Laser head device for solid laser

A laser head and laser technology, applied in the direction of lasers, laser parts, phonon exciters, etc., can solve the problems of low pumping efficiency and small absorption length of pumping light, achieve high-efficiency pumping, improve absorption efficiency, The effect of high beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 (Single-side single-channel four-pass pumping)

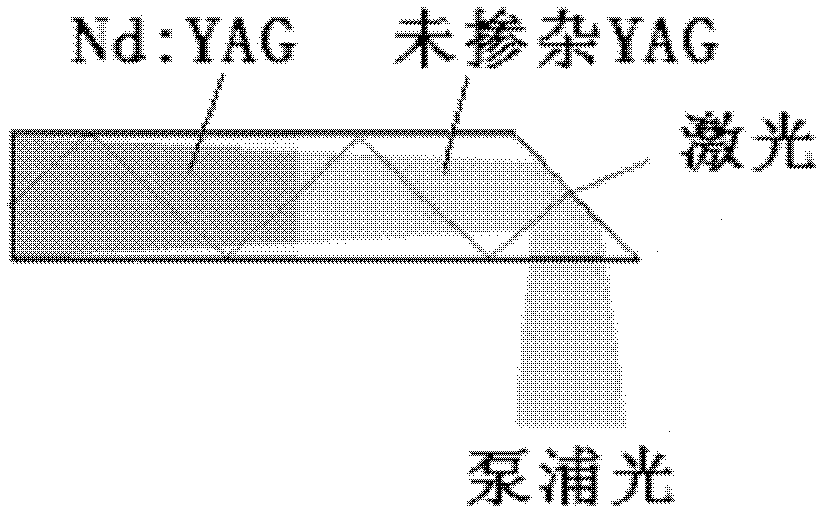

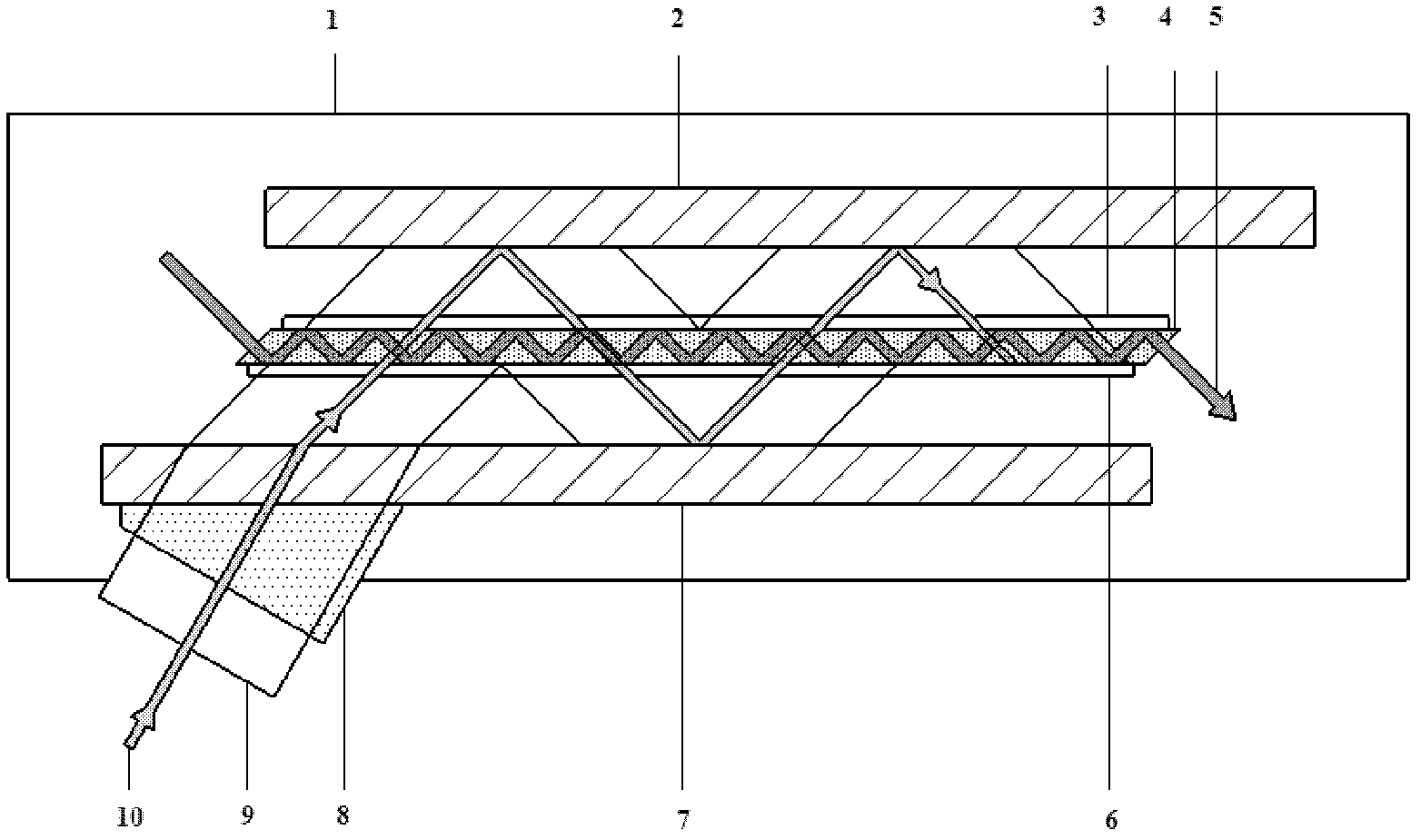

[0039] Figure 2a It is a schematic diagram of the structure of the laser head device in which the pump light pumps the slab along the side of the Z-shaped optical path according to Embodiment 1 of the present invention.

[0040] As shown in the figure, the laser head device includes a slab-shaped laser medium (for convenience, it will be simply referred to as "laser medium slab" or "slab" hereinafter) 4, and the laser medium slab is excited by the pump light to generate Laser output. The slab 4 is generally made of laser dielectric material, which can be crystal, glass or ceramics doped with Nd ions or Yb ions, including but not limited to: Nd:YAG, Nd:YVO for example 4 , Nd:GGG, Nd:YLF, Nd:YAP, Nd:S-FAP, Yb:YAG, Yb:YVO 4 , Yb:GGG, Yb:YLF, Yb:YAP, Yb:S-FAP crystals, Nd-doped ceramics, Yb-doped ceramics, Nd-doped glass, Yb-doped glass, ruby, titanium sapphire, etc. In this embodiment, the laser medium made...

Embodiment 2

[0054] Embodiment 2 (two-sided single-channel four-pass pumping)

[0055] according to image 3 The structure shown is to make a laser head device that pumps the slab along the side of the Z-shaped optical path, which is a double-sided single-channel four-pass Z-shaped pumping structure. It is improved on the basis of Embodiment 1, and one path of pumping light 12 is also added to one side of the window glass plate 2 . The pump light 12 passes through the pump light coupler 11 , emerges from the inside of the window glass plate at an angle of 45 degrees, and passes through the slat 4 four times.

Embodiment 3

[0056] Embodiment 3 (one-sided two-way four-pass pump)

[0057] according to Figure 4 The structure shown is to make a laser head device with pump light pumping the slab along the side of the Z-shaped optical path, which is a single-sided, double-channel, four-pass Z-shaped pumping structure. It is improved on the basis of Embodiment 1, and one path of pumping light 12 is also added on the other side of the window glass plate 7 . The pump light 12 passes through the pump light coupler 11 , emerges from the inside of the window glass plate at an angle of 45 degrees, and passes through the slat 4 four times. Optionally, the slats are also improved, the two ends of the slats 4 are no longer parallel, but vertical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com