Planar continuous loading testing device for numerical-control movable worktable

A technology for loading a test device and a mobile workbench, which is applied to measuring devices, testing of machine/structural components, instruments, etc., and can solve the problems of difficult follow-up loading, inability to realize workbench loading, and inability to realize plane loading forms, etc. To achieve the effect of simplified structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

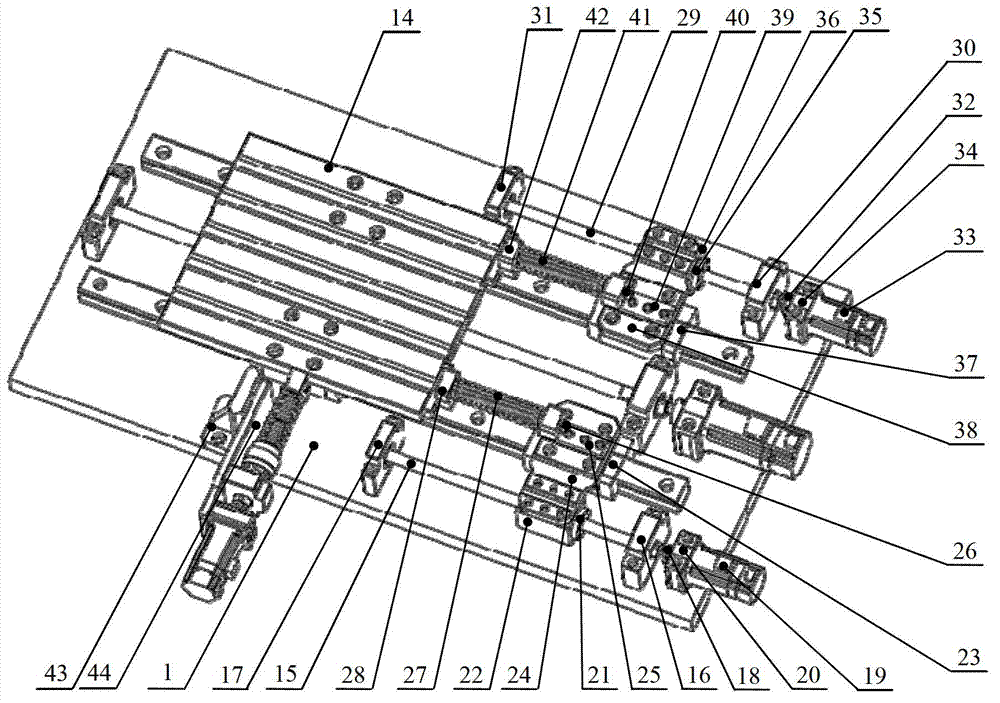

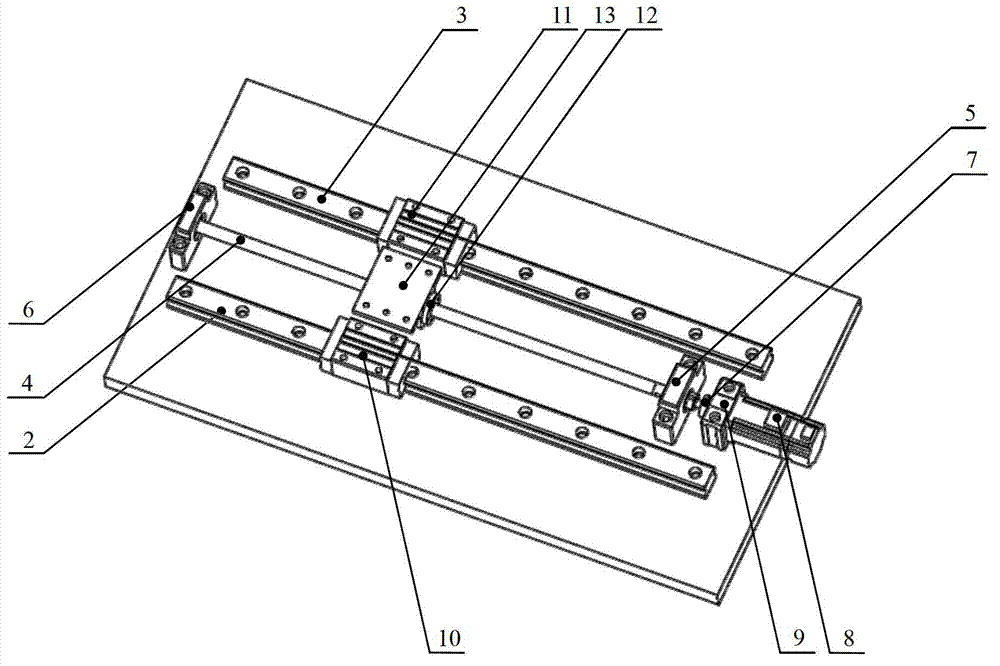

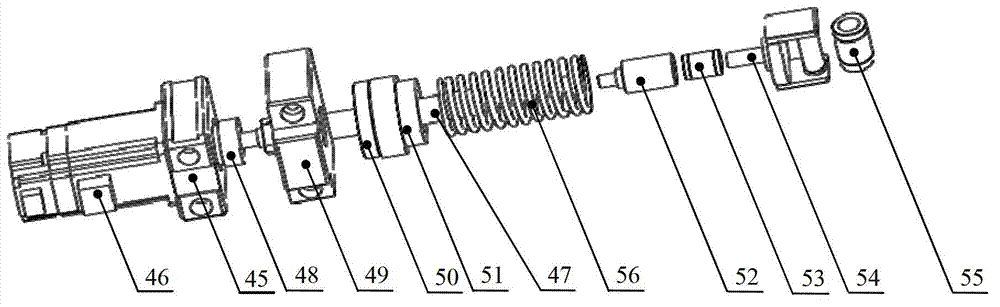

[0021] Below in conjunction with accompanying drawing and specific embodiment, the plane continuous loading test device that the present invention proposes is used for numerically controlled mobile workbench and is described in detail:

[0022] Such as figure 1 with figure 2 As shown, the structure of the analog numerical control mobile workbench is: two parallel first sliding guide rails 2 and second sliding guide rails 3 are arranged on the base 1; A first ball screw 4 is arranged in parallel between the guide rails 3; the first ball screw 4 is carried out by the first ball screw fixed support seat 5 and the first ball screw floating support seat 6 fixed on the base 1. Supported, and directly connected with the first servo motor 8 through the first coupling 7 at the protruding end of the first ball screw fixed support seat 5; the first servo motor 8 passes through the first motor seat 9 Fixed on the base 1; the first slider 10 is arranged on the first sliding guide rail 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com