Epoxy resin modified waterborne hyperbranched polyurethane and preparation method thereof

A hyperbranched polyurethane and epoxy resin technology, applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, adhesive types, etc., can solve the problems of insufficient stability of the emulsion, cumbersome steps, and easy cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] The preparation method of epoxy resin modified waterborne hyperbranched polyurethane of the present invention, concrete steps are as follows:

[0085] 1) The organic acid (a) containing one carboxyl group and two hydroxyl groups and the alcohol (b) containing multiple hydroxyl groups are reacted at a certain reaction temperature (such as 140-160 ° C) for a period of time (such as 8-24 hours), under vacuum conditions (such as below 740mmHg), the molar ratio between (a) and (b) used is 12 / 1-4 / 1, thereby forming a large amount of hydroxyl-terminated reaction intermediates (referred to as A1 , namely the hyperbranched polyester A-(OH) of the present invention n );

[0086] Wherein, used (a), its structure is as follows:

[0087]

[0088] Among them, R 5 Can be:

[0089]

[0090]Wherein, m is an integer ≥ 1 (preferably an integer of 1-10).

[0091] (b) used may be:

[0092] ethylene glycol, diethylene glycol,

[0093] Glycerol, Trimethylolpropane,

[00...

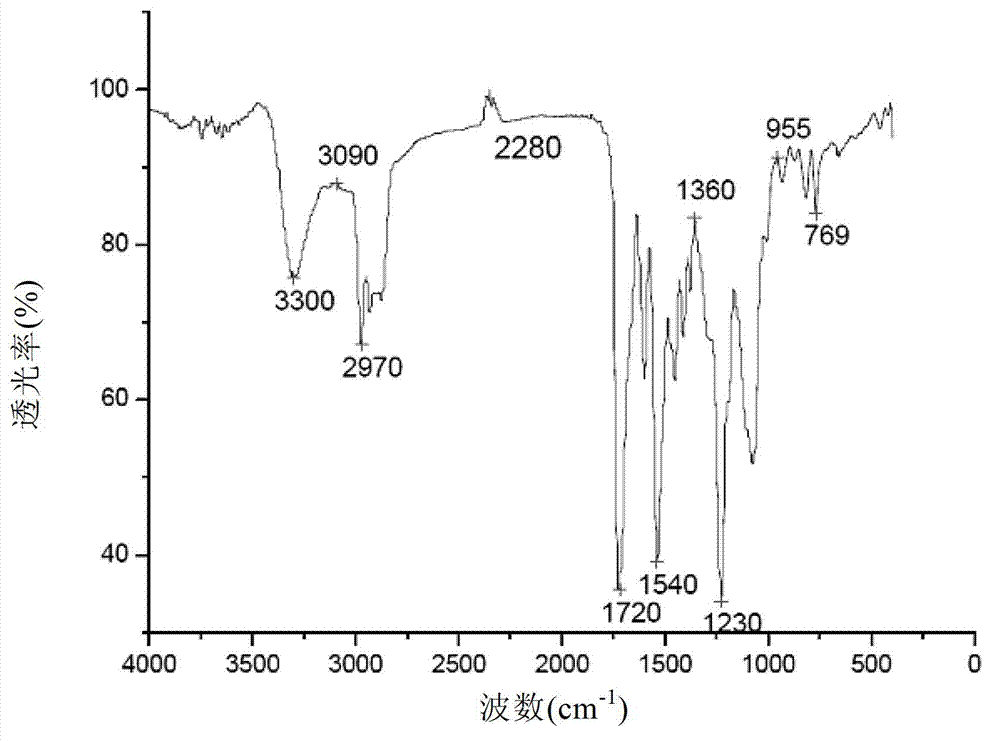

Embodiment 1

[0142] 1.1 Preparation of epoxy resin modified waterborne hyperbranched polyurethane 1

[0143] 1) Add 13.6g (0.1mol) of pentaerythritol and 53.64g (0.4mol) of dimethylolpropionic acid (DMPA) in a four-necked flask equipped with mechanical stirring, a thermometer, and a condenser tube. (740mmHg), react at 140-160°C for 2.5h to obtain a transparent yellowish liquid;

[0144] Then add 107.28g (0.8mol) DMPA to the transparent yellowish liquid, and react at 140-160°C under vacuum conditions (below 740mmHg), until the acid value of the resin is measured to be less than 20mg KOH / g, and the reaction is terminated , discharging, cooling to obtain light yellow transparent or translucent solid, denoted as A1-1 (the molar ratio of pentaerythritol and dimethylolpropionic acid is 1 / 12).

[0145] 2) Dissolve 18.94g of A1-1 (0.0121mol) in 50g of N-methylpyrrolidone, add 8.57g (0.085mol) of succinic anhydride, and react at 100°C for 36 hours to obtain a light yellow transparent liquid, which...

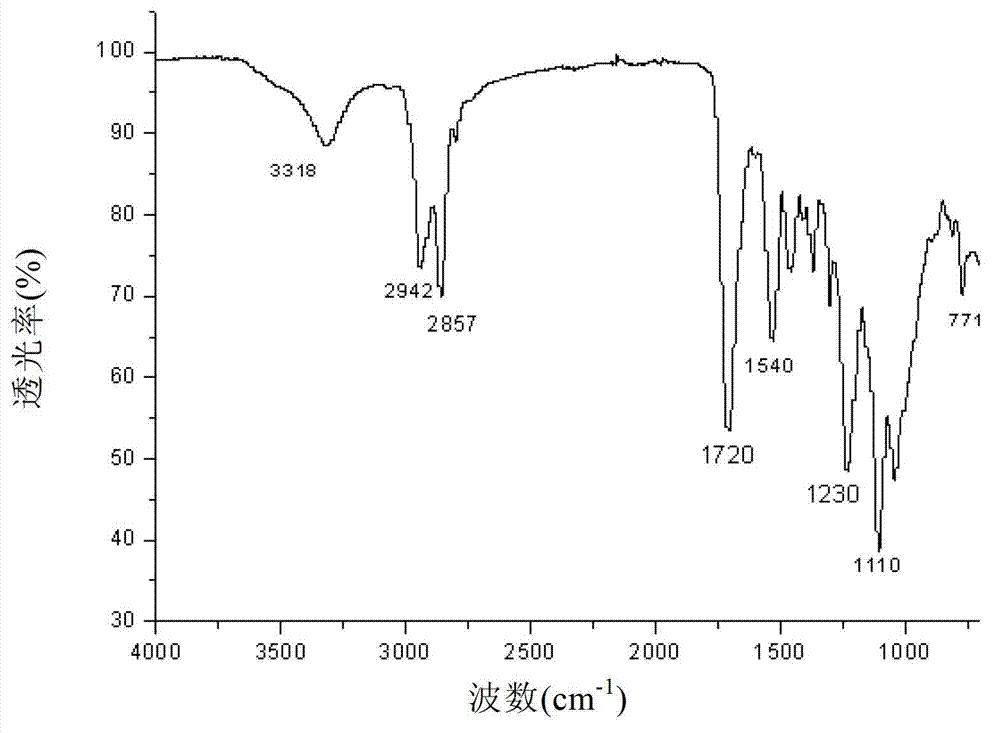

Embodiment 2

[0164] 2.1 Preparation of epoxy resin modified waterborne hyperbranched polyurethane 2

[0165] 1) Add 13.6g (0.1mol) of pentaerythritol and 53.64g (0.4mol) of dimethylolpropionic acid (DMPA) into a four-necked flask equipped with mechanical stirring, a thermometer, and a condenser, and react at 140-160°C after mixing 2.5h, under vacuum conditions (below 740mmHg), a transparent yellowish liquid is obtained;

[0166] Then add 107.28g (0.8mol) DMPA to the transparent yellowish liquid, and react at 140-160°C under vacuum conditions (below 740mmHg), until the acid value of the resin is less than 20mg KOH / g, and the reaction is terminated , poured out, and after cooling, a yellowish transparent or translucent solid was obtained, which was denoted as A1-2 (the molar ratio of dimethylol propionic acid and pentaerythritol was 12 / 1).

[0167] 2) Dissolve 18.94g of A1-2 (0.0121mol) in 50g of N-methylpyrrolidone, add 8.57g (0.085mol) of succinic anhydride, and react at 100°C for 36 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com