High-low-temperature normal-pressure heat cycle test device

A test device, high and low temperature technology, used in laboratory appliances, heating or cooling equipment, chemical instruments and methods, etc., can solve the problems of complex system and limited temperature reduction range, and achieve the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

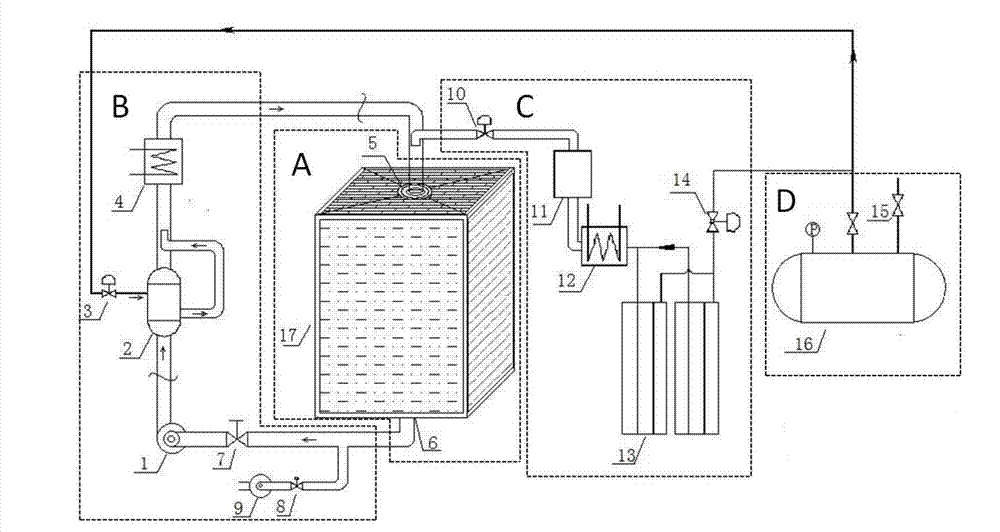

[0030] like figure 1 As shown, this embodiment includes: an environment simulation cabin A, a high and low temperature gas generation system B, a gas replacement system C, and a cold source system D.

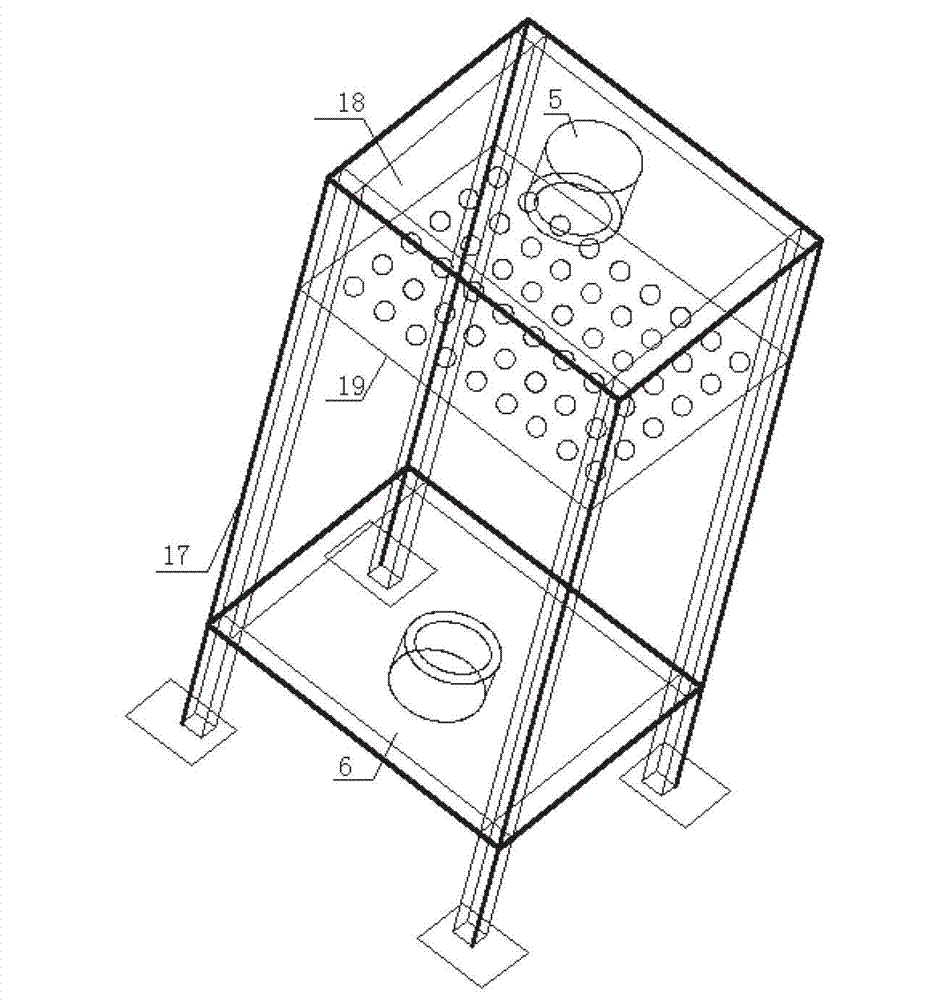

[0031] The high and low temperature gas generating system B includes: a gas-liquid heat exchanger 2, a nitrogen pipeline 19, a liquid nitrogen pipeline 18, a circulation fan 1, a circulation air valve 7, an exhaust fan 9, an exhaust valve 8, a liquid nitrogen regulating valve 3, Pipe electric heater4. Among them, the gas-liquid heat exchanger 2 is used for the mixing of liquid nitrogen and circulating nitrogen gas during the low-temperature test, and the liquid nitrogen and nitrogen gas are mixed through the pipe tee after performin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com