Method for extracting crude fish oil from hairtail silvery fat

A technology for hairtail and crude fish, which is applied in the production of fat oil/fat and fat production, can solve the problems of destroying the original components, low extraction rate of crude fish oil, etc., and achieves the effects of easy parameter control, mild conditions and little pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

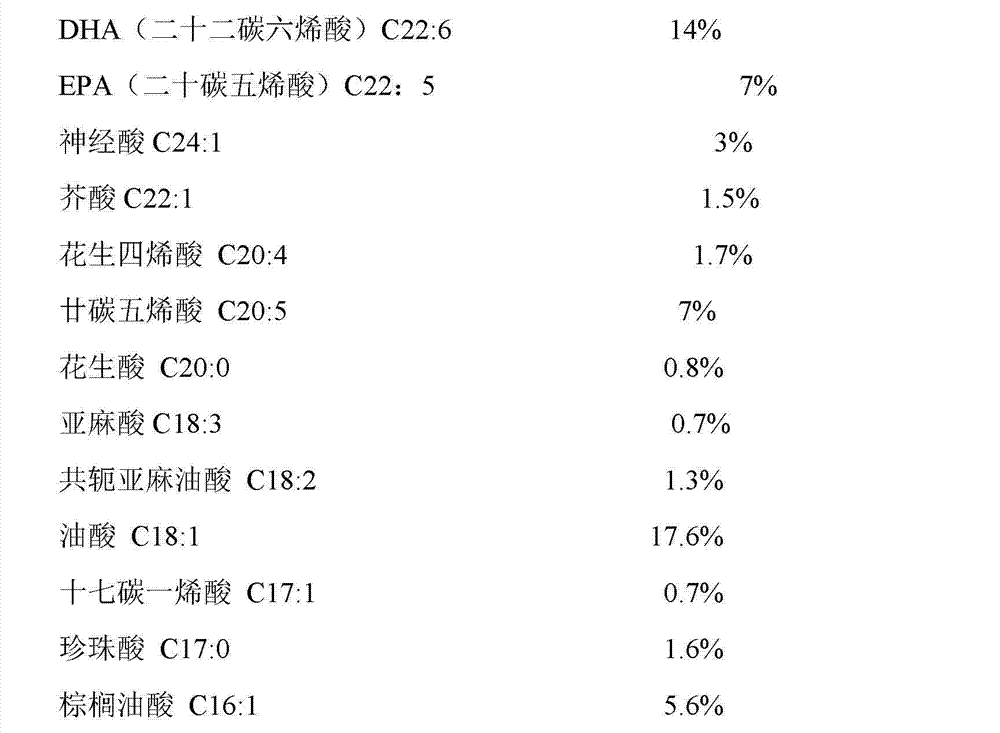

Image

Examples

Embodiment 1

[0040] Embodiment 1, a kind of method that extracts crude fish oil from hairtail silver fat, carries out following steps successively:

[0041] 1) Add 15ml of water to 15g of hairtail silver fat, then add 0.3g of neutral protease, and enzymolyze at 45°C for 2.5 hours;

[0042] 2) Use a hydrochloric acid solution with a concentration of 0.1 mol / L to adjust the pH of the enzymolysis solution obtained in step 1) to 4, so as to realize the inactivation treatment of neutral protease; then add 60ml of petroleum ether and incubate at 40°C Extract for 30min;

[0043] 3) Rotary evaporation (at 58~62°C) of the petroleum ether extract in the upper layer obtained in step 2) to volatilize the petroleum ether and obtain crude fish oil containing impurities;

[0044] 4) Centrifuge the crude fish oil containing impurities at 3000 r / min for 10 minutes, separate the obtained supernatant, and the supernatant is crude fish oil.

[0045] 3.615 g of crude fish oil was obtained, with a yield of 24...

Embodiment 2

[0047] Embodiment 2, a kind of method that extracts crude fish oil from hairtail silver fat, carries out following steps successively:

[0048] 1) Add 15ml of water to 15g of hairtail silver fat, then add 0.45g of neutral protease, and enzymolyze at 50°C for 3 hours;

[0049] 2) Use a hydrochloric acid solution with a concentration of 0.1 mol / L to adjust the pH of the enzymolysis solution obtained in step 1) to 4, so as to realize the inactivation treatment of neutral protease; then add 60ml of petroleum ether and incubate at 40°C Extract for 30min;

[0050] 3) Rotary evaporation (at 58~62°C) of the petroleum ether extract in the upper layer obtained in step 2) to volatilize the petroleum ether and obtain crude fish oil containing impurities;

[0051] 4) Centrifuge the crude fish oil containing impurities at 3000 r / min for 10 minutes, separate the obtained supernatant, and the supernatant is crude fish oil.

[0052] Obtain 4.44g of crude fish oil, yield 29.6%.

[0053]In th...

Embodiment 3

[0054] Embodiment 3, a kind of method that extracts crude fish oil from hairtail silver fat, carries out following steps successively:

[0055] 1) Add 30ml of water to 15g of hairtail silver fat, then add 0.3g of neutral protease, and enzymolyze at 45°C for 3 hours;

[0056] 2) Use a hydrochloric acid solution with a concentration of 0.1 mol / L to adjust the pH of the enzymolysis solution obtained in step 1) to 4, so as to realize the inactivation treatment of neutral protease; then add 60ml of petroleum ether and incubate at 40°C Extract for 30min;

[0057] 3) Rotary evaporation (at 58~62°C) of the petroleum ether extract in the upper layer obtained in step 2) to volatilize the petroleum ether and obtain crude fish oil containing impurities;

[0058] 4) Centrifuge the crude fish oil containing impurities at 3000 r / min for 10 minutes, separate the obtained supernatant, and the supernatant is crude fish oil.

[0059] 3.66g of crude fish oil was obtained, with a yield of 24.4%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com