Production method of composite infrared detector

A technology of infrared detectors and composite materials, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of damage to device performance, many production processes, material performance degradation, etc., to reduce device manufacturing costs, Good process repeatability and high-density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

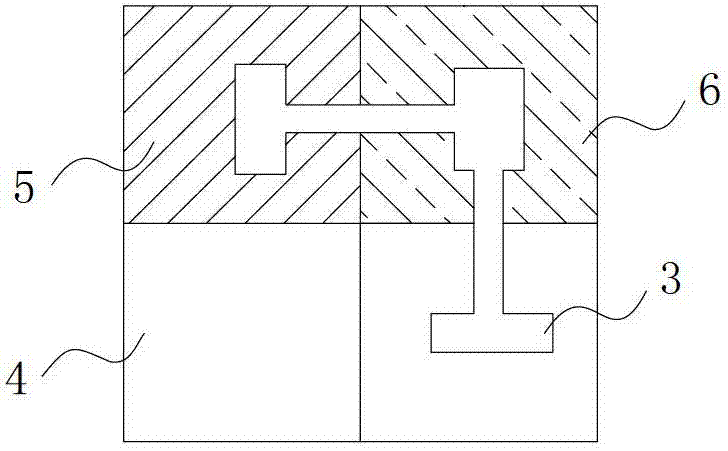

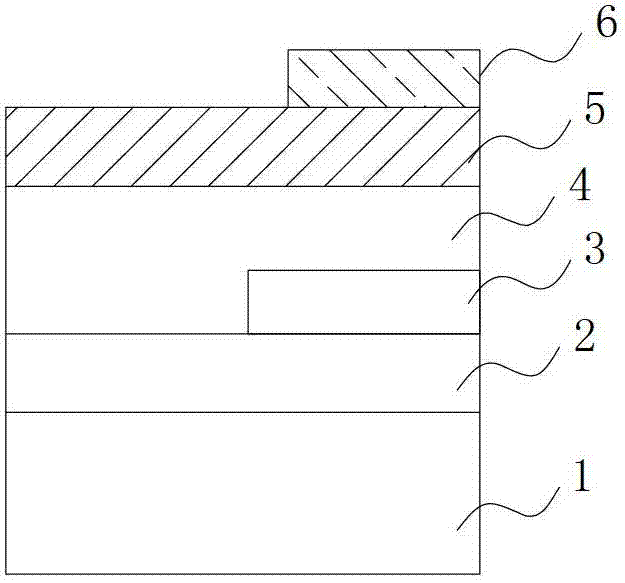

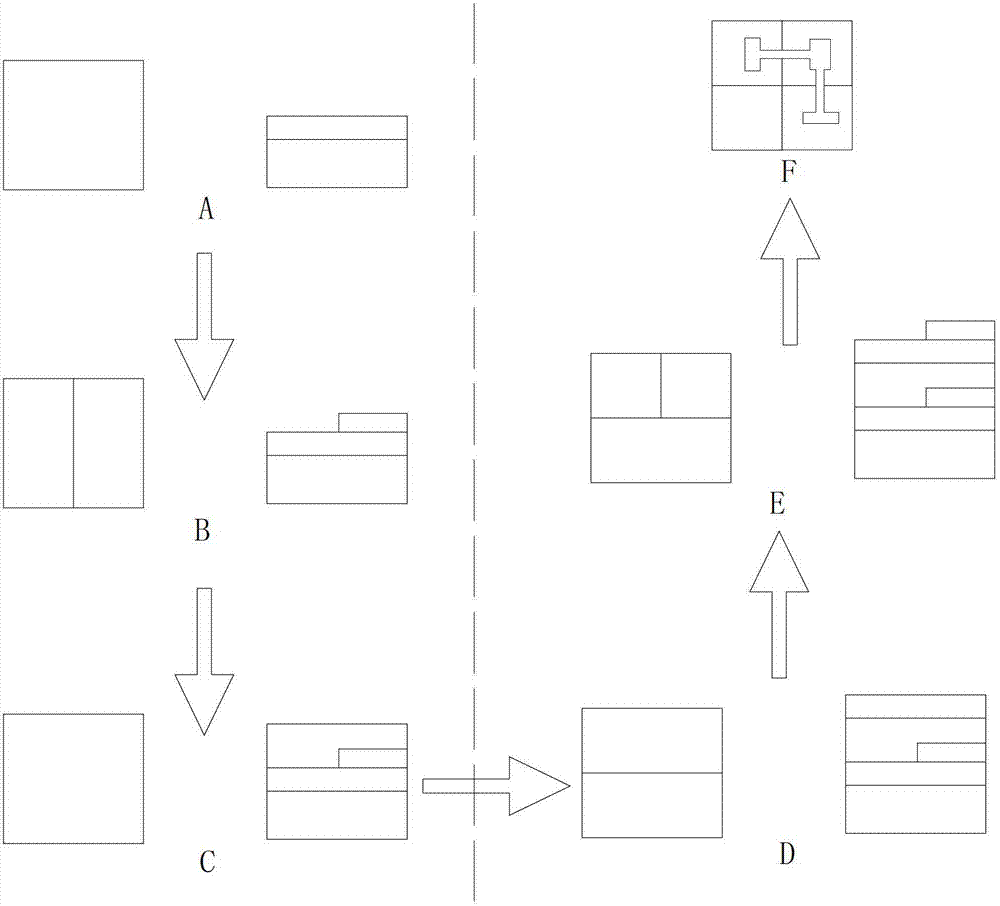

[0029] The composite material infrared detector made by laser etching provided by the present invention is composed of a substrate 1, a heat insulating layer 2, a bottom electrode 3, a heat sensitive film 4, an upper electrode 5 and an infrared absorbing layer 6, as shown in the attached figure 1 shown. It is characterized in that it includes at least the following sequential steps:

[0030] Step 1: Obtain a substrate 1 and a heat insulating layer 2 . The available materials for the substrate 1 are: silicon (Si) single crystal substrate, or strontium titanate (SrTiO 3 ) single crystal substrate, or lanthanum aluminate (LaAlO 3 ) single crystal substrate, or alumina (Al 2 o 3 ) single crystal substrate; the thickness of the substrate 1 is 0.01-10mm.

[0031] For the insulation layer 2, the materials that can be selected are: SiO 2 , or porous SiO 2 , or silicon nitride (Si 3 N 4 ), or PI; the corresponding preparation methods include uniform glue, or sputtering, or pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com