Deep-sea sediment continuous pressure maintaining coring submarine drilling machine and operation method

A deep-sea sediment and core drilling technology, which is applied in the field of deep-sea exploration technology and marine engineering, can solve the problems of low-disturbance drilling of seabed sediment, high-efficiency sediment exploration and sampling operations, and core exploration and investigation operations. , to achieve the effect of light weight, compact structure and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

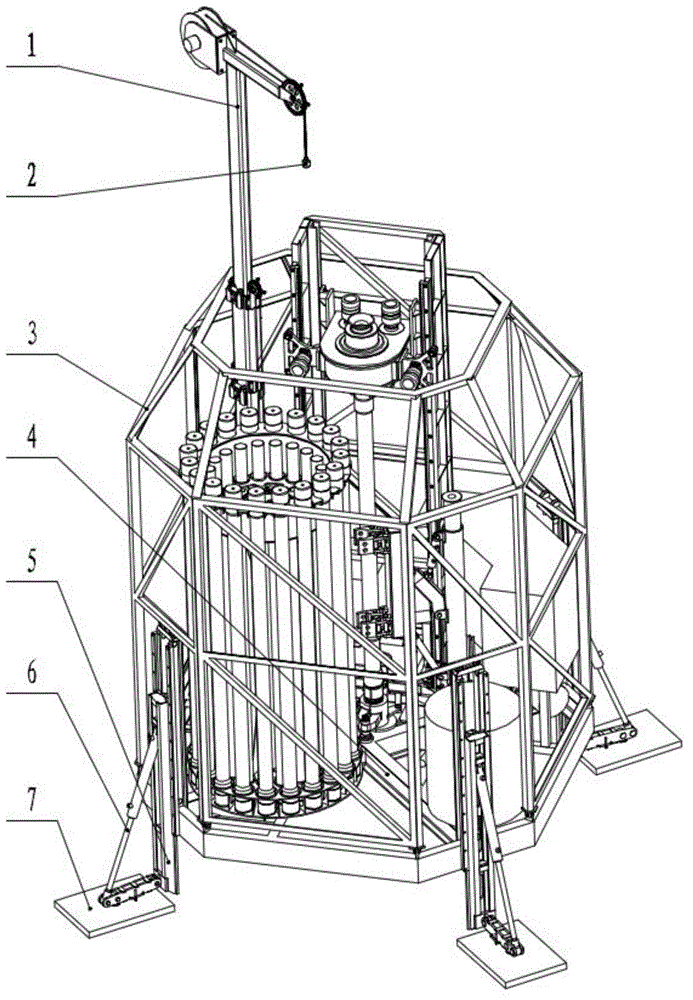

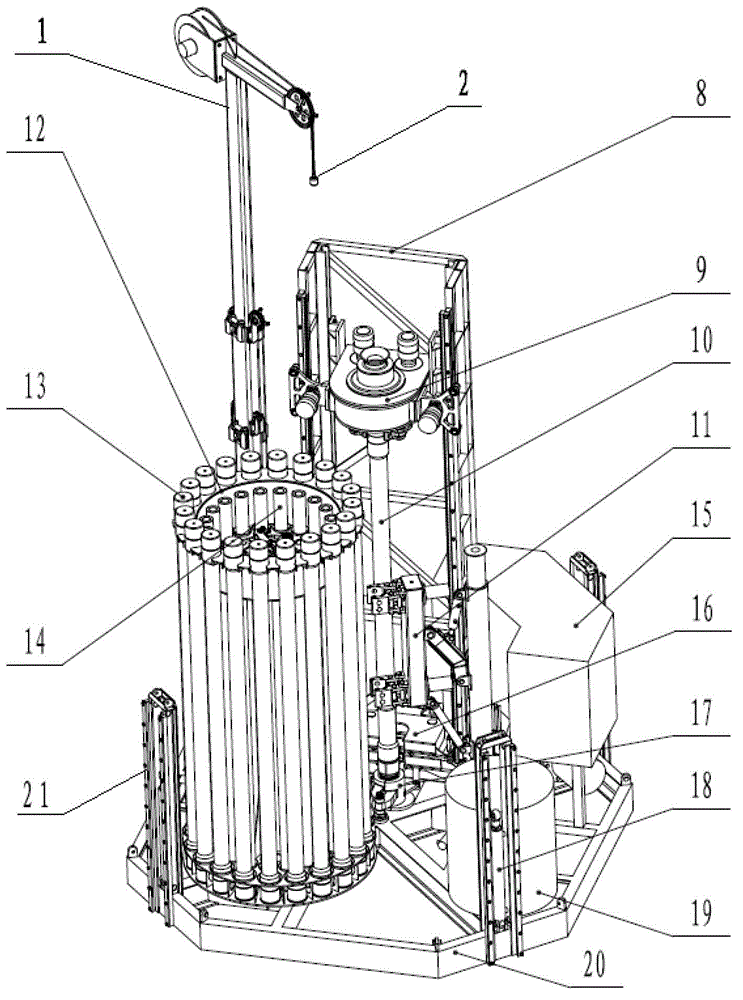

[0041] refer to figure 1 , figure 2 , the structure of the continuous pressure-holding and coring subsea drilling rig for deep-sea sediments of the present invention includes a base 20 on which a sampling pipe manipulator 1, a plurality of pile legs 5, a derrick 8, a drill pipe manipulator 11, and a pipe rack are respectively arranged. 12. Hydraulic system 15, hydraulic buckle clamp 16, drill pipe holder 17, underwater control system 19, these components together constitute the main body 4 of the drilling rig,

[0042] The main frame 3 is fixedly installed on the base 20, the main frame 3 is a detachable frame structure, used to surround the above-mentioned drilling rig main body 4, the lower end of the main frame 3 is connected to the upper surface of the base 20 through ear pulls and pin shafts Fixed connection, the upper end of the main frame 3 is connected with the armored suspension cable of the scientific research ship ( figure 1 not shown), the main frame 3 can bear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com