Method for detecting micro lens fixed focus based on grating shear interference detection system

A detection method and interference detection technology, applied in the field of optical detection, can solve the problems of low measurement efficiency, high measurement cost, complicated operation, etc., and achieve the effect of simple and easy operation and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

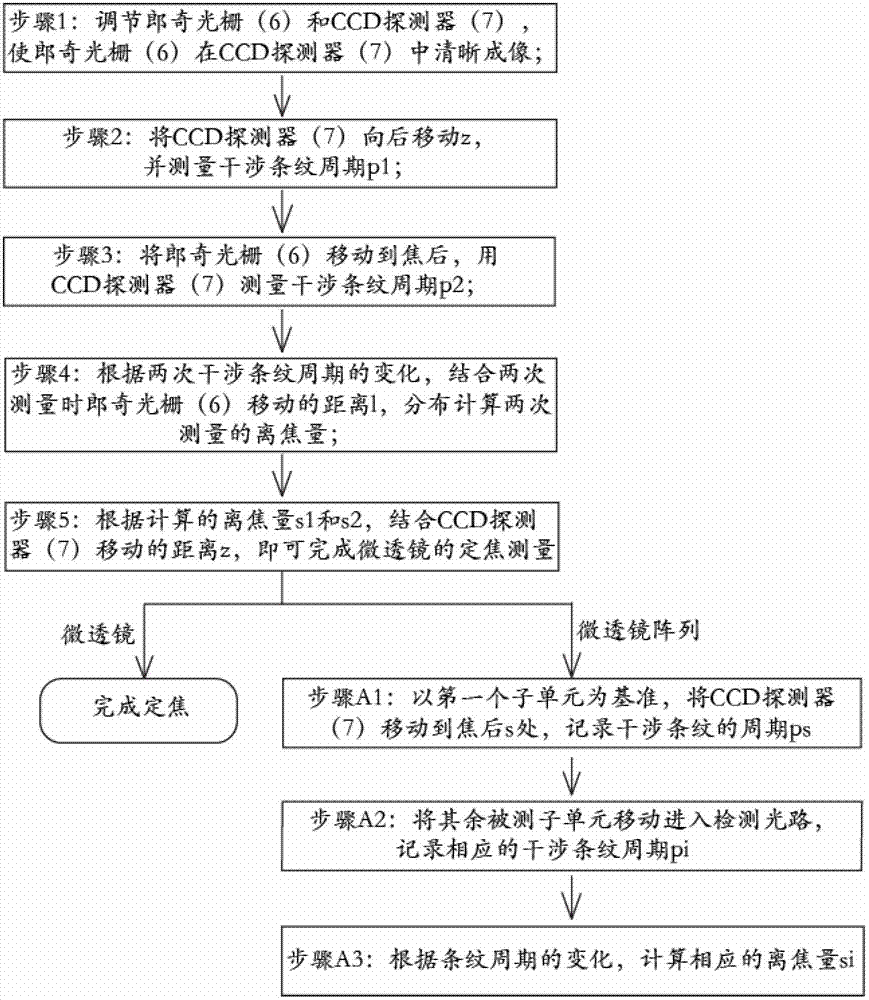

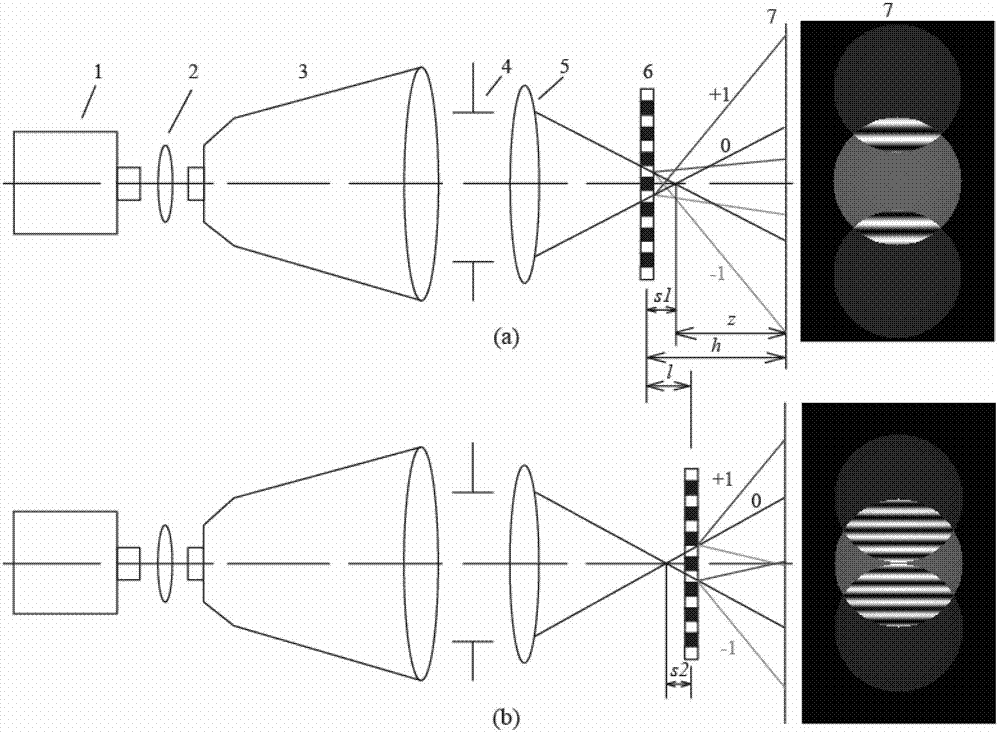

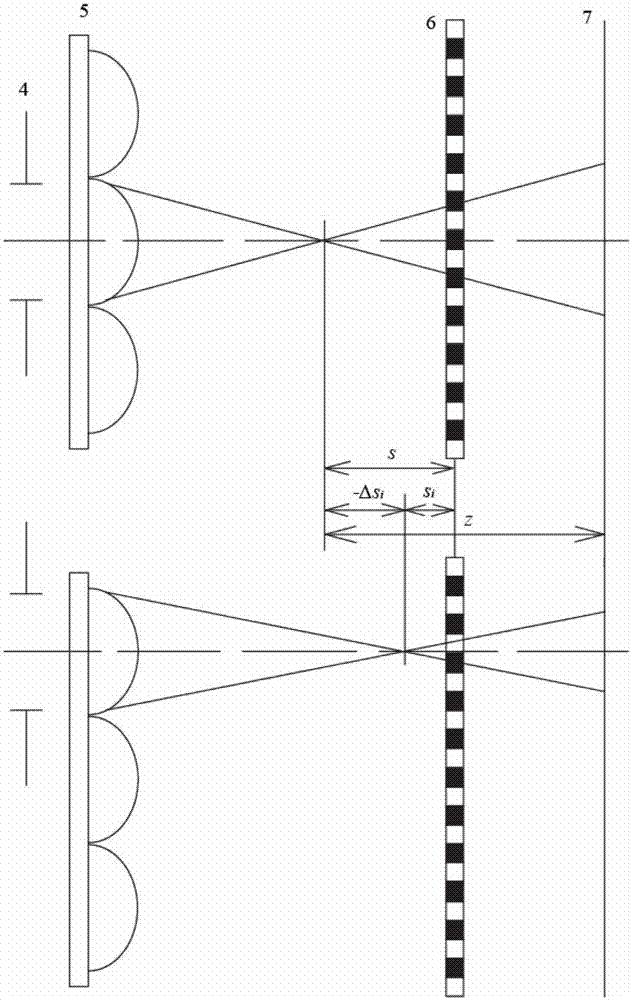

[0039] The present invention will be further described in conjunction with accompanying drawing, figure 2Among them, a microlens fixed-focus detection method based on a grating shearing interference detection system, the detection system consists of a He-Ne laser 1, a condenser lens 2, a collimator 3, an aperture baffle 4, a microlens to be tested 5, a Lang Composed of an odd grating 6 and a CCD detector 7, the fixed-focus detection of the microlens 5 to be tested is completed through the fringe changes produced by the interference of the 0th order and the 1st order diffracted light of the Langchic grating 6, and the He-Ne laser 1 passes through the condenser lens 2 and After the collimator 3 collimates and expands the beam, it passes through the aperture baffle 4 and enters the measured microlens 5 with a plane wavefront. The method can complete the fixed-focus measurement of the measured microlens 5 through the following steps:

[0040] Step 1: Place the Langki grating 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com