Special-shaped crucible for steel-making bottom blowing and preparation method thereof

A technology for special-shaped crucibles and manufacturing methods, which is applied in the direction of crucible furnaces, furnace types, furnaces, etc., and can solve problems such as difficult experiments, poor ventilation efficiency, and difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A special-shaped crucible for bottom blowing in steelmaking.

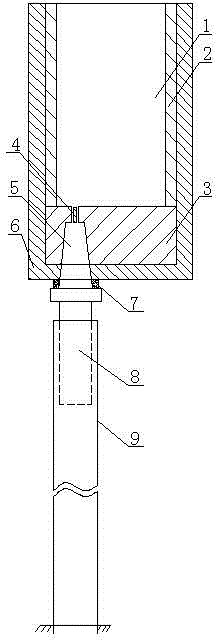

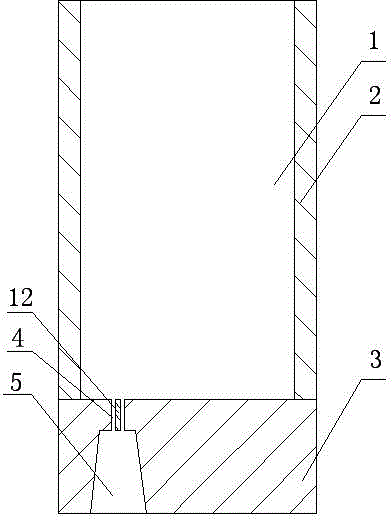

[0041] For the structure of special-shaped crucibles for bottom blowing in steelmaking, see figure 1 , the special-shaped crucible is divided into upper, middle and lower parts, the upper part is a hollow cylindrical cavity 1, which is used to hold molten steel for smelting; the middle part is a partition layer, called the air-permeable layer 2, and the vent holes are distributed eccentrically; the lower part is the connecting layer 3 . The connecting layer 3 is provided with a tapered hole 5 , and the tapered hole 5 communicates with the ventilation hole 4 . See figure 1 , the tapered hole 5 is small at the top and large at the bottom, with a taper of 3-5°. The tapered hole 5 is aligned with the ventilation hole 4, and is used for connecting the blowing pipeline. The number, size and distribution position of the bottom blowing air holes of special-shaped crucible are related to the require...

Embodiment 2

[0043] Embodiment 2: A method for manufacturing a special-shaped crucible for bottom blowing in steelmaking.

[0044] A method for manufacturing a special-shaped crucible for bottom blowing in steelmaking. The equipment used in the method includes a graphite cylinder 6, a graphite core 10, and a conical plug 11. The steps are divided into two parts: knotting and firing:

[0045] tie

[0046]Preparation of ramming material: take magnesia and boric acid powder as raw materials. The main chemical components of magnesia and boric acid are shown in Table 1. By weight, boric acid is 3% to 5%, and the rest is magnesia. Repeatedly mix magnesia and boric acid powder to form a uniform ramming material for later use. The MgO content in the ramming material is greater than 98%.

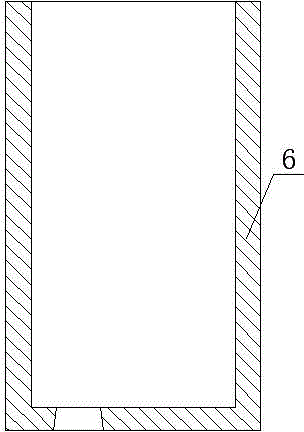

[0047] Then the graphite mold used for sintering is assembled, and the structure of the graphite mold is as follows Figure 3-Figure 5 As shown, it is composed of graphite cylinder 6, graphite core 10 and taper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap