High-load-bearing steel wire rope and producing method thereof

A steel wire rope, high load-bearing technology, applied in the field of steel wire rope, can solve the problem that the compression rate of the compacted steel wire rope strands and the internal stress of the rope cannot be well resolved, the fatigue resistance of the steel wire rope is difficult to meet the use requirements, the breaking strength of the steel wire rope, the resistance Fatigue performance and anti-rotation performance did not meet the use requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

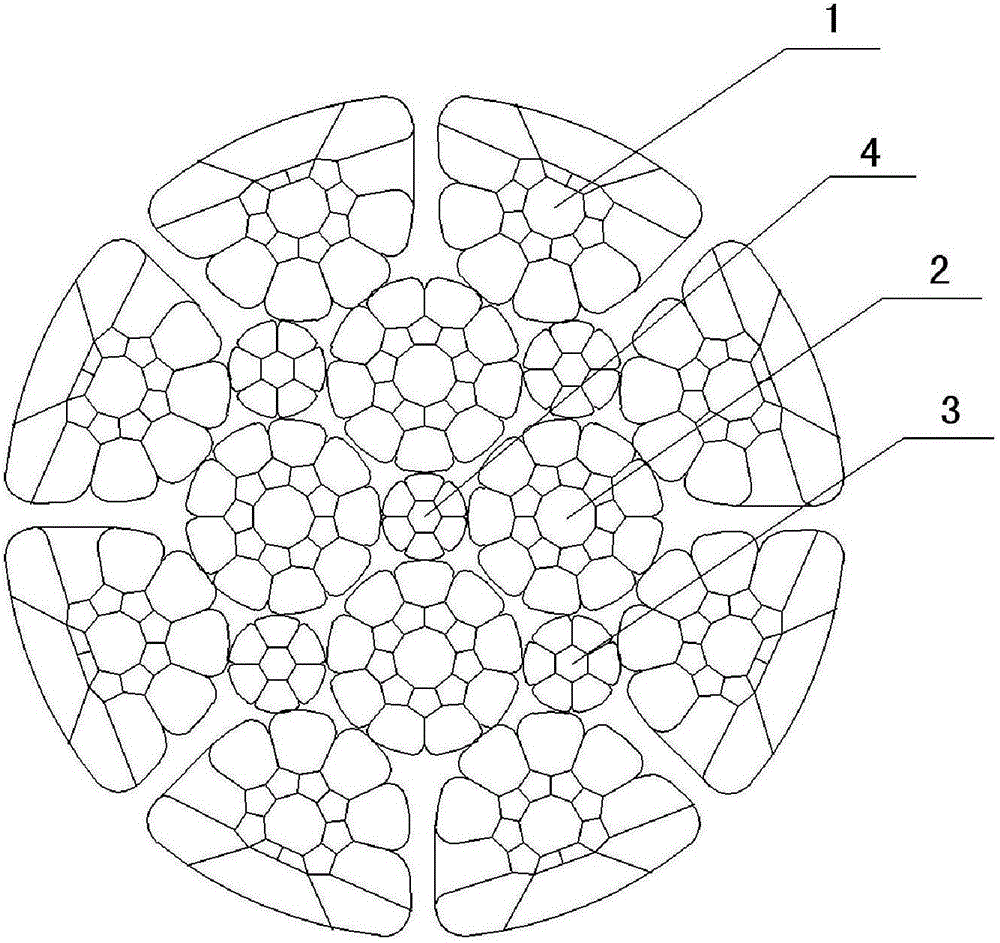

[0016] like figure 1 As shown, a high-load-bearing steel wire rope is formed by twisting eight outer layer strands 1, four filling strands 2, four inner layer strands 3 and one center strand 4. The strands are in surface contact, the outer strand 1, the filling strand 2, and the inner strand 3 are twisted to the left, the center strand 4 is twisted to the right, and the lay length of the outer strand 1 and the inner strand 3 7.5-7.8 times the strand diameter, center strand 4, filler strand 2 lay length 6.4-6.6 strand diameter, outer strand 1, filler strand 2, inner strand 3 wrapping center strand 4, rope twist direction is right lay, The lay length and lay direction of the inner and outer layers are the same, the lay length is 6.3-6.5 times the rope diameter, the inner strand 3 is outside the center strand 4, the outer strand 1 is outside the inner strand 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com