Two-source heat pump multi-function machine

A multifunctional machine, source heat pump technology, applied in the direction of refrigerators, fluid heaters, machine operation modes, etc., can solve the problems of high power and affecting refrigerant distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

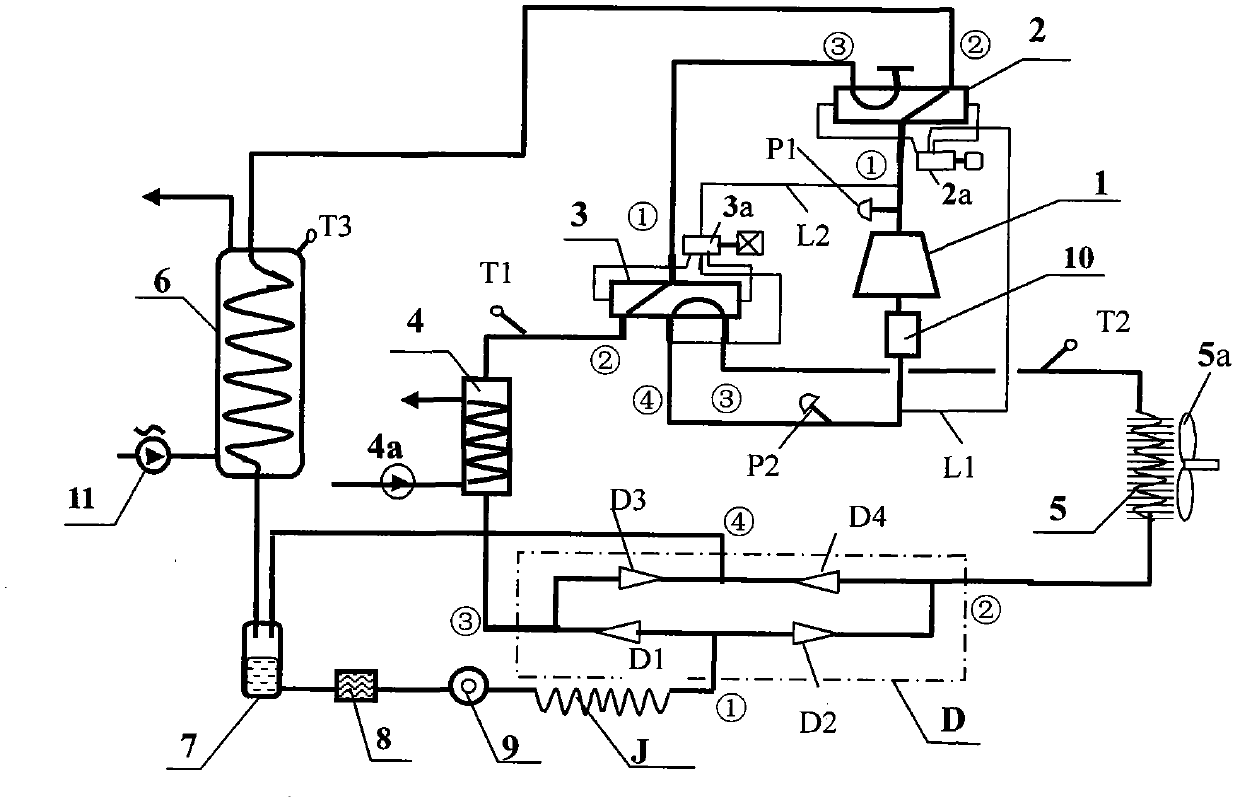

[0059] Embodiment 1, figure 1 It is a schematic diagram of the basic structure of a wind / water two-source heat pump multifunctional machine according to Embodiment 1 of the present invention. The device includes a refrigerant circuit system, a hot water heat exchange system, an air-conditioning water heat exchange system, and a signal acquisition and automatic control system; The refrigerant circuit system described above includes a compressor 1, a three-way valve 2, a four-way valve 3, a water heat exchanger 4, an air heat exchanger 5, a hot water heat exchanger 6, a liquid receiver 7, a filter 8, The sight glass 9 and the restrictor J are thermal expansion valves and gas-liquid separators 10, and the rectification mechanism D is composed of four one-way valves D1, D2, D3 and D4 of the first, second, third and fourth; rectification There are four interfaces to the mechanism D: the first interface ① is the parallel interface of the inlets of the first and second one-way valves...

Embodiment 2

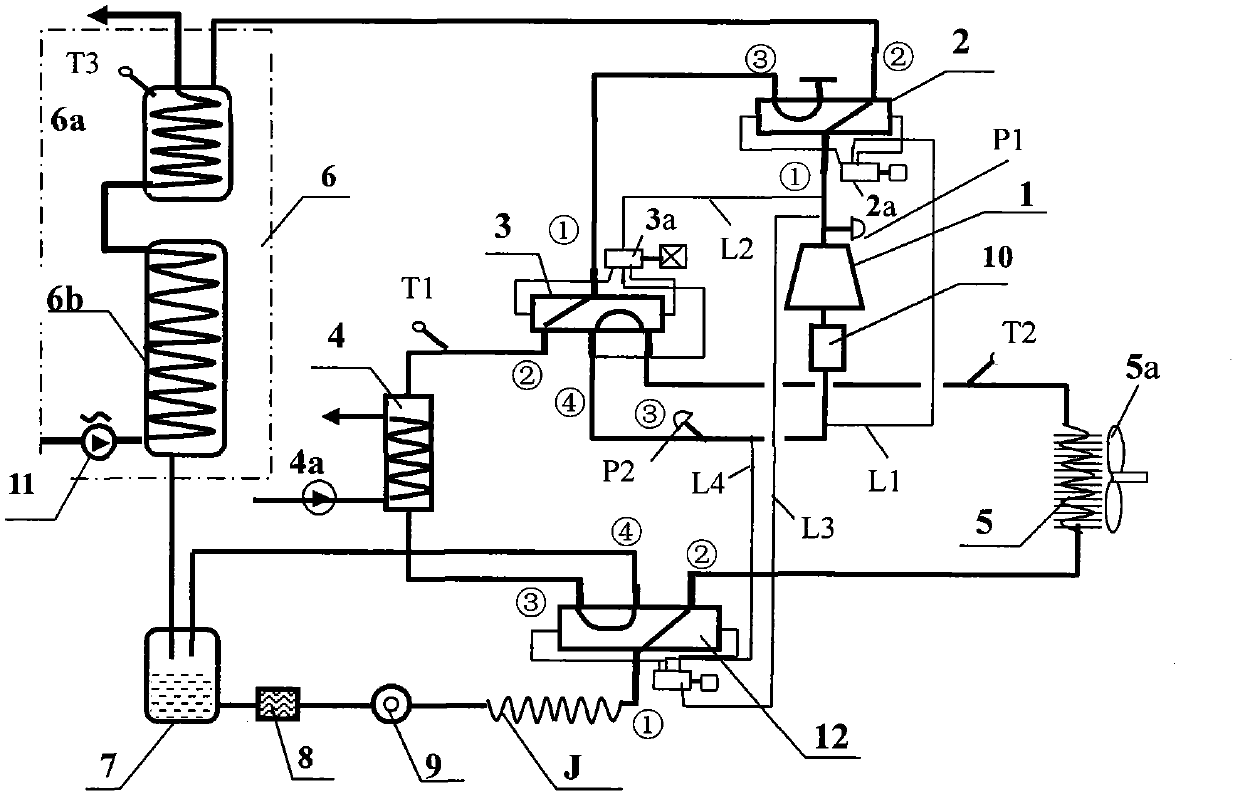

[0067] Embodiment 2, figure 2 It is Embodiment 2 of the present invention, the basic structure schematic diagram and working principle explanatory diagram of the second type wind / water two-source heat pump multifunctional machine, and its difference from Embodiment 1:

[0068] (1) figure 1 The rectification mechanism D composed of four one-way valves in the refrigerant circuit system is figure 2 is replaced by a second four-way valve 12; the alternative scheme for the connection of the second four-way valve in the refrigerant circuit system is: the first, second, third, and fourth ports ①, ②, and ③ of the second four-way valve , ④, respectively replace figure 1 The first, second, third, and fourth ports ①, ②, ③, and ④ of the rectification mechanism D, that is, the first, second, third, and fourth ports of the second four-way valve are respectively connected to the throttle J of the refrigerant circuit. The outlet, the lower end interface of the wind heat exchanger 5, the ...

Embodiment 3

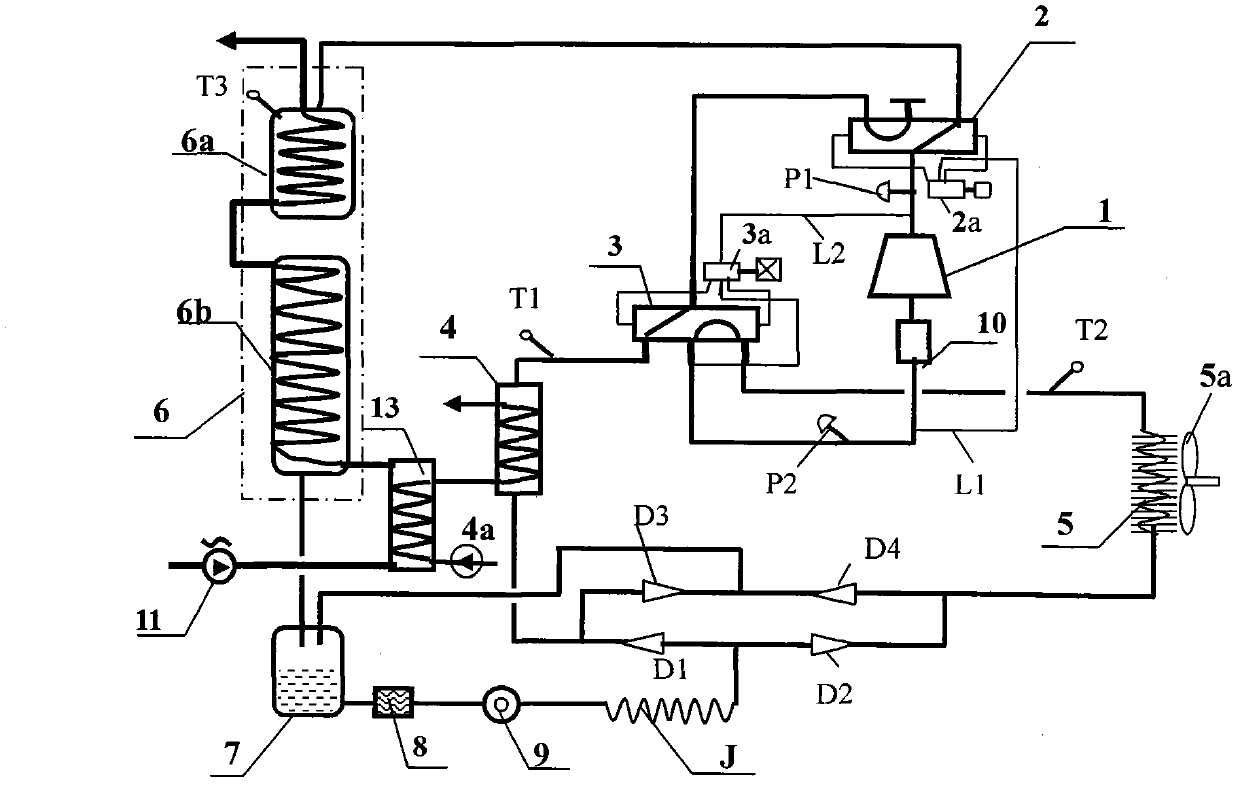

[0076] Embodiment 3, image 3 It is a schematic diagram of the basic structure and an explanatory diagram of the working principle of a waste heat recovery type wind / water dual-source heat pump multifunctional machine in Embodiment 3 of the present invention. Compared with Embodiment 1, the system has a waste heat recovery heat exchanger 13 added.

[0077] image 3 device shown, with figure 1 Compared with the device shown, the refrigerant circulation loop system is the same, except that in the purified water heating and heat exchange system, the device in embodiment 3 adds a waste heat recovery heat exchanger 13; the waste heat recovery heat exchanger is a clean water / Waste water heat exchanger; the waterway connection mode of the clean water heating heat exchange system is that a frequency conversion water pump 11 is installed on the water inlet pipe, and the water inlet pipe is connected with the clean water inlet of the waste heat recovery heat exchanger 13, and the net ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com