Grinding component for steam trap in nuclear power plant

A technology for steam traps and nuclear power plants, which is applied in the field of grinding components of steam traps in nuclear power plants. It can solve problems such as uneven grinding force, time-consuming, and deformation of sealing planes, and achieve the effects of simple installation and disassembly, saving working time and saving human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

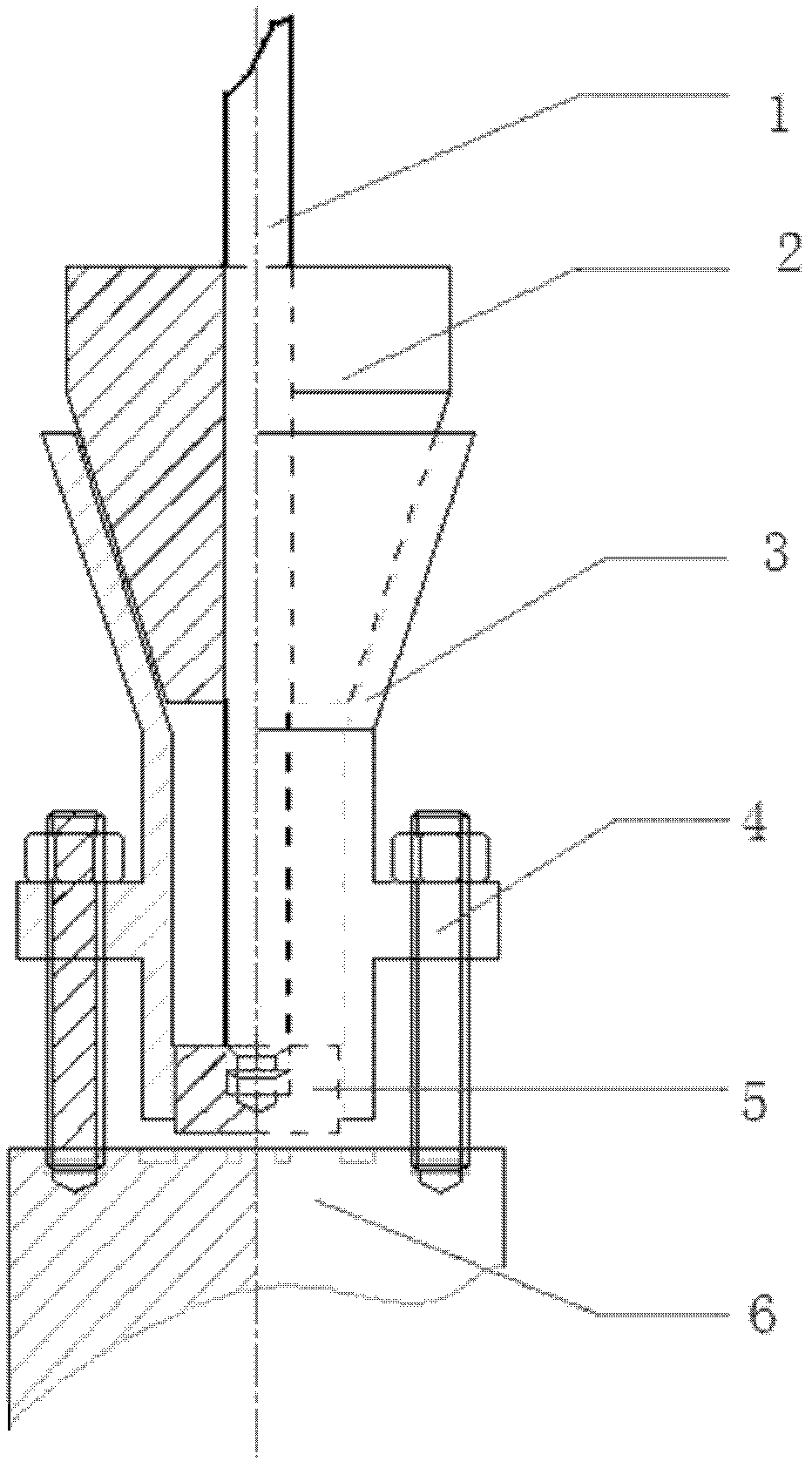

[0018] Such as figure 1 As shown, a nuclear power plant steam trap grinding assembly includes a fixed support device 3, a nylon centering sleeve 2, a grinding disc 5, a grinder grinding rod 1 and a bolt 4, and the upper part of the fixed support device 3 is in the shape of an inverted cone. The lower part is in the shape of a hollow cylinder, and the nylon centering sleeve 2 is in the shape of a funnel, and is arranged in the upper part of the inverted cone of the fixed support device 3. The grinding machine will have a certain degree of shaking and off-target phenomena during the grinding process, which is perfect The centering sleeve can play a decisive role in preventing the above phenomenon in the whole grinding. Nylon material has high mechanical strength, heat resistance, wear resistance, self-lubrication, shock absorption and noise reduction.

[0019] The grinding disc 5 is a brass grinding disc, which is arranged at the lower end of the hollow cylinder of the fixed su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com