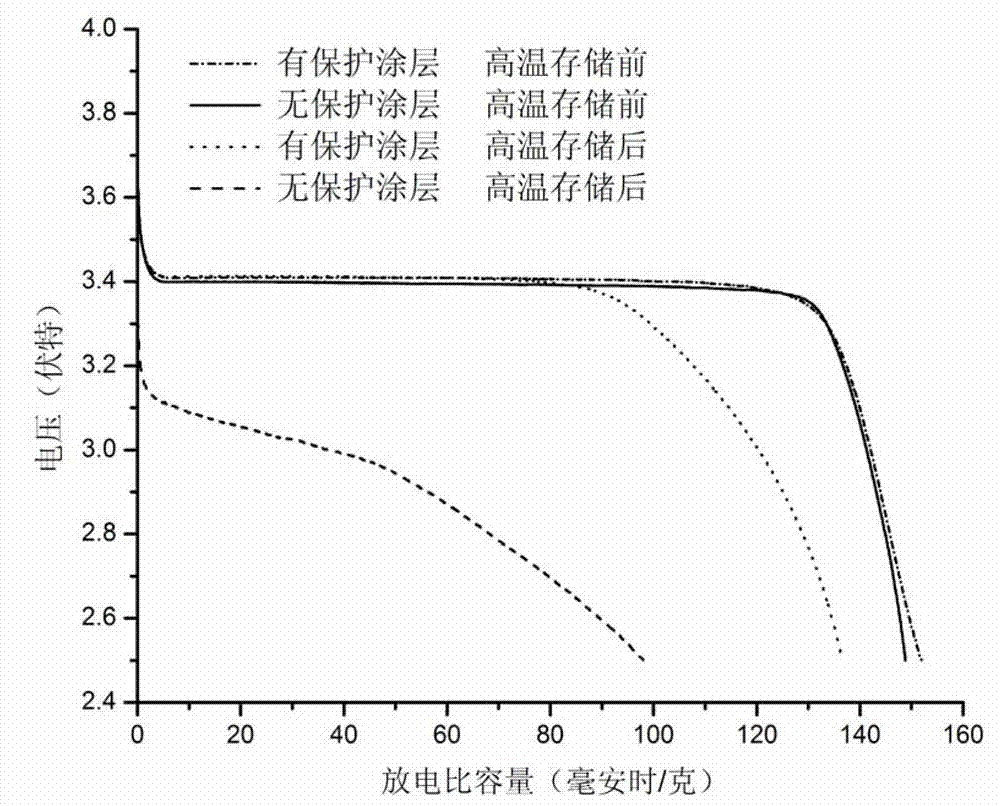

Embodiment 1

[0032] The active material in the cathode material coating is LiFePO 4 , the adhesive uses PVDF (polyvinylidene fluoride), the active material, the conductive agent, and the adhesive are mixed, and the adhesive accounts for 10% of the weight of the mixture, and the ratio of the active material and the conductive agent is 8:1 . The mixture was dissolved in the organic solvent N-methylpyrrolidone (NMP), stirred evenly until it was completely dissolved and there was no suspended matter, after slurrying, it was evenly coated on the current collector, and baked in vacuum at 110°C for 24h, with a pressure of 10 MPa Tablets for use. Mix PAA (polyacrylic acid) and conductive carbon SP in a weight ratio of 1:1, dissolve the mixture in the organic solvent N-methylpyrrolidone (NMP), stir evenly until it is completely dissolved and there is no suspended matter, and coat evenly after slurrying A lithium ion battery positive electrode with a protective coating is obtained on the spare bat...

Embodiment 2

[0034] The active material in the cathode material coating is LiMn 2 o 4 , the adhesive uses PVDF (polyvinylidene fluoride), the active material, the conductive agent, and the adhesive are mixed, and the adhesive accounts for 8% of the weight of the mixture, and the ratio of the active material and the conductive agent is 9:1 . The mixture was dissolved in the organic solvent N-methylpyrrolidone (NMP), stirred evenly until it was completely dissolved and there was no suspended matter, after slurrying, it was evenly coated on the current collector, and baked in vacuum at 100°C for 15h, with a pressure of 8 MPa Tablets for use. Mix PAANa (sodium polyacrylate) and conductive carbon KS-6 at a weight ratio of 2:1, dissolve the mixture in the organic solvent N-methylpyrrolidone (NMP), stir well until it is completely dissolved and there is no suspended matter, after pulping Uniform coating on spare battery pole pieces to obtain a lithium ion battery positive electrode with a prot...

Embodiment 3

[0036] The active material in the cathode material coating is LiFePO 4 , the adhesive uses PVDF (polyvinylidene fluoride), the active material, the conductive agent, and the adhesive are mixed, and the adhesive accounts for 9% of the weight of the mixture, and the ratio of the active material and the conductive agent is 8:1 . The mixture was dissolved in the organic solvent N-methylpyrrolidone (NMP), stirred evenly until it was completely dissolved and there were no more suspended matter, after slurrying, it was evenly coated on the current collector, and baked in vacuum at 100°C for 20h, with a pressure of 10MPa Tablets for use. Mix PAAK (potassium polyacrylate) and conductive carbon VGCF at a weight ratio of 3:1, dissolve the mixture in the organic solvent N-methylpyrrolidone (NMP), stir well until it is completely dissolved and there is no suspended matter, and evenly coat the mixture after making slurry The positive electrode of the lithium-ion battery with protective co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com