Liquid immersion cooling device for plastic forming of rotational part and process of liquid immersion cooling device

A technology of plastic forming and cooling device, used in liquid immersion cooling device, cooling and cooling field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

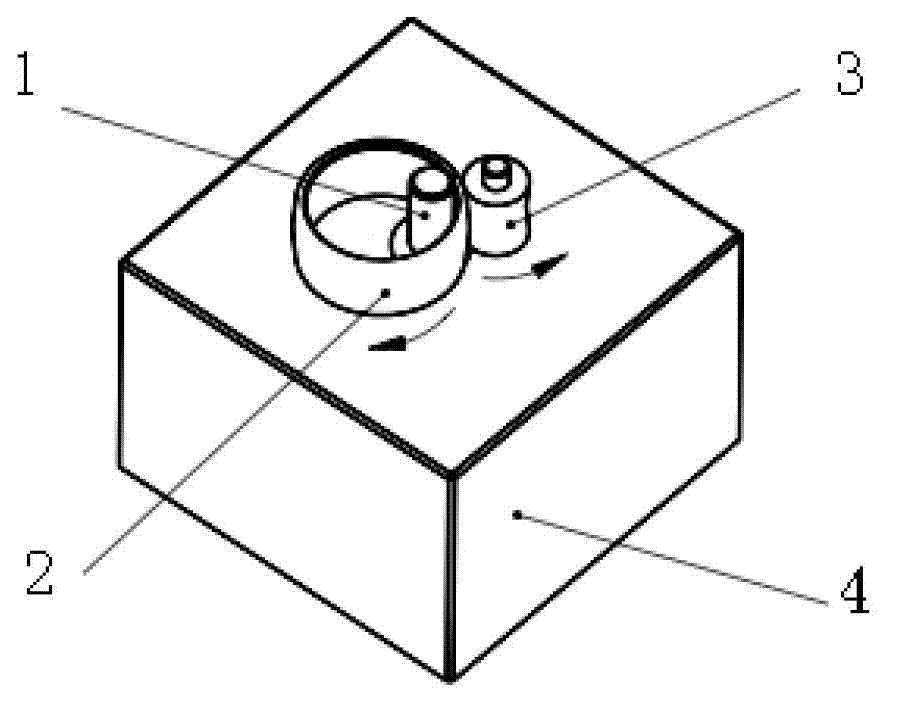

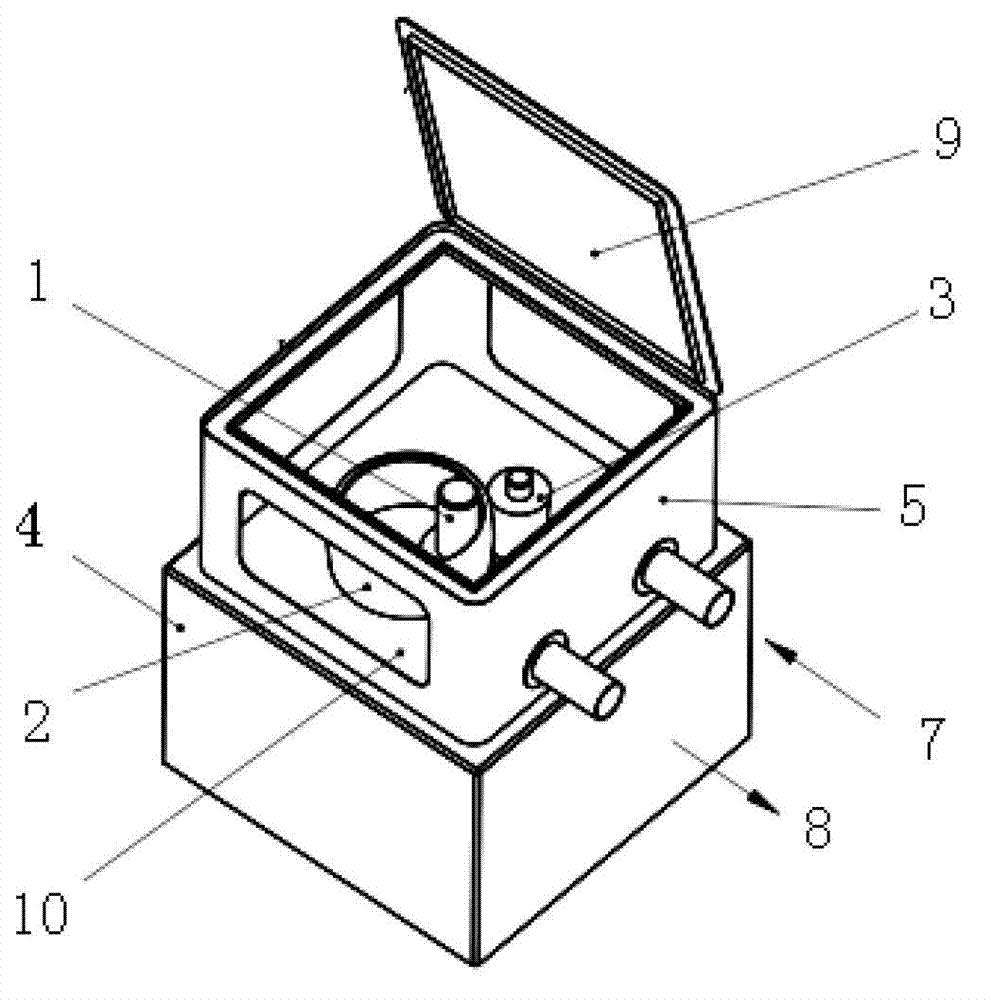

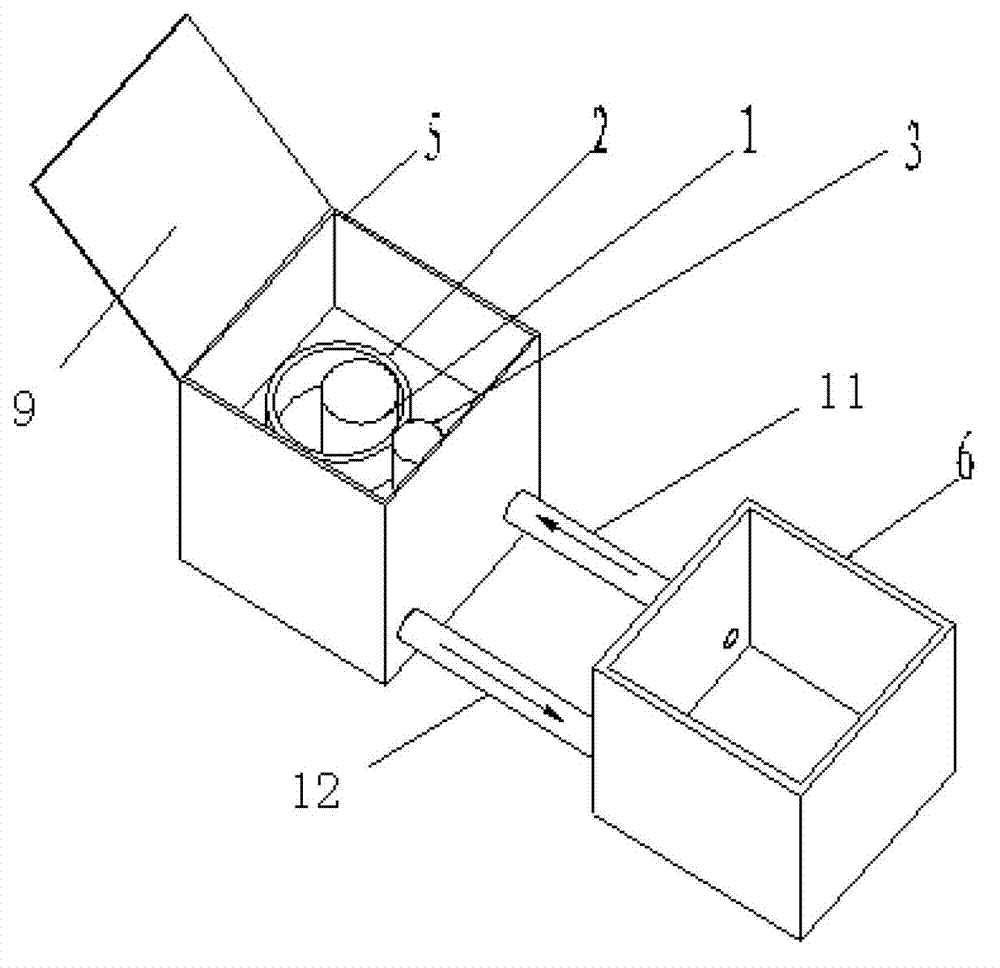

[0022] Taking the typical part of the large deformation rotary body, the expanded rolling blank of the inner and outer rings of SKF railway vehicle bearings as an example, the liquid immersion cooling device and its process proposed by the present invention are explained:

[0023] Liquid immersion cooling device for expanding and rolling blanks of inner and outer rings of SKF railway vehicle bearings (such as figure 2 shown), including the workpiece, the mandrel, the rotary wheel, and the circulating fluid chamber, in which the circulating liquid cavity is filled with cooling liquid, the workpiece, the mandrel, and the rotary wheel are immersed in the cooling liquid, and the liquid circulation inlet and outlet are set on one side of the cavity . The mold consists of a mandrel (that is, the inner wheel) and a rotary wheel (that is, the outer wheel). The liquid circulation inlet and outlet (ie, 7 cooling liquid inlets and 8 high temperature liquid outlets) provided on one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com