Moving grate drying bed-circulating fluidized bed boiler-compounded incineration equipment

A circulating fluidized bed and movable grate technology, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of high treatment cost, low incineration efficiency, insufficient combustion, etc., and achieve good gas-solid mixing, Enhance drying effect, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

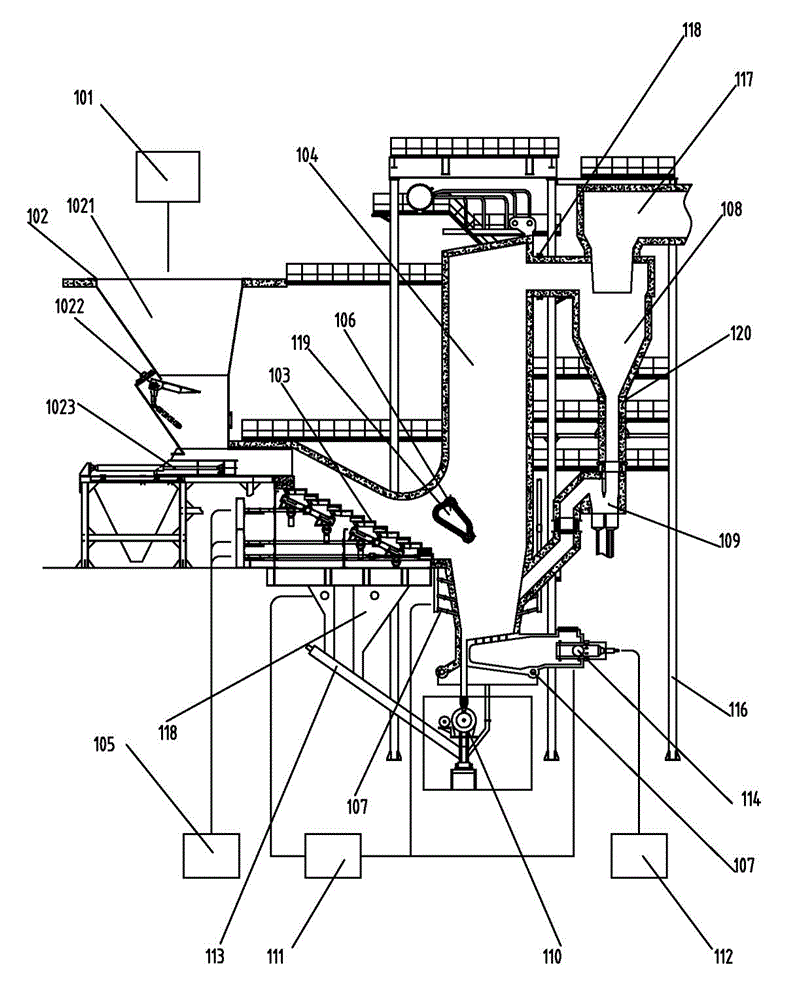

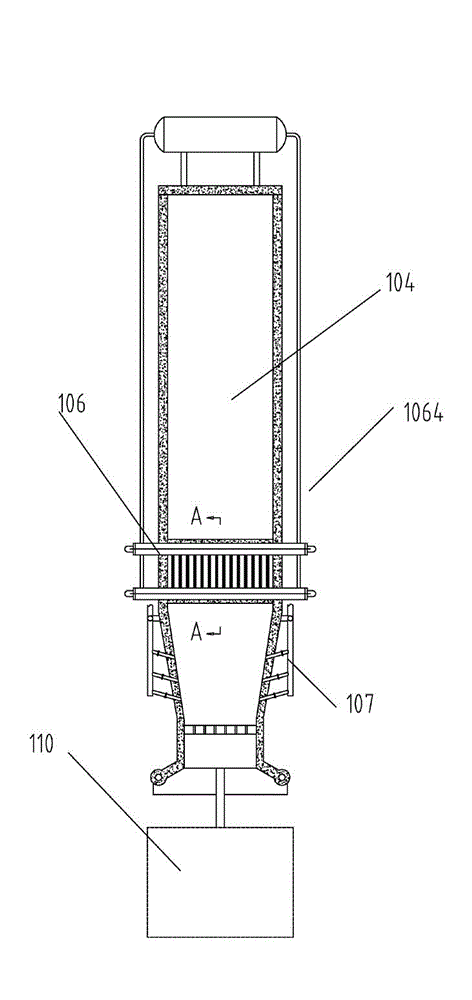

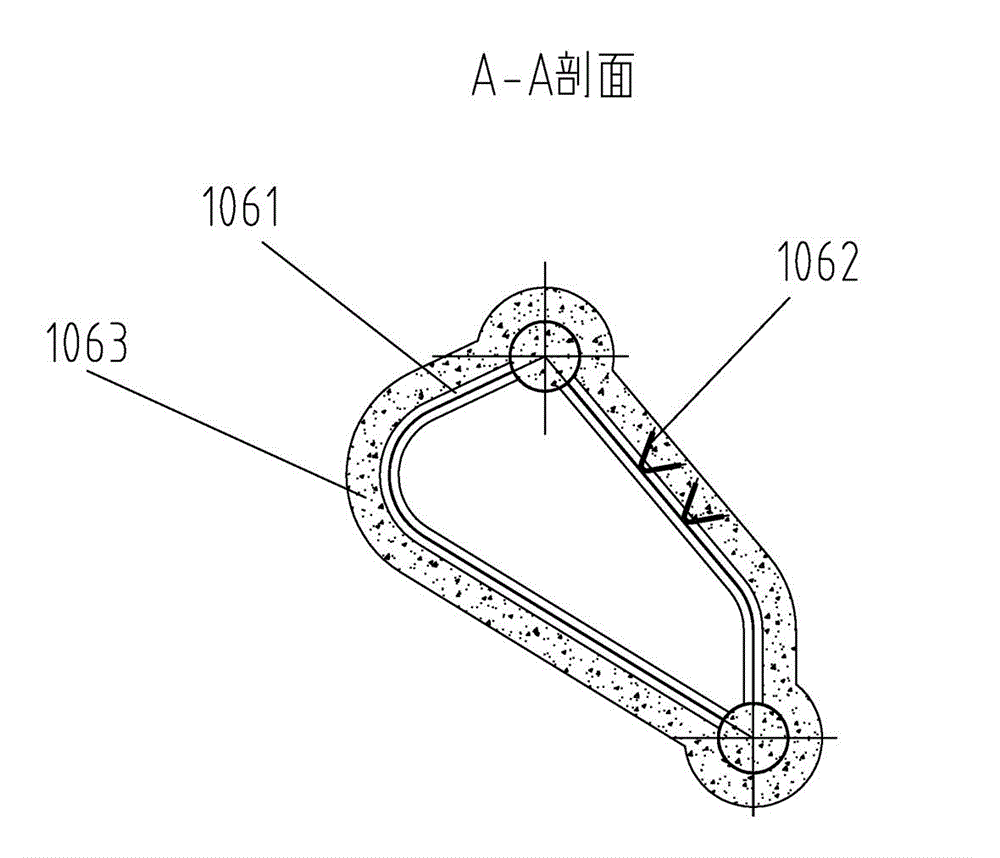

[0021] Combine now Figure 1~Figure 3 Further describe in detail the preferred implementation technical scheme of the movable grate-circulating fluidized bed composite incineration equipment of the present invention: a movable grate-circulating fluidized bed composite incineration equipment, including a pre-drying granulation system 101, Material system 102, active grate drying bed 103, circulating fluidized bed boiler 104, hydraulic device 105, diversion device 106, air distribution device 107, cyclone separator 108, feeding device 109, slag removal device 110, gas supply system 111, oil supply system 112, ash release channel 113, starting burner 114, steel structure 116 and corresponding supporting flue gas outlet 117 and ash fall pipe (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com