Punching type macadamia nut husk crusher

A punching and shell breaking machine technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of loss of nuts, slow development, low rate of whole kernels, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

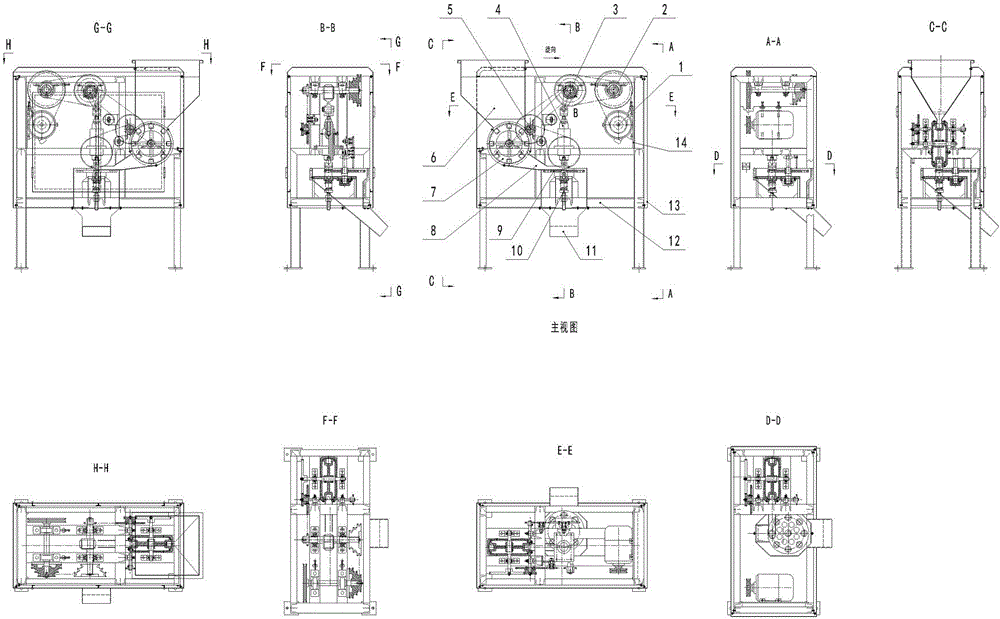

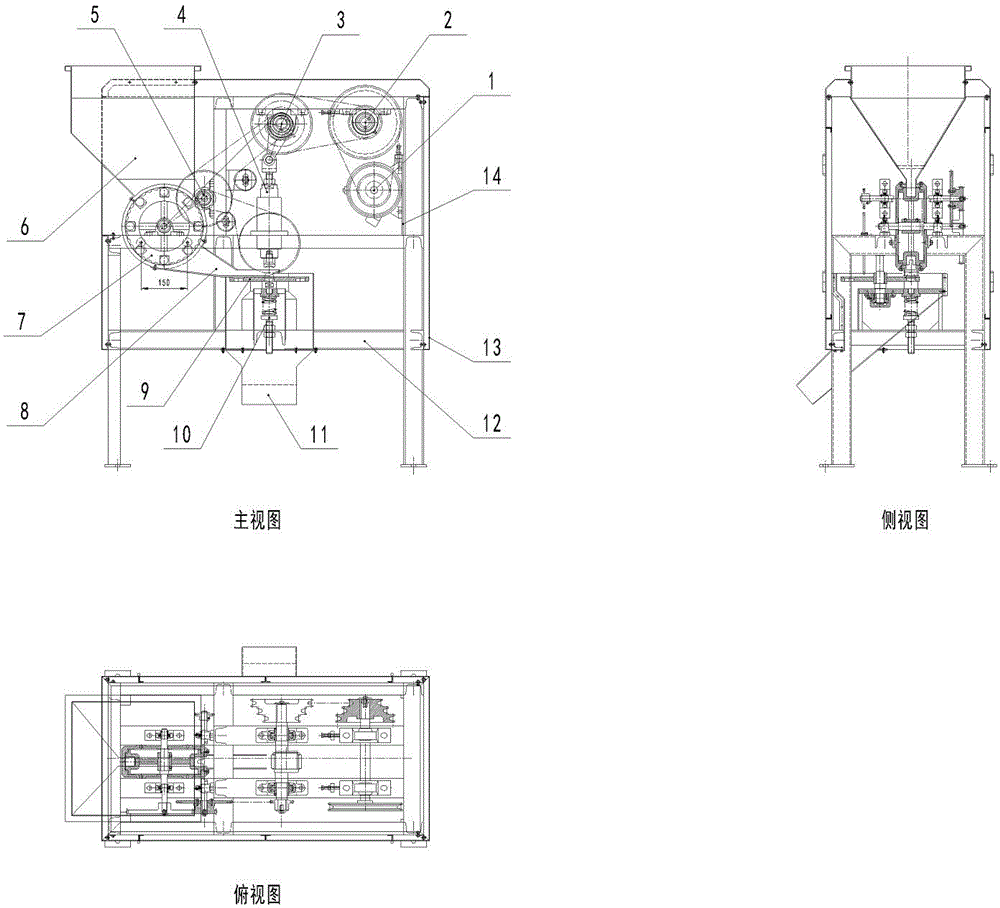

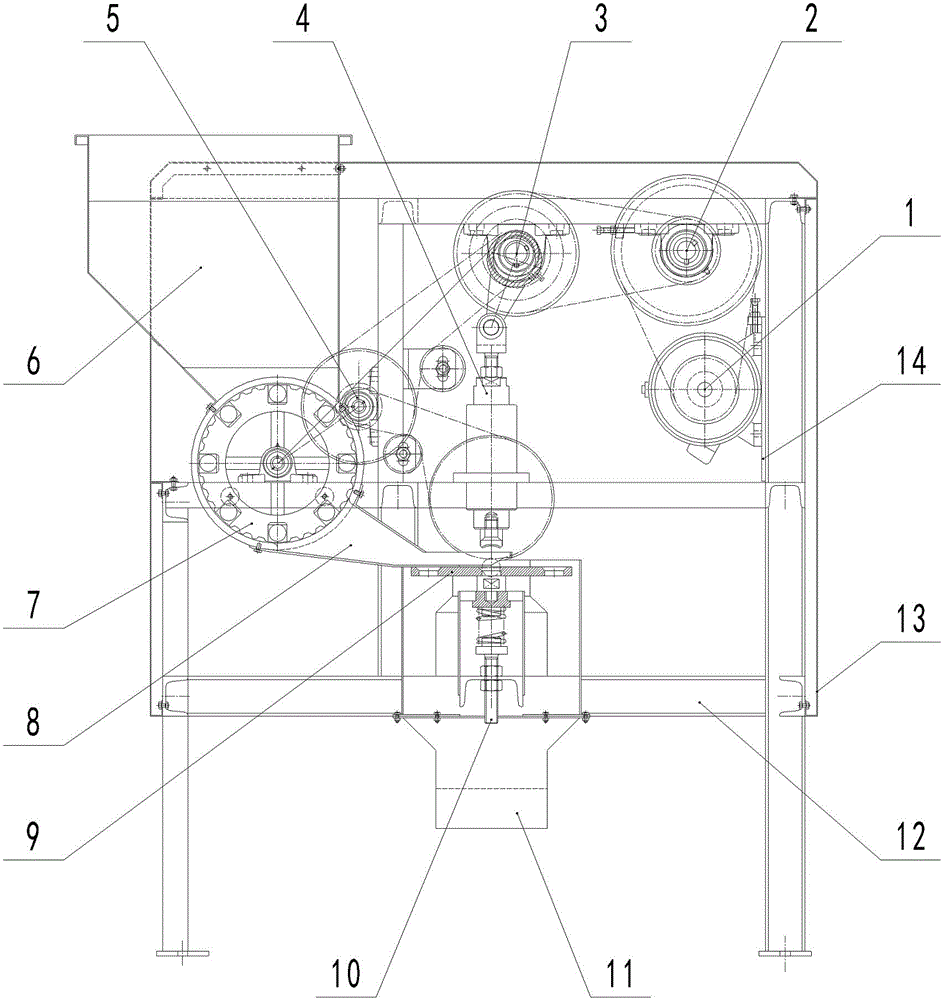

[0048] Below in conjunction with accompanying drawing, technical solution of the present invention will be further described:

[0049] Such as figure 1 , figure 2 , image 3The stamping type macadamia nut shell breaking machine shown is mainly composed of a driving mechanism (1), a primary speed change mechanism (2), a secondary speed change mechanism (3), a crank slider stamping and cutting mechanism (4), a three-stage speed change mechanism ( 5), feed hopper (6), quantitative feeding mechanism (7), material guide groove (8), material positioning turntable mechanism (9), material support base (10), discharge hopper (11), frame (12 ), casing (13), motor adjustment seat (14) constitute.

[0050] The working principle and working process of the stamping macadamia nut shelling machine have four core contents and processes: power drive, quantitative feeding, crank slider stamping and cutting, material positioning and shell breaking discharge.

[0051] The driving mechanism (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com