Heat engine with external heat source and associated power generation unit and vehicle

A heat engine and heat source technology, applied to engine components, steam engine devices, combustion engines, etc., can solve problems such as doubts about effectiveness, and achieve the effects of stress reduction, cost reduction, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

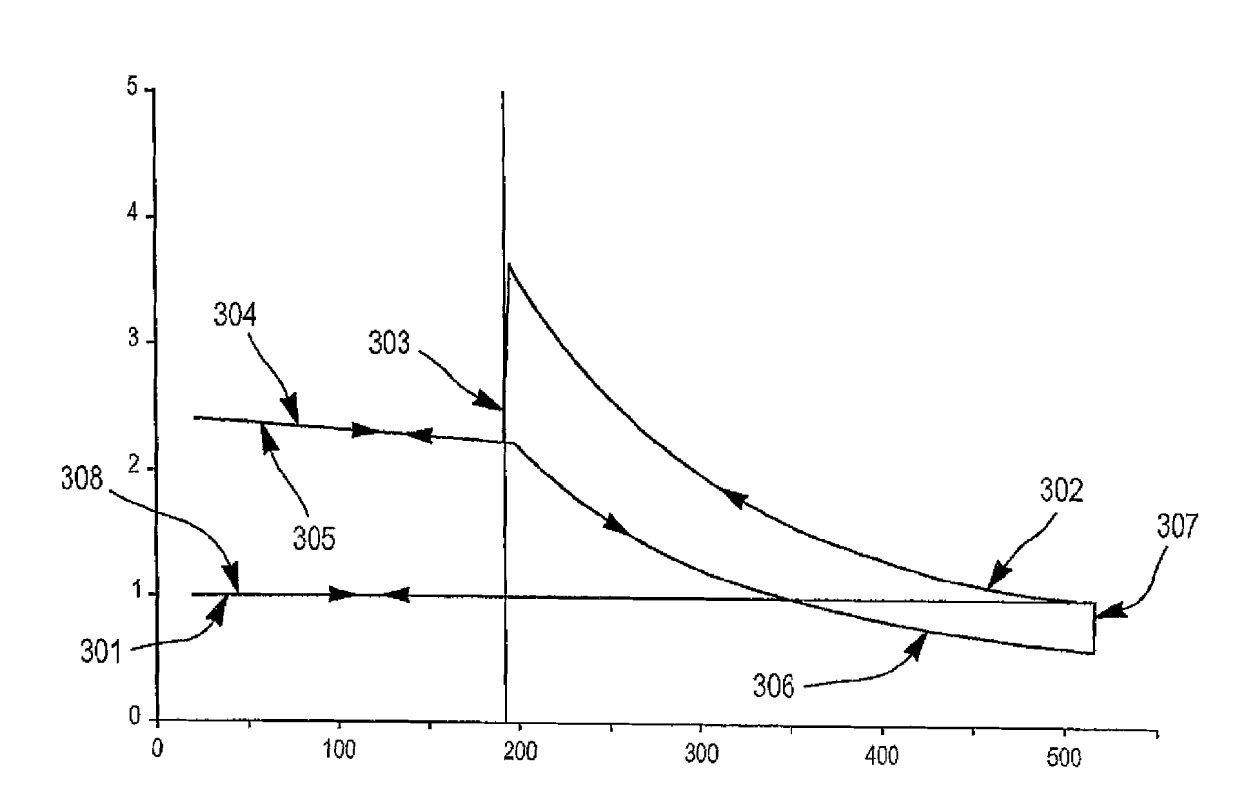

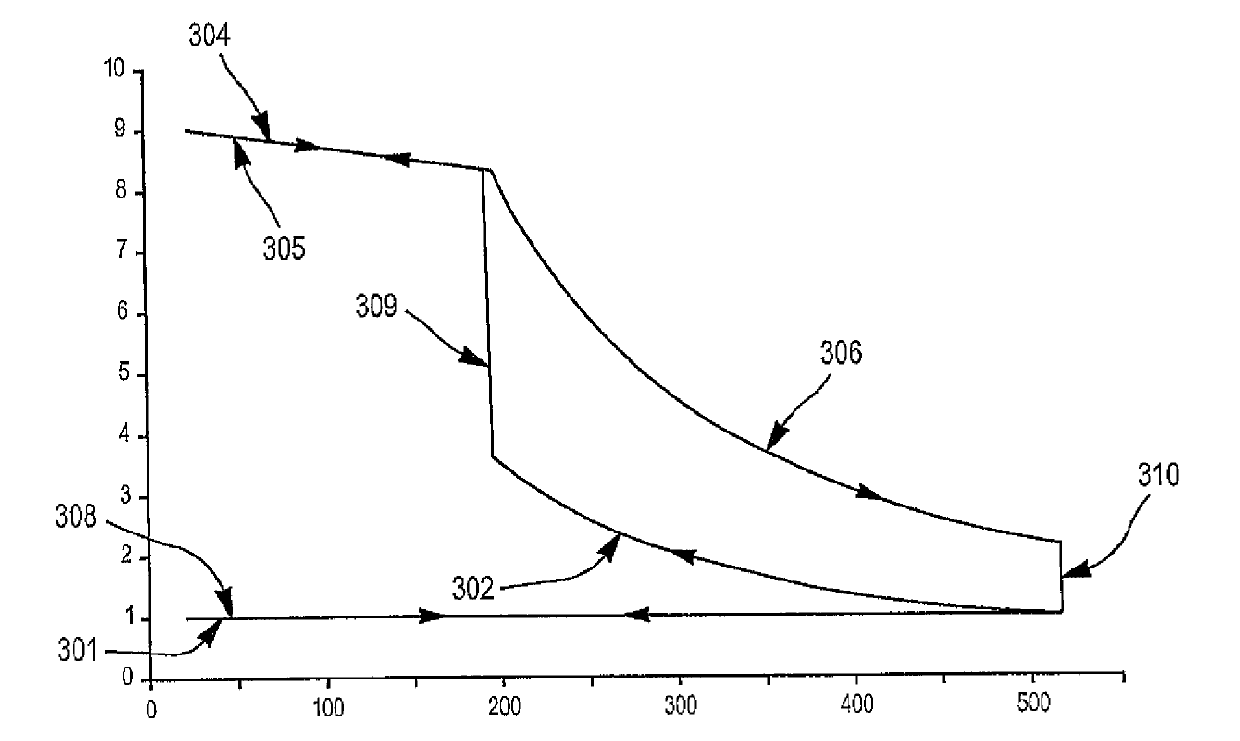

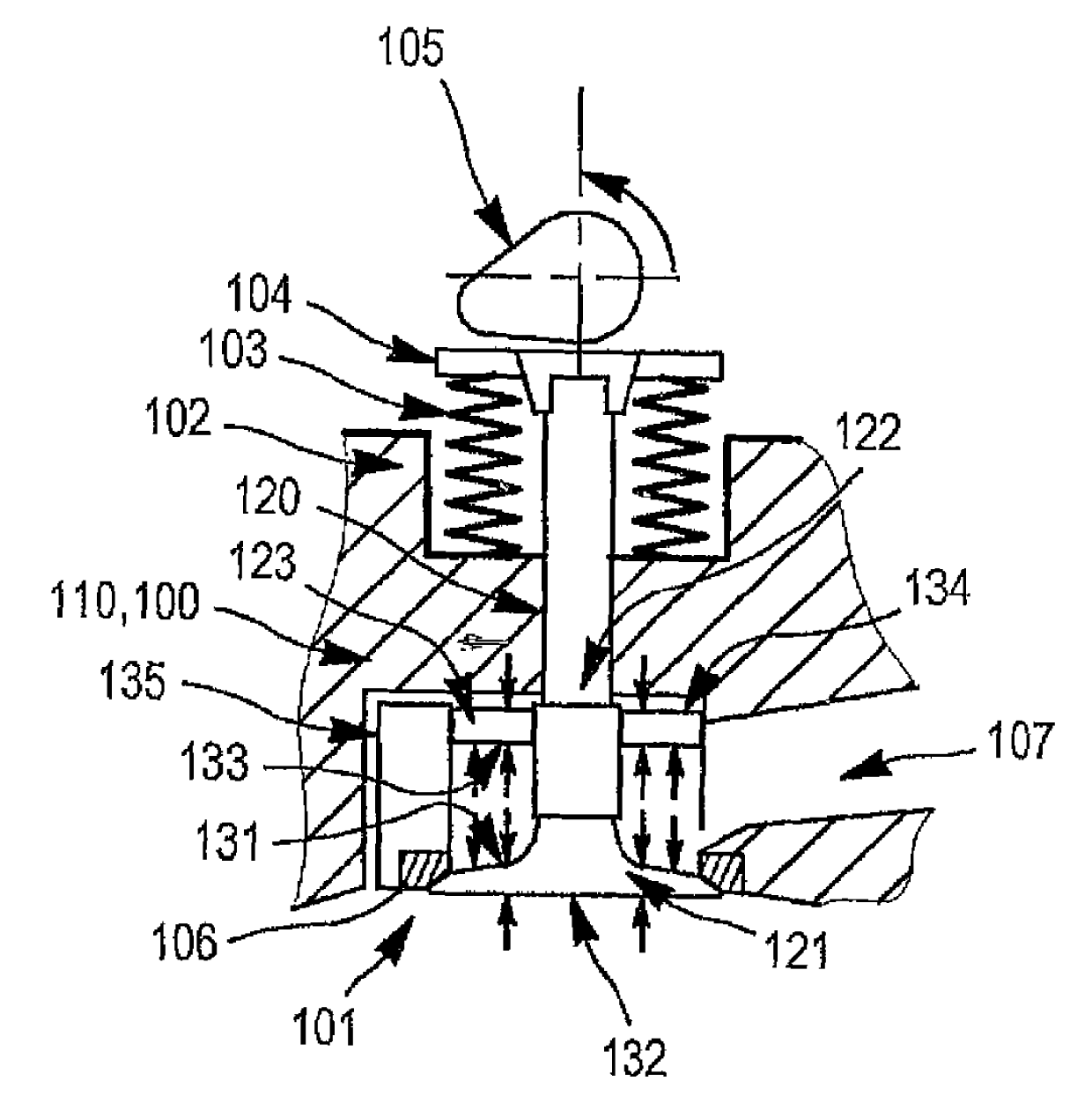

[0050] The mechanical power generation unit shown in FIG. 1 comprises a heat engine 1 and an internal combustion engine 2 . The heat engine includes a circular piston 13 which has reciprocating linear motion and is connected to the power shaft 5 .

[0051] The circular piston 13, viewed from above in FIG. 1 and shown in section in FIG. 10, is mounted in a sealed and axially translational manner in a cylinder 15 having an axis 13a which is parallel to the axis of the circular piston. common. Not shown in FIG. 1 but conventionally, the circular piston 13 is connected with the crankshaft 16 integrated with the power shaft 5 to convert the reciprocating motion of the circular piston into the rotational motion of the crankshaft or vice versa according to the flow direction of mechanical energy. It converts the rotary motion of the crankshaft into the reciprocating motion of the circular piston.

[0052] On the side away from the crankshaft, i.e. above the circular piston in a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com