Method for manufacturing front panel of plasma display screen

A technology for a plasma display screen and a production method, which is applied in the field of production of the front panel of a plasma display screen, can solve problems such as poor display quality, large alignment deviation, and poor picture quality, and achieve improved display quality, reduction of alignment deviation, and The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

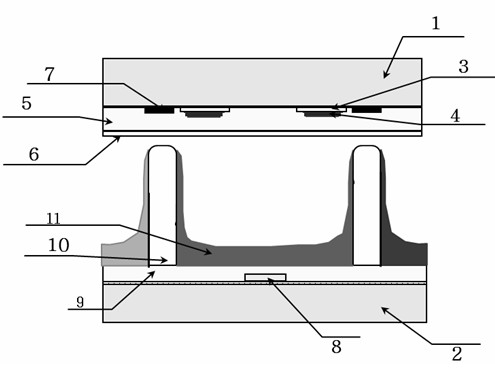

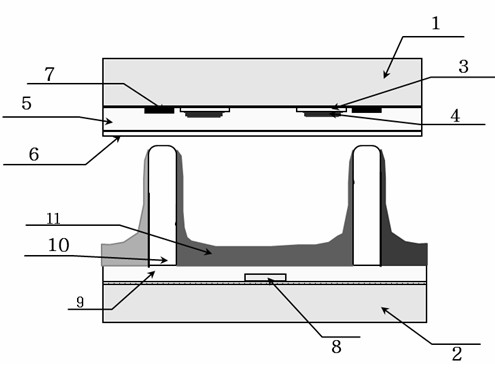

[0024] Such as figure 1 As shown, the plasma display adopts a three-electrode surface discharge structure, including a front panel 1 and a rear panel 2 sealed together with it. The front panel 1 is provided with ITO electrodes 3 and BUS electrodes 4, which form a discharge The display electrode of the present invention has a transparent dielectric layer 5 made on the electrode surface, and a MgO layer 6 is vapor-deposited on the transparent dielectric layer 5 . There are black stripes 7 in the direct non-luminous area of the display electrodes. ADD electrodes 8 perpendicular to the display electrodes are arranged on the rear panel 2, and the ADD electrodes 8 are covered with a rear dielectric layer 9, on which a barrier rib pattern 10 is formed, and a phosphor layer 11 is printed in the barrier rib groove. After the front panel 1 and the rear panel 2 are combined, they are sealed together by low-melting glass powder, and the display screen is filled with working gas Xe+Ne. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com