Laminating type micro-convex-table array type micro-reactor for steam reforming of methanol

A technology of reforming hydrogen production and micro-reactors, which is applied in the fields of hydrogen, chemical instruments and methods, and inorganic chemistry. Heat and mass transfer performance, easy disassembly and catalyst loading, and the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with drawings and embodiments.

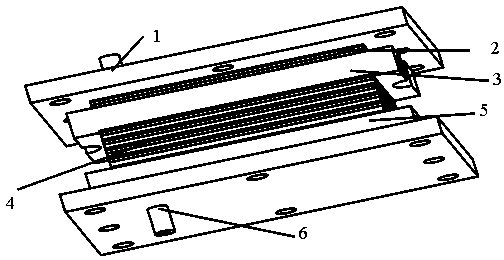

[0039] Such as figure 1 As shown, the present invention includes an upper cover plate assembly 1, an evaporation unit 2, a first heating plate 3, a reforming reaction hydrogen production component 4, a second heating plate 5 and a lower cover plate assembly 6 from top to bottom; wherein:

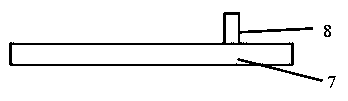

[0040] 1) Top cover assembly 1, such as figure 2 As shown: it includes an upper cover plate 7 with threaded holes around the rectangular structure and an inlet stainless steel pipe 8; the inlet stainless steel pipe 8 is connected to the fluid inlet hole on one side of the upper cover plate 7.

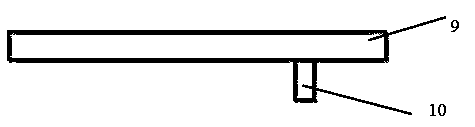

[0041] 2) Lower cover assembly 6, such as image 3 As shown: the lower cover plate 9 and the outlet stainless steel pipe 10 including a rectangular structure with threaded holes around it; Tube 8 corresponds.

[0042] 3) Evaporation unit 2, such as Figure 4 As shown: two evaporating plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com