Heat exchanger with compensating ring

A heat exchanger, segmented technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as fracture, preheating expansion of pipelines, accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

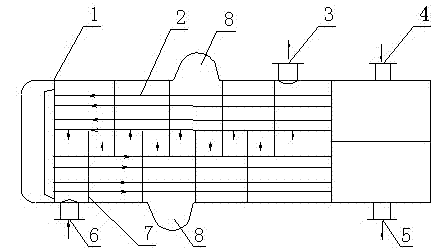

[0009] like figure 1 As shown, the heat exchanger with a compensation coil includes a shell 1, and a partition plate 7 and a cold water pipe 2 are arranged inside the shell 1. The shell 1 is provided with a hot water inlet pipe 6, a hot water outlet pipe 3, and a cold water inlet pipe. The pipe 4 and the cold water outlet pipe 5, the cold water inlet pipe 4 and the cold water outlet pipe 5 are separated in the middle, the cold water inlet pipe 4 is connected to the cold water pipe 2, and the cold water pipe 2 is a segmented water pipe, and the two segmented water pipes communicate with each other through a closed space One end of the cold water pipe 2 is fixed on the shell 1, and the other end is freely supported by the shell 1; the heat exchanger shell 1 has a compensation ring 8.

[0010] The shape of the compensation ring 8 is arched, distributed on the upper and lower sides of the housing 1 , and the arched space of the compensation ring 8 communicates with the inner space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com