Double protection type perforation fluid

A perforating fluid and viscosifying agent technology, applied in the field of perforating fluid, can solve the problems of not being able to prevent water-sensitive damage from oil layer leakage, short time for inorganic salts to stabilize clay, and no consideration of the impact of the environment, so as to facilitate liquid flowback , good protection effect, reduce the effect of water lock damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

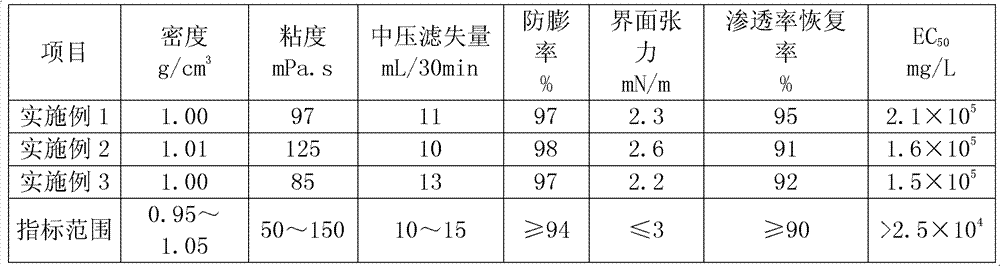

Embodiment 1

[0014] Embodiment 1, preparation of perforating fluid from 25-18 new well in Dagang Oilfield

[0015] The formula is: 80000kg of tap water, 250kg of hydroxypropyl guar gum, 1200kg of modified starch, 2400kg of ammonium chloride, 100kg of diethanolamine laurate, and 100kg of ammonium persulfate capsules.

[0016] The above-mentioned perforating fluid is used for perforating the new well from 25-18 in Dagang Oilfield, and the daily oil production in the early stage of production is more than 20% higher than that of adjacent wells.

Embodiment 2

[0017] Example 2: Preparation of perforating fluid for new well Gang 8-30-1 in Dagang Oilfield

[0018] The formula is: 44000kg of tap water, 220kg of hydroxypropyl guar gum, 350kg of modified starch, 1300kg of ammonium chloride, 25kg of diethanolamine laurate, and 25kg of ammonium persulfate capsules.

[0019] The above-mentioned perforating fluid is used for perforating the new well Gang 8-30-1 in Dagang Oilfield, and the daily oil production in the early stage of production is more than 20% higher than that of adjacent wells.

Embodiment 3

[0020] Embodiment 3: Preparation of perforating fluid from 37-32 new well in Dagang Oilfield

[0021] The formula is: 85000kg of tap water, 170kg of hydroxypropyl guar gum, 1700kg of modified starch, 1700kg of ammonium chloride, 125kg of diethanolamine laurate, and 170kg of ammonium persulfate capsules.

[0022] The above-mentioned perforating fluid was used to perforate new well 37-32 in Dagang oilfield evaluation well, and the highest daily oil production was 4.01t / d at the initial stage of production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com