Construction method of soil mixing wall (SMW) engineering method

A construction method and technology of construction method, applied in basic structure engineering, construction, sheet pile wall and other directions, can solve the problems of increasing the difficulty of inserting section steel, no alignment device for H section steel, reducing strength, etc., saving cement and improving construction efficiency. , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

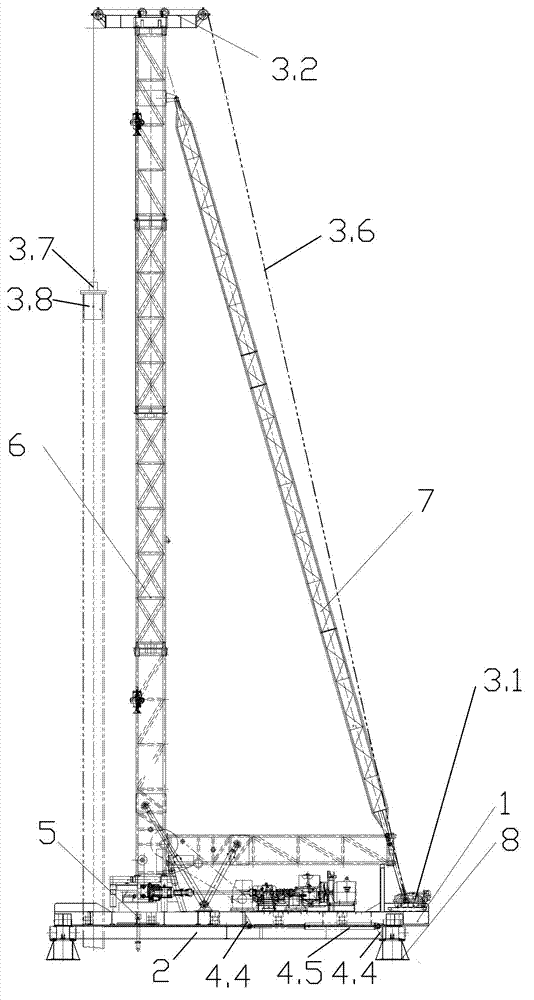

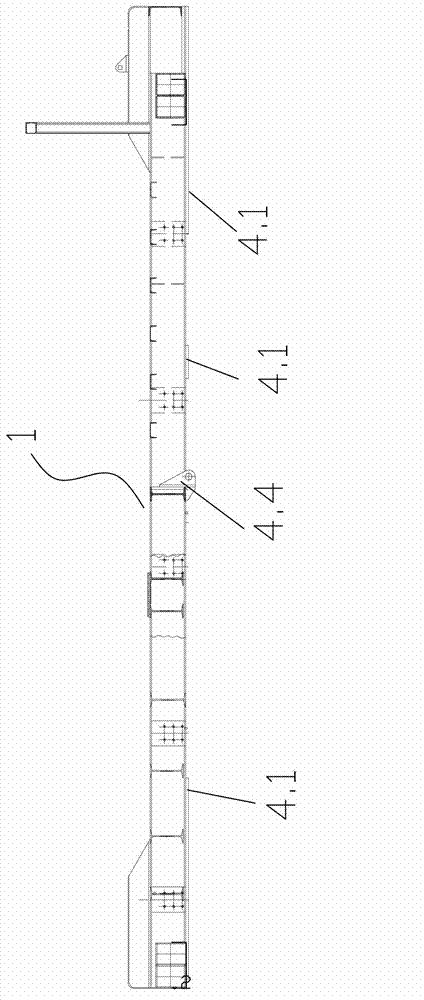

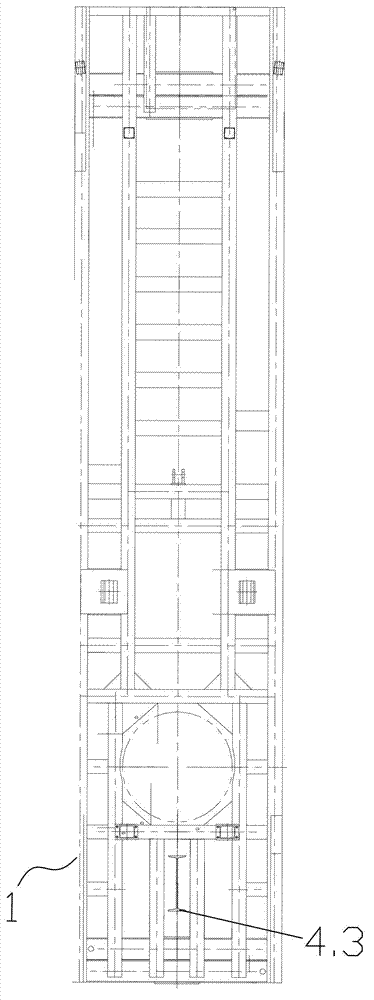

[0047] Examples, see Figure 1 to Figure 5 , the construction method of a kind of SMW engineering method provided by the invention, it comprises the following steps:

[0048] (1) Set up a SMW construction method pile driver, the SMW construction method pile driver includes a drilling tool assembly 5, a stand assembly 6, a strut assembly 7, a foot 9, a ram 8, an oil pump motor assembly, an oil tank assembly, Pressurization assembly, turntable assembly, vibratory hammer 3.8, hook 3.7, the drilling tool assembly 5 includes a drill bit, a hollow drill rod, the vibratory hammer 3.8 is connected to the hook 3.7; the drilling tool assembly 5. Stand assembly 6, strut assembly 7, foot 9, ram 8, oil pump motor assembly, fuel tank assembly, pressurization assembly, and turntable assembly are arranged on the upper chassis 1;

[0049] (2) A sky beam assembly 3.2 is arranged at the upper end of the stand assembly 6, and the sky beam assembly 3.2 includes a pulley block 3.5;

[0050] (3) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com