Full-automatic plate wrapping machine for lead storage batteries

A technology of lead-acid battery and cladding machine, which is applied in the direction of lead-acid battery, lead-acid battery construction, charge manipulation, etc. It can solve the problems of reduced conductivity, frequent contact, and quality impact, and reduce the probability of flying into the air , Reduce the equipment footprint and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

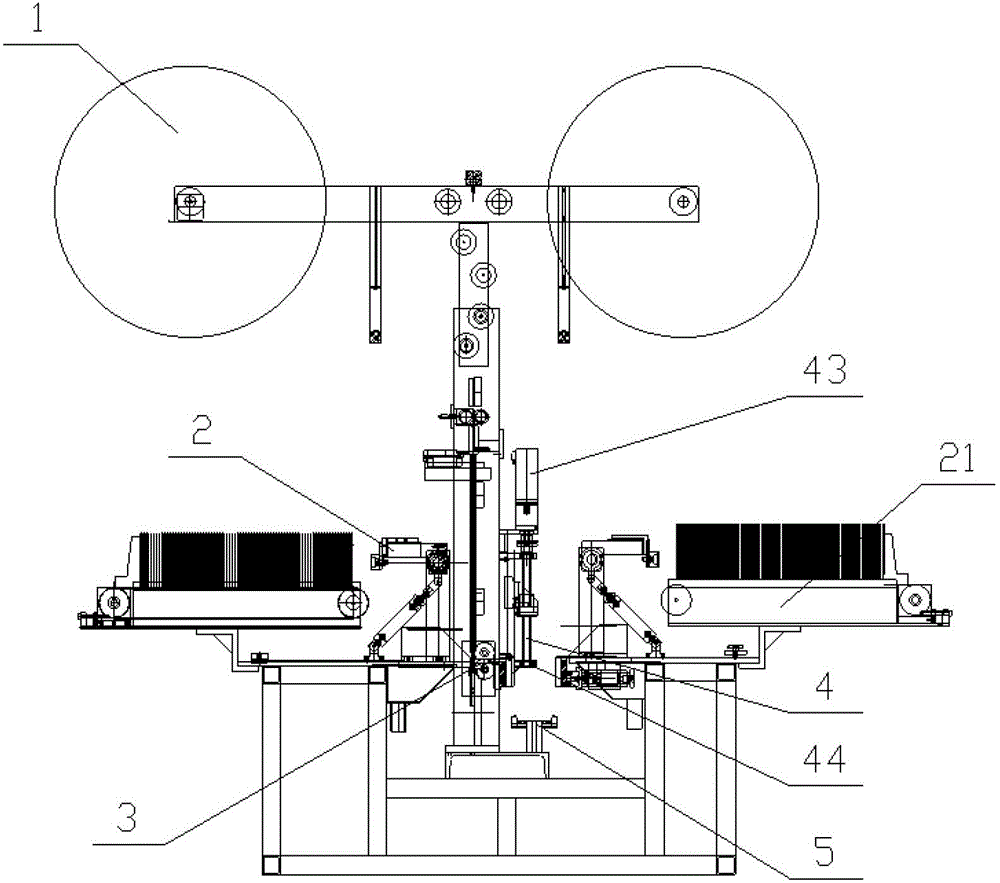

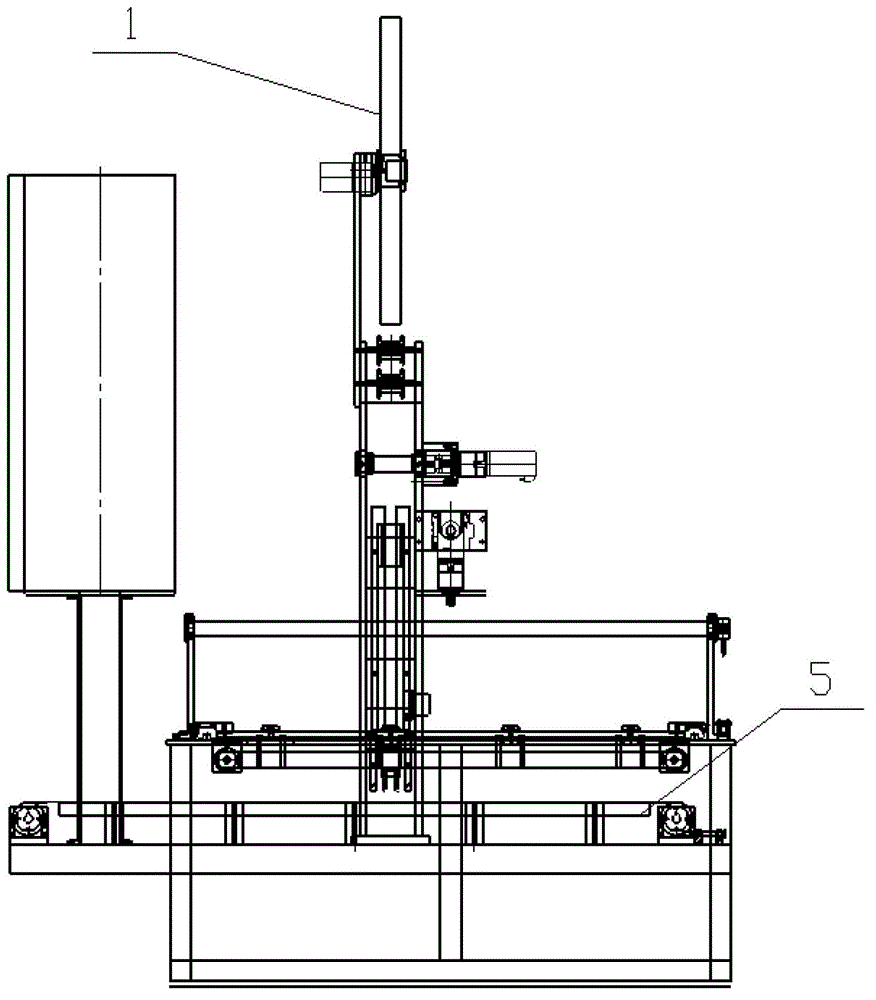

[0021] Embodiment: the full-automatic lead-acid battery cladding machine of the present invention is as figure 1 with figure 2 , the paper feeding device 1 is installed on the top of the frame, the plate feeding device 2 is located on the left and right sides of the frame, the wrapping device 3 is located in the middle of the frame, the stacking device 4 is installed on the side of the wrapping device 3, and the transfer device 5 is located on the machine In the lower part of the frame, the vacuum adsorption device 6 is connected to the electrode plate feeding device 2 through a gas pipe.

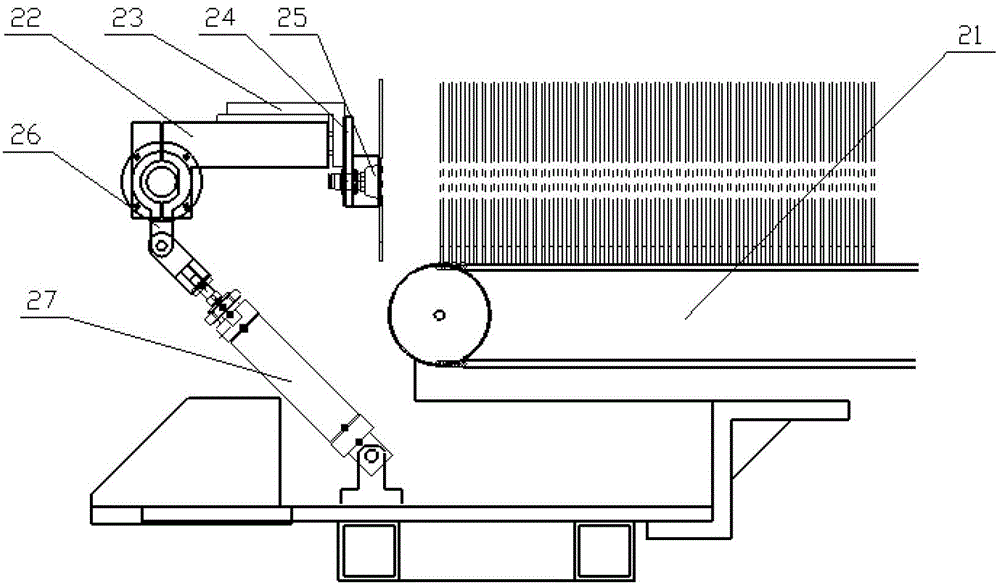

[0022] Such as image 3 The electrode plate feeding device 2 shown in the figure is equipped with a telescopic arm 23 on the rotating arm 22, a suction cup mounting seat 24 is installed on the telescopic arm 23, a suction cup 25 is installed on the suction cup mounting seat 24, and the suction cup 25 is connected to the air pipe 3 66 of the vacuum adsorption device 6 , the rotating arm 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com