Integration drive control device for supercapacitor energy storage type elevator

A capacitive energy storage, super capacitor technology, applied in the direction of elevator energy efficiency, transportation and packaging, sustainable buildings, etc., can solve problems such as reducing failure risk, poor coordination, signal interference, etc., saving hardware resources and reducing debugging. Difficulty, the effect of simplifying the software structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

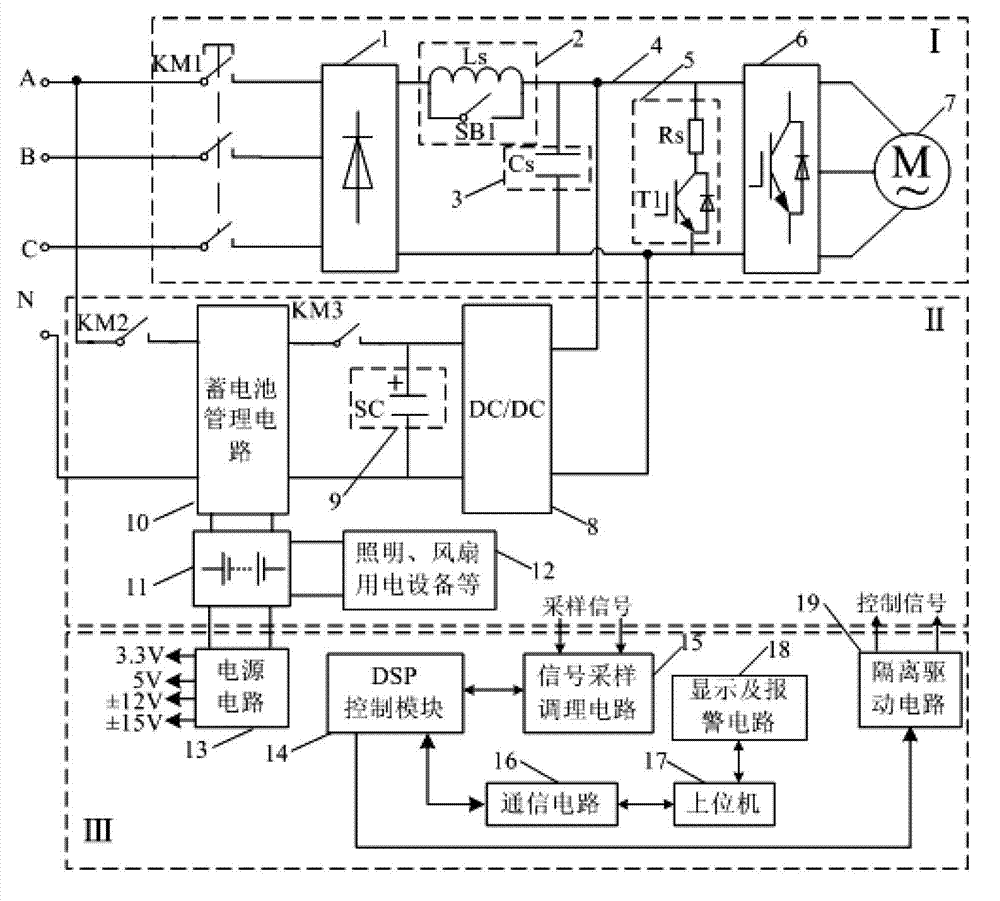

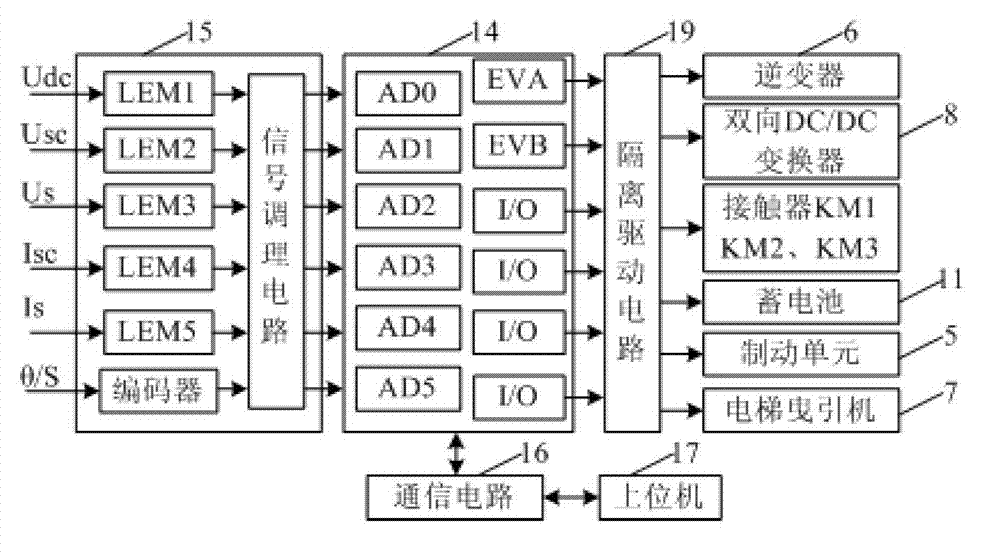

[0030] The supercapacitor energy storage type elevator integrated drive control device of the present invention is composed of an elevator operation control subsystem and an elevator energy-saving control subsystem, and the specific implementation plan combines figure 1 illustrate.

[0031] The main circuit of the supercapacitor energy storage elevator integrated drive control device is as follows: figure 1 As shown, the main circuit structure of the elevator operation control subsystem is shown in the module I unit, which consists of the first contactor KM1, the uncontrollable rectifier 1, the buffer circuit 2, the filter capacitor 3, the DC bus 4, the braking unit 5, the inverter device 6 and elevator traction machine 7.

[0032] Specifically: the main circuit part of the elevator operation control subsystem is first connected to the external three-phase power grid through the first contactor KM1, the three-phase alternating current is rectified by the uncontrollable rectif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com