Noctilucent color coated layer steel plate and manufacturing method thereof

A technology of color coating and luminous layer, applied in covering/lining, roads, road signs, etc., can solve the problems such as the preparation method of steel plate with no luminous color coating layer, and achieve guaranteed bonding effect, good luminous brightness, and process steps. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

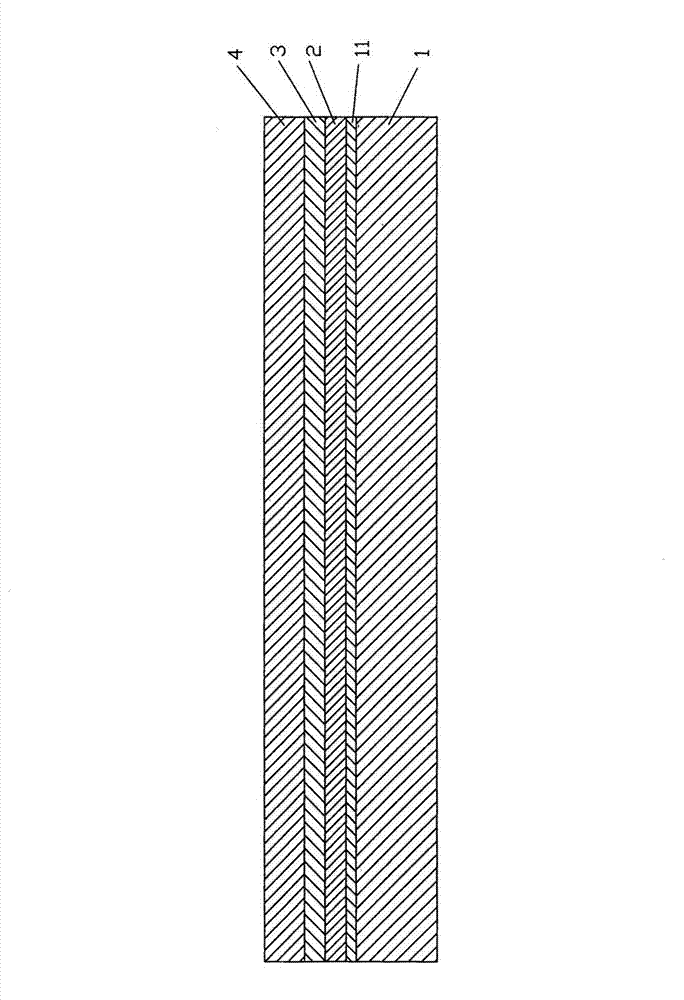

[0029] A) Select materials and clean them. Select a galvanized steel sheet with a thickness of 0.6 mm within one month from the production date. The thickness of the zinc layer of the galvanized steel sheet is 30 μm. Clean the galvanized steel sheet with a disk brush first, and then carry out alkali Washing and electrolytic cleaning, in order to remove the scale layer and / or oil stains on the surface of the galvanized steel sheet, after cleaning, dry, the drying temperature is 90 ° C, the steel plate travel speed is 60m / min, and the steel plate substrate 1 is obtained;

[0030] B) Activation treatment, chemically coating one side surface of the steel plate base 1 obtained in step A) to form a chemical coating 11 on the side surface, the thickness of the chemical coating 11 formed by chemical coating is 7 μm, the chemical coating mentioned here is to coat the surface of the steel plate substrate 1 with hexavalent chromate, and after coating the hexavalent chromate solution w...

Embodiment 2

[0035] Only change the sheet material in step A), that is, the steel plate, to an galvanized steel plate with a thickness of 1.2 mm, and the thickness of the aluminum-zinc layer to 65 μm. Change the final drying temperature to 70°C, change the steel plate traveling speed to 50m / min; change the thickness of the chemical coating 11 in step B) to 10 μm, and change the drying temperature after coating the hexavalent chromium solution to 120°C, Change the drying time to 12s; change the thickness of the primer coating 2 in step C) to 10 μm, change the drying and curing temperature and time after applying the primer to 200°C and 46s respectively, and change the thickness of the topcoat coating 3 Change the thickness to 40 μm, change the temperature and time of drying and curing after coating the topcoat to 250°C and 54s respectively; change the thickness of the luminous layer 4 in step D) to 130 μm, and change the temperature and time of drying and curing respectively Change to 200...

Embodiment 3

[0037] Only change the thickness of the sheet material in step A), that is, the steel plate, to 0.2mm galvanized steel plate, and change the thickness of the galvanized zinc layer to 10μm. The drying temperature is changed to 80°C, and the steel plate travel speed is 55m / min; the thickness of the chemical coating 11 in step B) is changed to 8.5μm, and the drying temperature after coating the hexavalent chromium solution is changed to 110°C, and the drying time is Change it to 9s; change the thickness of the primer coating 2 in step C) to 25 μm, change the drying and curing temperature and time after applying the primer to 215°C and 42s respectively, and change the thickness of the topcoat 3 to Change the temperature and time of drying and curing after coating the topcoat to 230°C and 50s respectively; change the thickness of the luminous layer 4 in step D) to 90 μm, and change the temperature and time of drying and curing to 215°C and 55s, wherein: the luminous coating is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com