Space truss platform for round building construction and construction method using same

A space truss and construction method technology, applied to the scaffolding supported by the house structure, building structure, construction, etc., can solve the problems of poor integrity, poor economic benefits, and high cost of plane trusses, and achieve easy installation and disassembly, and save costs , the effect of saving working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0063] (1) The structure of the space truss platform.

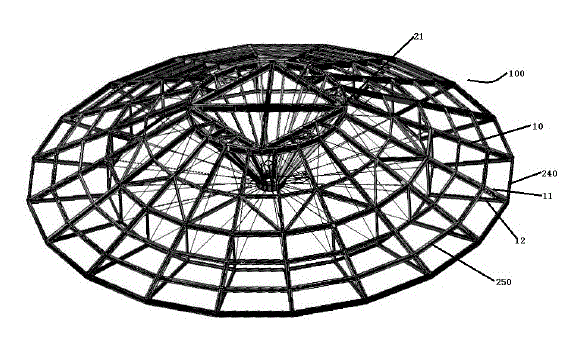

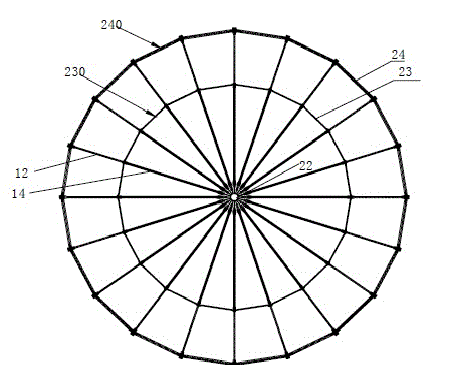

[0064] Such as figure 1 As shown, the space truss platform 100 used for the construction of circular structures uses a plurality of steel frame units 10 arranged radially along the truncated cone through connectors 20 to be evenly arranged around the circumferential direction and spliced into a stable truncated conical space structure. .

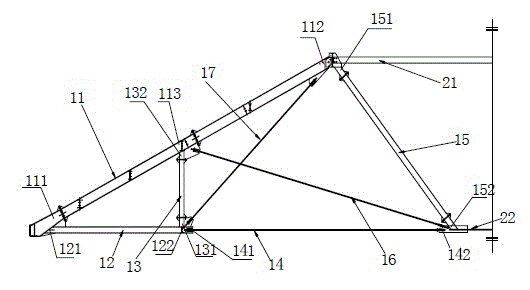

[0065] Among them, such as figure 2 As shown, each steel frame unit 10 includes the upper chord strut 11 on the side of the truncated conical space structure, the lower chord tie rod 12 on the bottom surface of the truncated conical space structure, the first shaped steel web bar 13 and the second The second-shaped steel web bar 15, and the first steel prestressed tie rod 14, the second steel bar prestressed tie rod 16, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com