Steel strip edge processing method for high-frequency welded pipe and welded pipe production process

A technology of production process and processing method, which is applied in the field of high-frequency welded steel strip edge processing and high-frequency welded pipe production technology, can solve problems such as unstable weld quality, eliminate weld quality problems, and reduce cold welding defects. , The effect of uniform welding temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

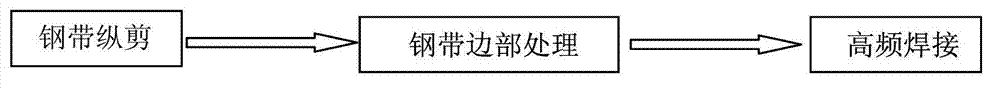

[0023] For small-diameter high-frequency welded pipe high-frequency resistance welded steel pipe production units, use such as Figure 1a The production unit shown does not have an edge milling machine. This unit is used to produce high-frequency welded pipes with a diameter of 20mm and a wall thickness of 5mm. The material is 10#, 20#, 45#, Q195 or Q235.

[0024]After the raw materials are uncoiled, they are slit into steel strips according to the required specifications. For example, slitting is carried out according to the diameter of the steel pipe of 20mm, and a certain margin (for example, 0.5mm-1.0mm) is left during the slitting to facilitate the subsequent accurate edge processing; subsequently, utilize the present invention to carry out the zone that the steel strip after slitting will be welded, heat-affected zone such as the zone of uneven tissue distribution at the welded joint and other zones that can affect the quality of the weld seam carry out edge treatment, lon...

Embodiment 2

[0027] For medium and large diameter high-frequency welded pipe high-frequency resistance welded steel pipe production units, use such as Figure 1a The production unit shown without edge milling machine is used to produce high-frequency welded pipes with a diameter of 800mm and a wall thickness of 20mm, and the materials are 10#, 20#, 45#, Q195 or Q235.

[0028] Same as Example 1, after the raw material is uncoiled, it is longitudinally cut into steel strips according to the required specifications, the steps of longitudinal cutting are the same as in Example 1, and the remaining margin of longitudinal cutting is determined according to the subsequent steps; in this embodiment, steel strips are used Brush and grinding wheel to grind off the thickness of the steel strip surface about 1mm, remove the burr on the edge of the steel strip and the micro cracks and metal separation layer formed at the section, remove oil stains and other defects, and remove the edge of the steel strip...

Embodiment 3

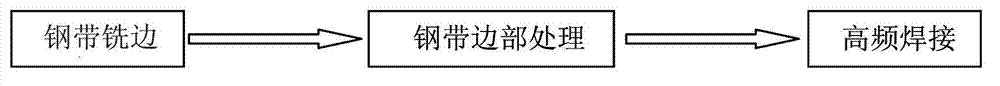

[0032] For the production line of medium and large-diameter high-frequency welded pipe high-frequency resistance welded steel pipes that have used edge milling machines, such as Figure 1b As shown, the production of high-frequency welded pipes with a diameter of 1400mm and a wall thickness of 20mm is made of 10#, 20#, 45#, Q195 or Q235.

[0033] After the raw material is uncoiled, it is slitting into steel strips according to the required specifications, and the slitting steps are the same as in the previous embodiment; then, it enters the edge milling machine for edge milling, and after edge milling, the steel strip edge treatment process of the present invention is used for edge treatment , after edge milling, carry out shot peening treatment on the corners of the steel strip, the rust on the upper and lower surfaces, and the residual adhesion dirt, etc., wherein, the selection of the shot is based on the cast iron shot or cast steel shot commonly used by those skilled in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com