Electromagnetic wave absorber, method of producing the same, flexible printed wiring board and electronic device

A manufacturing method and absorber technology, applied in the direction of printed circuit, printed circuit, printed circuit dielectric, etc., can solve the problems of increased electromagnetic noise, electronic equipment failure, cancer, etc., and achieve the effect of high electromagnetic wave absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0023] 3. Example 2 (flexible printed wiring board according to an embodiment of the present invention and electronic device according to an embodiment of the present invention) and others

[0024] [The electromagnetic wave absorber according to the first or second embodiment of the present invention, the flexible printed wiring board according to the embodiment of the present invention, the electronic device according to the embodiment of the present invention, the electromagnetic wave absorber according to the first or second embodiment of the present invention Absorbent manufacturing method, overview]

[0025] In the electromagnetic wave absorber according to the first or second embodiment of the present invention, the electromagnetic wave absorber of the flexible printed wiring board according to the embodiment of the present invention and the electromagnetic wave absorber of the electronic device according to the embodiment of the present invention desirably contain 100 pa...

Embodiment 1

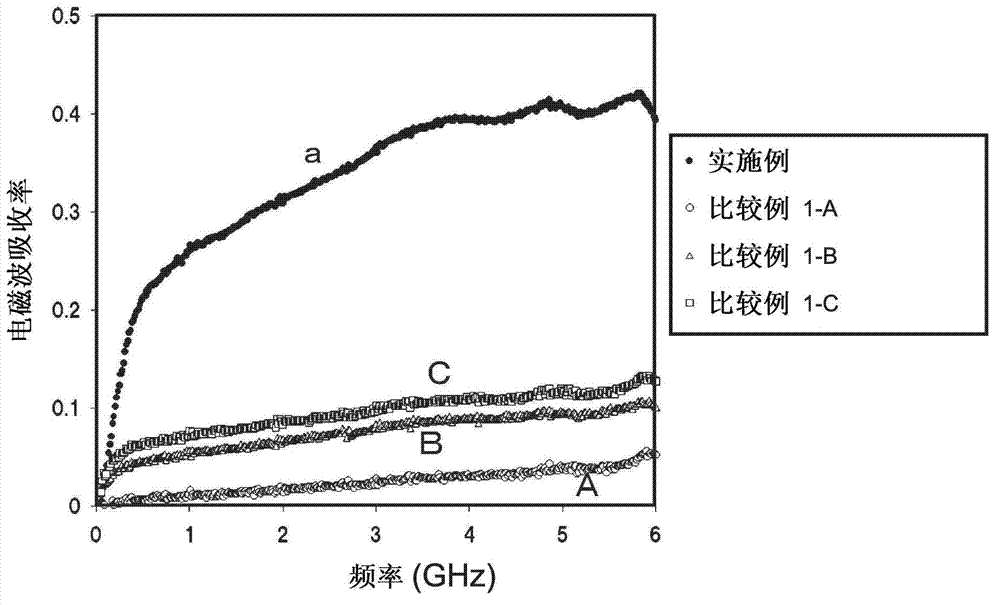

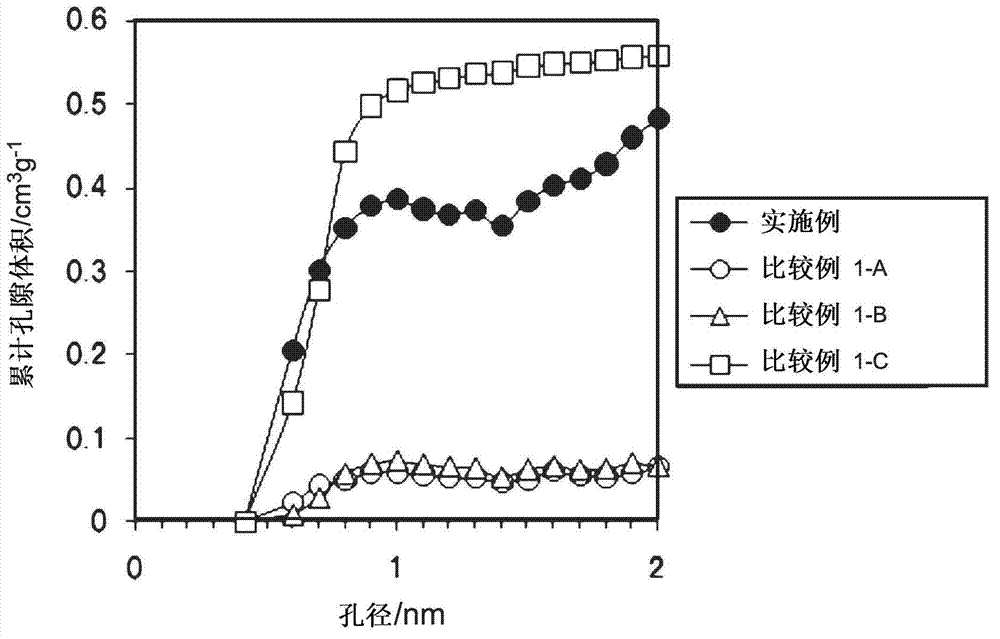

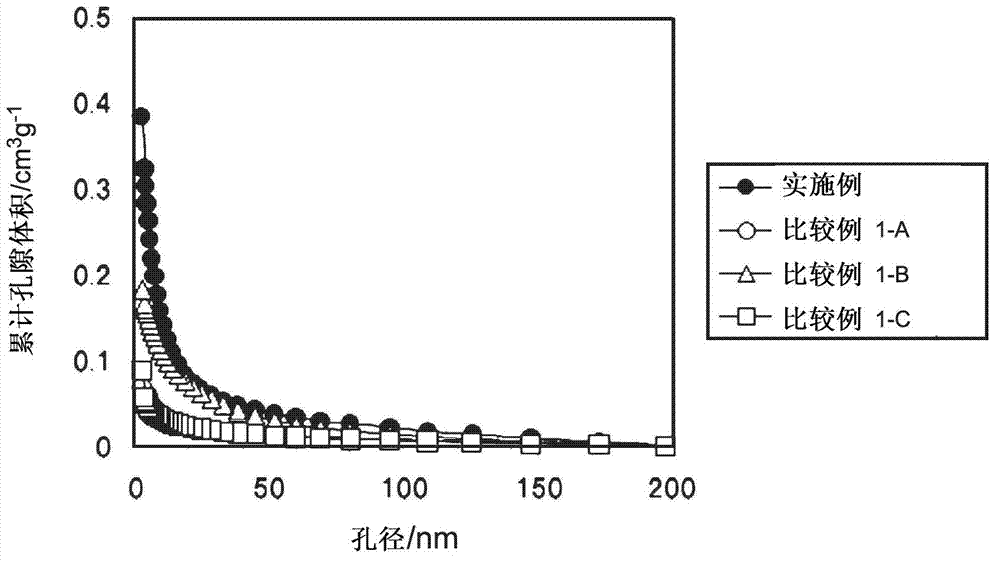

[0087] Example 1 of the present invention relates to the electromagnetic wave absorber according to the first or second embodiment of the present invention, and the manufacturing method of the electromagnetic wave absorber according to the first or second embodiment of the present invention.

[0088] As expressed according to the first embodiment of the present invention, Example 1 of the present invention is an electromagnetic wave absorber comprising a base material and a porous carbon material comprising a plant-based The material is used as a raw material, wherein the specific surface area value of the porous carbon material measured by the nitrogen BET method is 400m 2 / g or more, a silicon (Si) content of 1% or more by mass, and a pore volume measured by the BJH method of 0.2 cm 3 / g or more, and the pore volume measured by the MP method is 0.2cm 3 / g or more.

[0089]As expressed according to the second embodiment of the present invention, Example 1 of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com