Electro-hydraulic jet printing device of metal micro-nanometer structure

A micro-nano structure, electro-hydraulic technology, applied in printing, printing process, printing of special varieties of printed matter, etc., can solve the problems that limit the precise positioning and deposition of micro-nano structure, popularization and application, and achieve good stability and continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

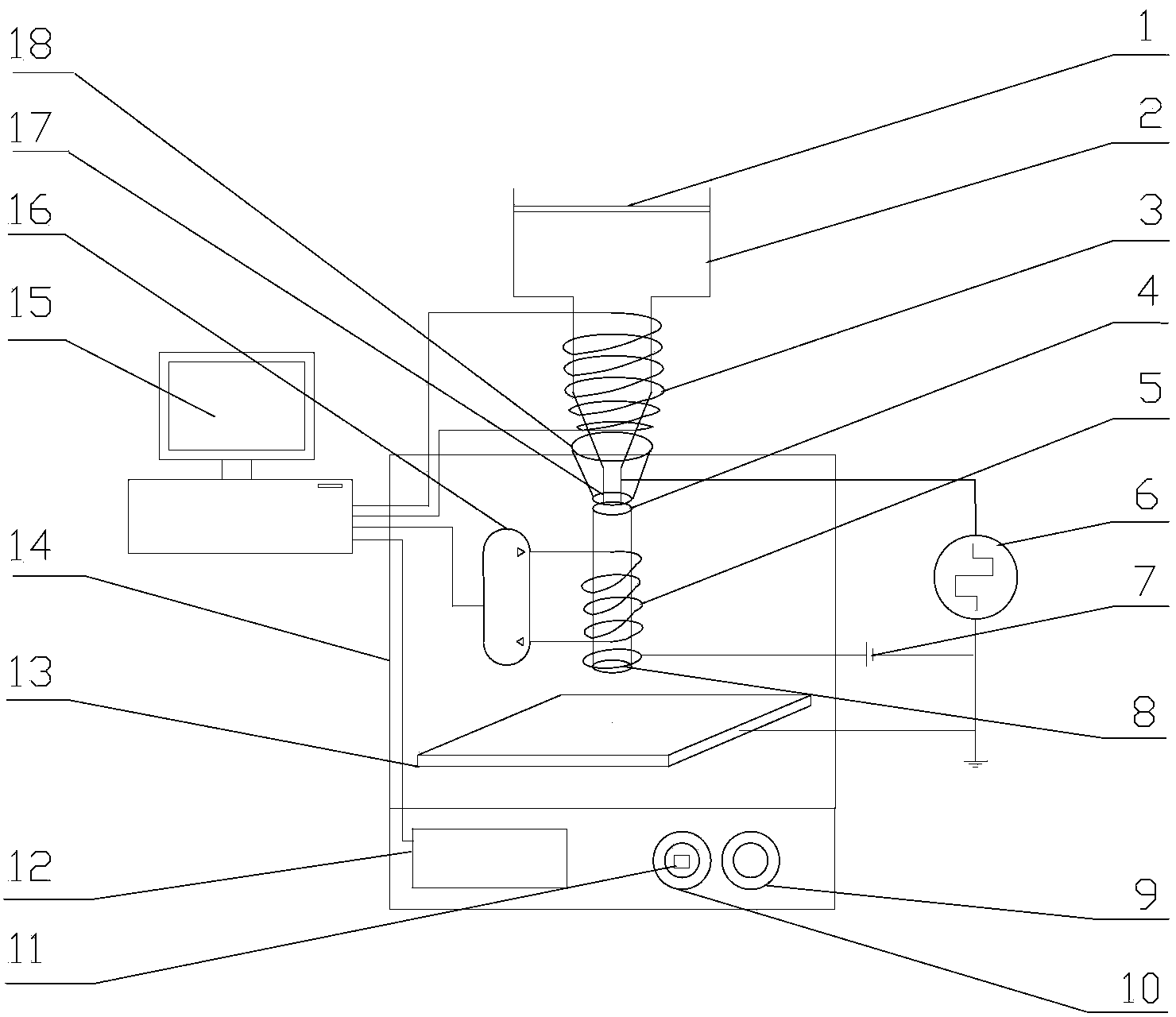

[0023] see figure 1 , the embodiment of the present invention is provided with a pressure controller 1, a feed tank 2, a heater 3, an insulating sleeve 4, a temperature control condenser 5, a high-voltage pulse power supply 6, an auxiliary power supply 7, a restraint electrode ring 8, and an air extraction interface 9 , air inlet port 10, pressure valve 11, pressure gauge 12, collecting plate 13, protective cover 14, computer 15, temperature controller 16, nozzle 17 and annular vent 18;

[0024]The feed tank 2 is set under the pressure controller 1, the lower part of the feed tank 2 is provided with a feed channel, the feed channel is made of a thermal conductor, the heater 3 is located on the periphery of the feed channel, and the nozzle 17 is located in the feed channel At the lower end, the insulating sleeve 4 is set directly below the nozzle 17, and the temperature control condensation pipe 5 is disposed on the periphery of the insulation sleeve 4. The control end of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com