A kind of fluorescent powder for white light LED for lighting display and its preparation and application

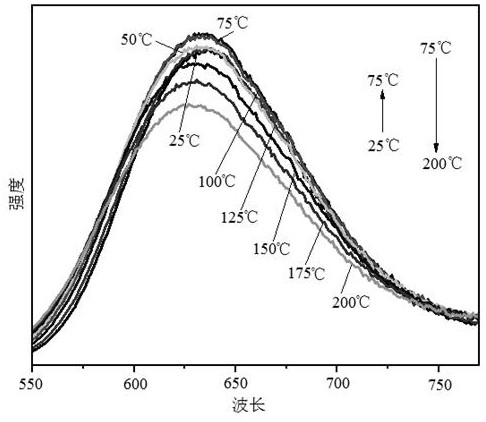

A technology of red phosphor powder and LED chip, applied in the field of red phosphor powder, can solve problems such as difficulty in meeting the application requirements of high-performance devices, and achieve the effects of easy industrial production, good thermal stability, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] According to the chemical formula (Sr 0.85 Ca 0.15 ) 1.95 Si 4.7 Al 0.3 N 7.7 O 0.3 :0.05Eu 2+ The stoichiometric ratio of each raw material in the 3 N 2 , Ca 3 N 2 , Si 3 N 4 , AlN, Al 2 O 3 and EuF 3 , AlN and Al 2 O 3 The molar ratio is 1:1, and then weigh the co-solvent Li 3 N and the carbon powder of the impurity-removing reagent are mixed with the taken raw materials to form a mixture, and the mass fraction of the co-solvent and the impurity-removing reagent in the mixture are both 1 wt%. After fully grinding and mixing evenly, put it in a boron nitride crucible, put it in a high-temperature tube furnace, and fire it at 1500 ° C for 4 hours under a nitrogen atmosphere. Use red phosphors for white LEDs.

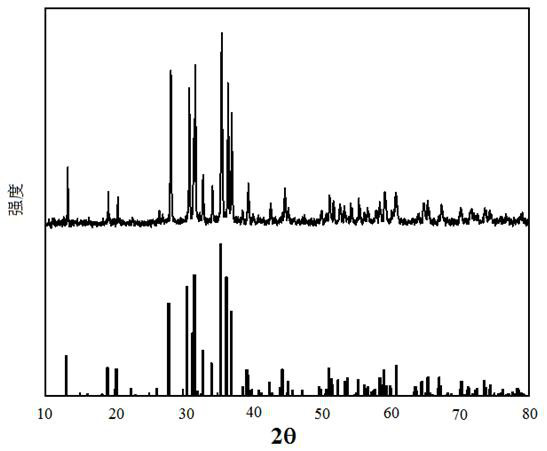

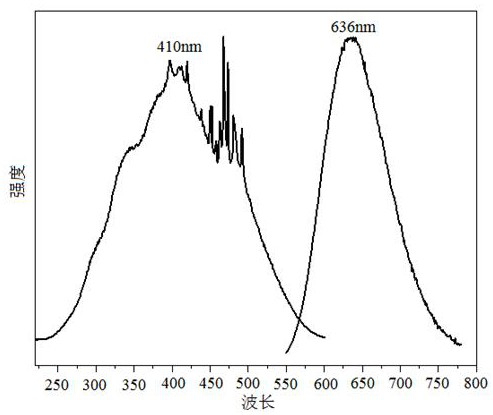

[0032] figure 1 are the XRD pattern and standard pattern (ICSD: 401500) of the phosphor prepared in Example 1, from figure 1 It can be seen that the XRD pattern of the phosphor prepared in Example 1 is the same as the 2 Si5 N 8 The compariso...

Embodiment 2

[0042] According to the chemical formula (Sr 0.85 Ca 0.15 ) 1.95 Si 4.1 Al 0.9 N 7.1 O 0.9 :0.05Eu 2+ The stoichiometric ratio of each raw material in the 3 N 2 , Ca 3 N 2 , Si 3 N 4 , AlN, Al 2 O 3 and EuF 3 , AlN and Al 2 O 3 The molar ratio is 1:1, and then weigh the co-solvent Li separately. 3 N and impurity-removing reagent carbon powder are mixed with the raw materials to form a mixture, and the mass fraction of co-solvent and impurity-removing reagent in the mixture are both 1 wt%; after fully grinding and mixing, place in a boron nitride crucible, and then put In a high-temperature tubular furnace, it is fired at 1500° C. for 4 hours in a nitrogen atmosphere, and then cooled to room temperature with the furnace to obtain a red phosphor for white light LEDs for lighting display.

[0043] Figure 9 are the XRD pattern and standard pattern (ICSD: 401500) of the phosphor prepared in Example 2, from Figure 9 It can be seen that the XRD pattern of the ph...

Embodiment 3

[0046] According to the chemical formula (Sr 0.70 Ca 0.30 ) 1.95 Si 4.7 Al 0.3 N 7.7 O 0.3 :0.05Eu 2+ The stoichiometric ratio of each raw material in the 3 N 2 , Ca 3 N 2 , Si 3 N 4 , AlN, Al 2 O 3 and EuF 3 , AlN and Al 2 O 3 The molar ratio is 1:1, and then weigh the co-solvent Li separately. 3 N and the carbon powder of the impurity-removing reagent are mixed with the raw materials taken to form a mixture, and the mass fraction of the co-solvent and the impurity-removing reagent in the mixture are both 1 wt%. After fully grinding and mixing evenly, it was placed in a boron nitride crucible, and then placed in a high-temperature tube furnace for firing at 1500°C for 4 hours in a nitrogen atmosphere, and then cooled to room temperature to obtain a red phosphor for white LEDs.

[0047] Figure 11 are the XRD pattern and standard pattern (ICSD: 401500) of the phosphor prepared in Example 3, from Figure 11 It can be seen that the XRD pattern of the phosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com