Automobile exhaust-degrading coiled material used for rapid pavement construction, and production device thereof

A technology for automobile exhaust and production equipment, which is applied in the direction of lamination equipment, layered products, hydraulic material layered products, etc., can solve the problem of complicated construction, inability to collect automobile exhaust gas on the road surface, and inability to fully utilize the photocatalytic degradation of materials. ability and other issues to achieve the effect of improving the photocatalytic degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

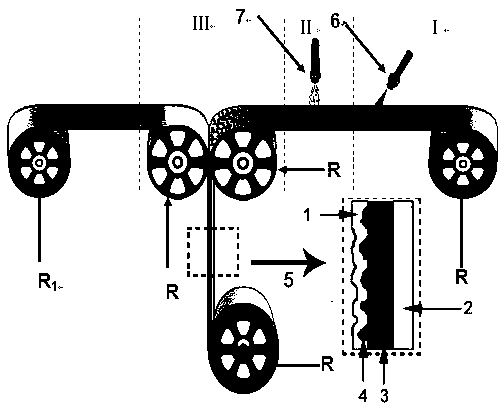

[0025] refer to figure 1 A schematic diagram of the coil structure of the present invention is shown. The roll material 5 is composed of an upper silicone oil surface release paper 1 , an asphalt adhesive layer 3 , degraded particles 4 and a lower silicone oil surface release paper 2 . The lower silicone oil surface release paper 2 is 180g mono-silicon glassine type, and the upper silicone oil surface release paper 1 is 35g mono-silicon ordinary type, with a width of 3.75m and a length of 200m. The asphalt bonding layer 3 is 70# matrix asphalt, with a thickness of 1.2mm.

[0026] refer to figure 1 The schematic diagram of the production device for the roll material of the present invention is shown. roller Provide the transmission power of the release paper 2 on the lower silicone oil surface. When the release paper 2 on the lower silicone oil surface passes through the upstream asphalt spraying area Ⅰ, spray the molten 70# matrix asphalt at the nozzle 6, and the spraying...

Embodiment 2

[0028] refer to figure 1 A schematic diagram of the coil structure of the present invention is shown. The roll material is composed of upper silicone oil surface release paper 1, asphalt adhesive layer 3, degraded particles 4 and lower silicone oil surface release paper 2. The lower silicone oil surface release paper 2 is 100g mono-silicon glassine type, and the upper silicone oil surface release paper 1 is 35g mono-silicon ordinary type, with a width of 7m and a length of 100m. The asphalt bonding layer 3 is emulsified asphalt with a thickness of 0.7mm.

[0029] refer to figure 1 The schematic diagram of the production device for the roll material of the present invention is shown. roller Provide the transmission power of the release paper 2 on the lower silicone oil surface. When the release paper 2 on the lower silicone oil surface passes through the upstream asphalt spraying area Ⅰ, the emulsified asphalt is sprayed at the nozzle 6, and the spraying amount is 2230g / m ...

Embodiment 3

[0031] refer to figure 1 A schematic diagram of the coil structure of the present invention is shown. The roll material is composed of upper silicone oil surface release paper 1, asphalt adhesive layer 3, degraded particles 4 and lower silicone oil surface release paper 2. The lower silicone oil surface release paper 2 is 250g monosilicon glassine type, and the upper silicone oil surface release paper 1 is 100g monosilicon ordinary type, with a width of 3.75m and a length of 100m. The asphalt bonding layer 3 is SBS modified asphalt with a thickness of 2.2 mm.

[0032] refer to figure 1 The schematic diagram of the production device for the roll material of the present invention is shown. roller Provide the transmission power of the release paper 2 on the lower silicone oil surface. When the release paper 2 on the lower silicone oil surface passes through the upstream asphalt spraying zone Ⅰ, spray molten SBS modified asphalt at the nozzle 6, and the spraying amount is 115...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com